Fluorescent response thin-film material having humidity sensitive characteristics and preparation method thereof

A technology of fluorescent response and thin film materials, applied in the field of fluorescent response thin film materials and their preparation, to achieve the effect of broadening the application space and the range of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Weigh 0.0265g (4-(4-(dimethylamino) styryl) pyridine compound DSP, and 5.3g polyvinylpyrrolidone PVP;

[0027] 2) Mix the two evenly, put them into 15ml of methanol solution, and stir for two hours at 3000r / min in a 20ml beaker;

[0028] 3) Preparation of fluorescent film:

[0029] a. Preparation of the electrospinning instrument: adjust the distance between the needle and the collection screen to 17cm; the humidity in the instrument is 30%; the temperature is 50°C; the shape of the needle of the spinneret is selected as round;

[0030] b. Add the methanol solution containing DSP and PVP into the nozzle device;

[0031] c. Applying a high voltage of 22KV, the solution is converted into a charged jet under the action of the high voltage, and the jet is deposited on the surface of the substrate;

[0032] d. And the polymer in the jet solidifies to form nanofibers, eventually forming a white film under natural light.

Embodiment 2

[0034] 1) Weigh 0.0530g (4-(4-(dimethylamino) styryl) pyridine compound DSP, and 5.3g polyvinylpyrrolidone PVP;

[0035] 2) Mix the two evenly, put them into 25ml of methanol solution, and stir for two hours at 2000r / min in a 50ml beaker;

[0036] 3) Preparation of fluorescent film:

[0037] a. Preparation of the electrospinning instrument: adjust the distance between the needle and the collection screen to 17cm; the humidity in the instrument is 25%; the temperature is 50°C; the shape of the needle of the spinneret is selected as round;

[0038] b. Add the methanol solution containing DSP and PVP into the nozzle device;

[0039] c. Applying a high voltage of 22KV, the solution is converted into a charged jet under the action of the high voltage, and the jet is deposited on the surface of the substrate;

[0040] d. And the polymer in the jet solidifies to form nanofibers, eventually forming a white film under natural light.

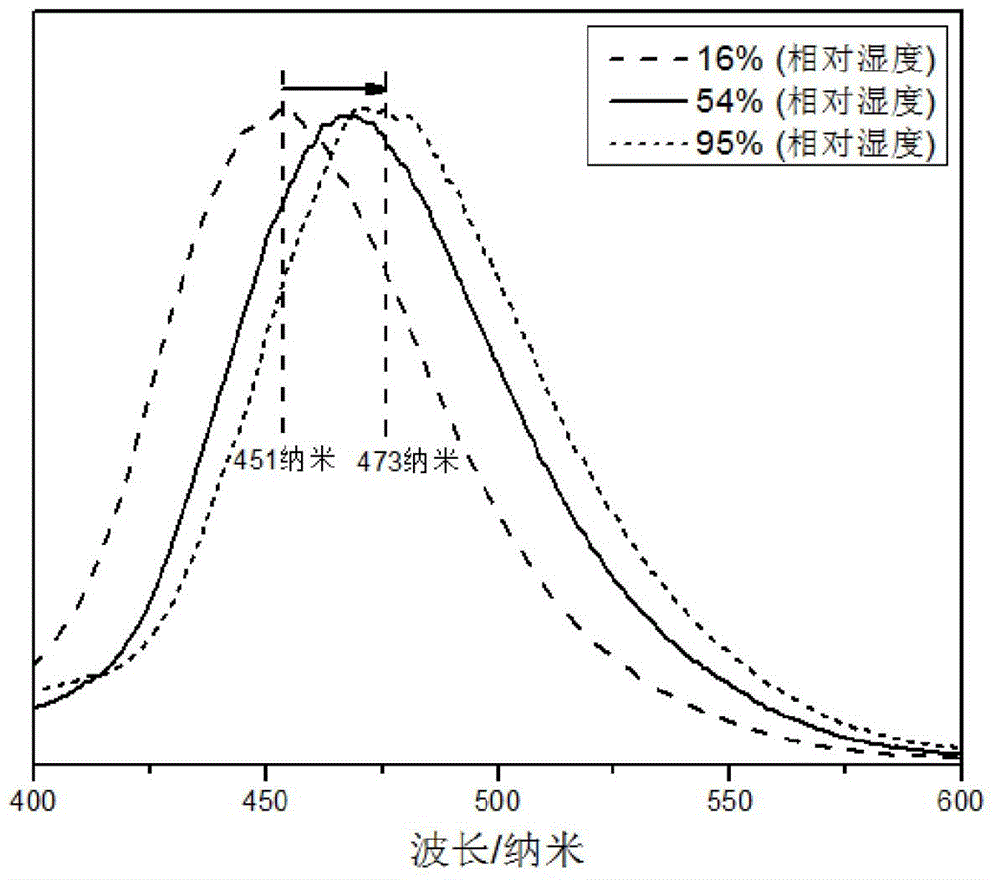

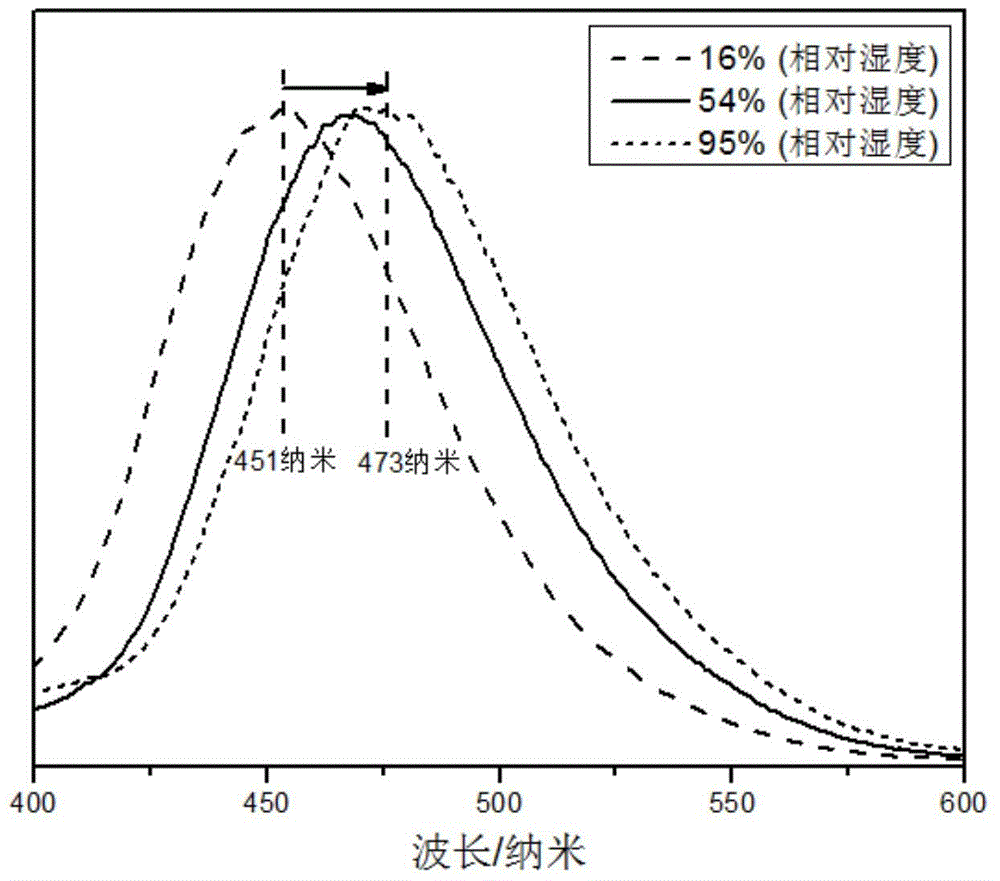

[0041] Characterization of the products in Examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com