Spray adhesive and preparation method thereof

A technology for spraying glue and synthesizing rubber, which is applied in the direction of adhesives, rosin adhesives, adhesive additives, etc., can solve problems such as permeability not involved, and achieve the effects of good construction application performance, reduced penetration time, and excellent comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

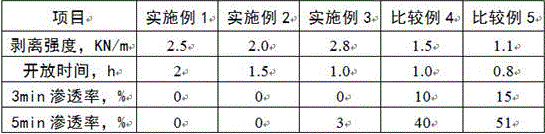

Examples

Embodiment 1

[0027] Proportion by weight, add 4 parts of methyl acetate, 4 parts of acetone, 2 parts of dimethyl carbonate, 10 parts of 6# solvent oil, and add 20 parts of hydrogenated rosin, 10 parts of petroleum resin, terpene resin 20 parts, 10 parts of SBS thermoplastic elastomer, stir until dissolved evenly; add 0.077 parts of bentonite, 0.019 parts of nano diatomite, 0.004 parts of silane coupling agent KH-550, stir well and continue to disperse for 10 minutes, add 0.1 part of zinc acrylate , Stir well and then cool and discharge.

Embodiment 2

[0029] According to the proportion by weight, add 3 parts of ethanol, 5 parts of sec-butyl acetate, 12 parts of methylal, 20 parts of petroleum ether, and add 10 parts of hydrogenated rosin, 15 parts of terpene resin, and 5 parts of glycerin rosin parts, 15 parts of SIS thermoplastic elastomer, stir until dissolved evenly; add 1.29 parts of bentonite, 0.48 parts of nano-diatomaceous earth, 0.23 parts of silane coupling agent A-171, stir well and continue to disperse for 20 minutes, add 0.3 parts of zinc diacrylate , after stirring evenly, cool and discharge.

Embodiment 3

[0031] According to the proportion by weight, add 5 parts of cyclohexane, 15 parts of methyl acetate, 5 parts of dimethyl carbonate, 10 parts of acetone, 20 parts of 6# solvent oil, and add 15 parts of phenolic resin, rosin and glycerin under stirring 40 parts of ester, 10 parts of petroleum resin, 20 parts of neoprene rubber A30, stir until dissolved evenly; add 3.12 parts of calcium sulfate whiskers, 1.25 parts of nano diatomite, 0.63 parts of silane coupling agent KBM-602, stir well and continue to disperse After 30 minutes, 0.5 part of zinc stearate was added, stirred evenly, and then cooled and discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com