Method for utilizing titaniferous electric furnace slag for direct electrolysis to produce low-titanium-aluminum alloy

A technology of titanium electric furnace slag and titanium-aluminum alloy, which is applied in the field of production of low-titanium aluminum alloy, can solve the problems of rutile titanium resource reduction, high cost, and high energy consumption in aluminum alloy industrial production, and achieve shortened utilization process, low cost, and efficient process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

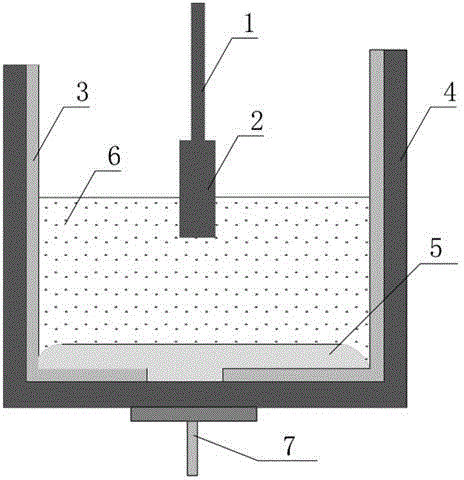

[0015] The invention is carried out in a small molten salt electrolysis test tank. The electrolytic test cell is composed of a corundum crucible (3) and a graphite crucible (4). In the upper part, the graphite guide rod (1) is connected to the carbon anode (2) to form the anode part, and the current electrolyte (6) for aluminum electrolysis production is added to the tank, and the cathode guide rod (7) is connected to the graphite crucible (4).

[0016] The titanium-containing electric furnace slag is directly added to the small molten salt electrolysis test cell, and its composition is: TiO 2 : 50.62%, Al 2 o 3 : 19.01%, MgO: 12.35%, CaO: 4.52%, SiO 2 : 8.3%, V 2 o 5 : 0.21%, TFe: 1.52%, others: 3.47%. The technical conditions of the electrolysis process are as follows: electrolysis temperature 950°C-960°C, pole distance 38-42cm, aluminum liquid level 18-22cm, electrolyte molecular ratio 2.3-2.45, electrolysis current density 0.78-0.8A / cm 2 , the electrolysis time is 1...

Embodiment 2

[0018] The titanium-containing electric furnace slag is directly added to the small molten salt electrolysis test cell, and its composition is: TiO 2 : 50.62%, Al 2 o 3 : 19.01%, MgO: 12.35%, CaO: 4.52%, SiO 2 : 8.3%, V 2 o 5 : 0.21%, TFe: 1.52%, others: 3.47%. The technical conditions of the electrolysis process are as follows: electrolysis temperature 950°C-960°C, pole distance 38-42cm, aluminum liquid level 18-22cm, electrolyte molecular ratio 2.3-2.45, electrolysis current density 0.78-0.8A / cm 2 , the electrolysis time is 18h, and the electrolyte quality is 720g. Add 7.2g of high-titanium electric furnace slag to the small-scale electrolytic test cell. Under the action of direct current, the cathode begins to precipitate metal aluminum and metal titanium, and finally forms a low-titanium alloy with a titanium content of 0.93%. content of aluminum alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com