Environment-friendly oil dipping device

An oil filter and environmental protection technology, applied in sewing equipment, textiles and papermaking, sewing machine components, etc., can solve the problems of unable to find the oil amount of sewing thread, difficult to save oil control time, low work efficiency, etc. The effect of great space potential and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

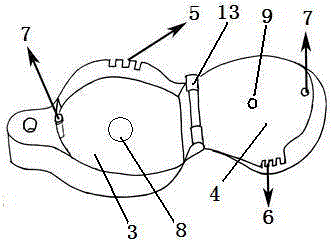

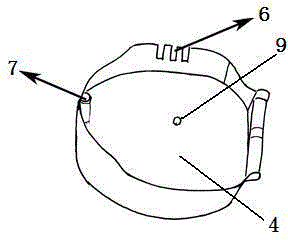

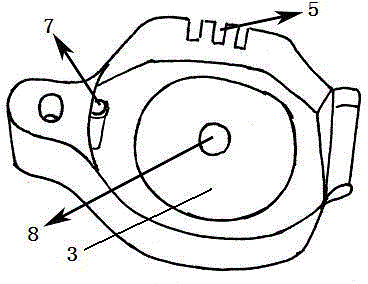

[0022] The present invention provides a Figure 1 to Figure 4 The shown environmental protection oil filter includes an oil storage bin 2 and a base 1 that is fastened together with the bottom of the oil storage bin 2. The base 1 is provided with a groove-3, and the bottom lower surface of the oil storage bin Features groove II 4, such as figure 1 As shown; when the bottom of the base 1 and the oil storage tank 2 are buckled together, the groove one 3 and the groove two 4 can be buckled together to form a cavity, and the edge of the groove one 3 is provided with a The inlet and outlet trunking one 5, the edge of the groove two 4 is provided with the inlet and outlet trunking two 6 leading to the outside; when the groove one 3 and the groove two 4 are fastened together, the inlet and outlet trunking one 5 does not coincide with the inlet and outlet slots 2 6; the middle part of the groove 2 4 is provided with an oil hole 9, and the cavity formed when the groove 1 3 and the gro...

Embodiment 2

[0025] On the basis of Example 1, such as figure 1 As shown, the base 1 is connected to the bottom of the oil storage bin 2 through a hinge 13 . The edges of the first groove 3 and the second groove 4 are each provided with a magnetic buckle 7 that cooperates and attracts each other so that the two grooves can be fastened together. The diameter of this magnetic buckle 7 is 5mm. Groove one 3 and groove two 4 are specifically annular grooves. The middle part of described groove one 3 is provided with the magnetic force button two 8 that diameter is 10mm, and this magnetic force button two 8 can be directly adsorbed on the sewing machine head and plays the effect of fixing the present invention, because general sewing machine head is iron so can Attach magnetic closure. Such as Figure 4 As shown, the top of the oil storage bin 2 is provided with an oil box cover 10, in order to ensure that the oil hole can be opened or closed at any time and the amount of oil passing through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com