Automatic clothes drying rack with reduction gears

A technology of deceleration device and clothes hanger, which is applied in the field of clothes hangers, can solve problems such as safety accidents, wear and tear of lifting ropes, failure of clothes hanger control, etc., and achieve the effect of avoiding safety accidents and reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

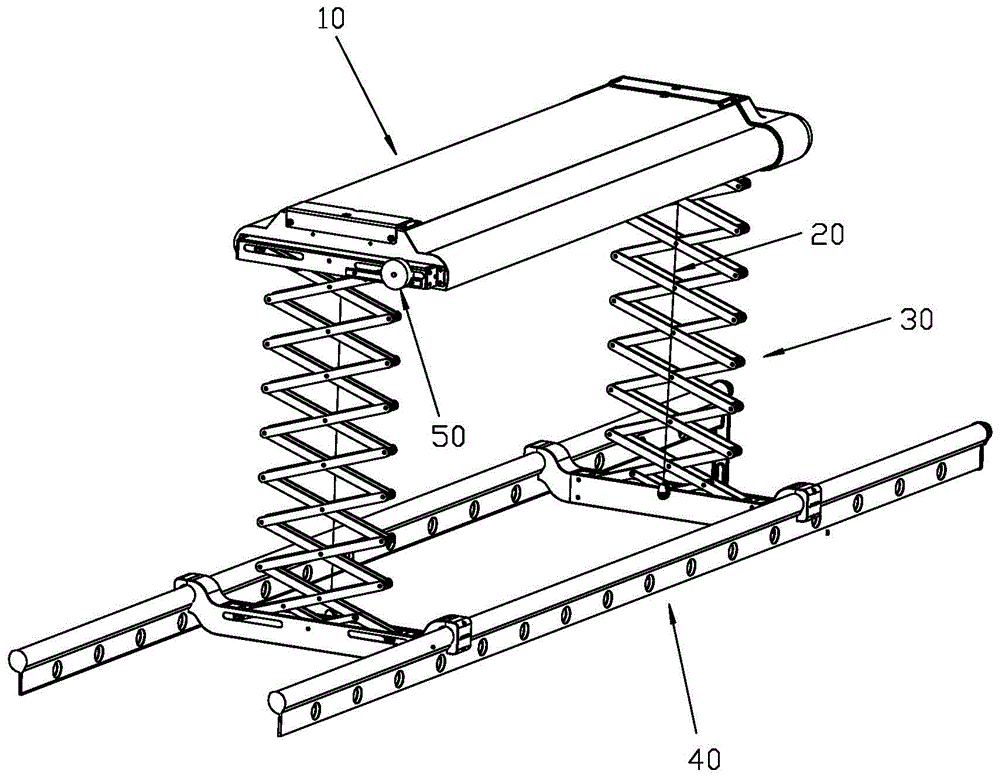

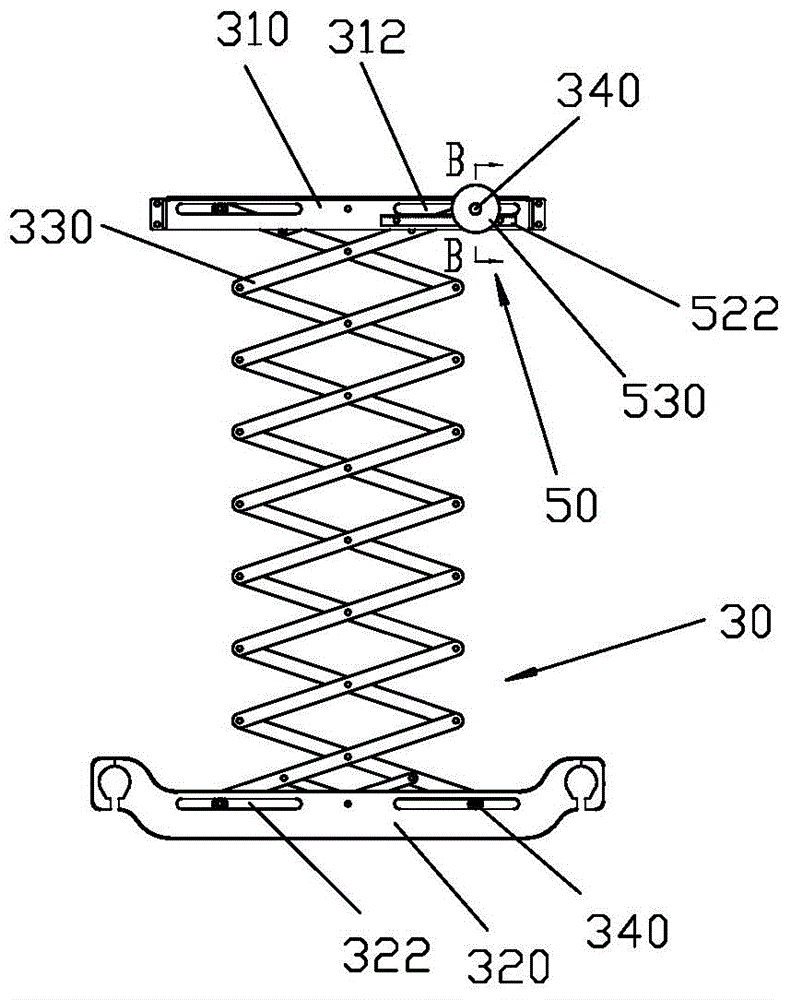

[0025] Such as Figure 1-4 As shown, the automatic drying rack of the present invention includes a body 10, a lifting rope 20, a lifting bracket 30, a drying rod 40, a deceleration device 50, and the like. The lifting bracket 30 has an upper bracket 310 fixed to the body 10 , a lower bracket 320 fixed to the drying rod 40 and a folding rod 330 between them. The upper bracket 310 is provided with a sliding slot 312 , and the upper end of the folding rod 330 is connected with a pin shaft 340 . The pin shaft 340 is inserted into the sliding slot 312 and slides in the sliding slot 312 as the folding rod 330 is unfolded and folded.

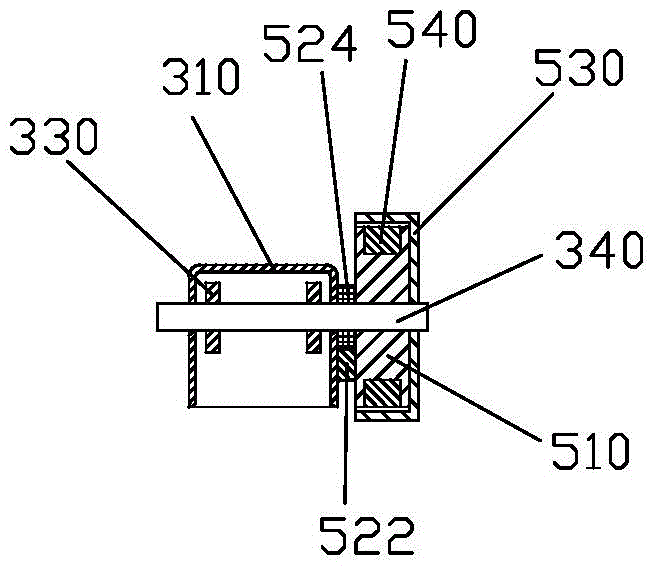

[0026] The reduction device 50 is disposed on the pin shaft 340 and includes a reduction wheel 510 , a transmission member 520 , a limiting member 530 and a brake block 540 . The deceleration wheel 510 is a cylinder including an outer peripheral surface and two side surfaces. Two semicircular annular grooves 512 are arranged on the outer peripheral su...

Embodiment 2

[0030] see Figure 5 , the automatic clothes hanger of the present invention differs from Embodiment 1 in that: the transmission part 520 also includes a planetary carrier 526 and three planetary gears 528, and the three planetary gears 528 are socketed on one side of the planetary carrier 526 and connected to the reduction gear 510 The gear 524 on the upper meshes, wherein the gear 524 acts as a sun gear. The other side of the planet carrier 526 is also fixed with a gear 526 a meshing with the rack 522 . A mounting hole is provided in the middle of the planet carrier 526 , and is sleeved on the pin shaft 340 . Teeth 536 meshing with the planetary gear 528 are disposed on the cavity wall at the opening edge of the inner cavity of the restriction member 530 . Through the arrangement of the planetary gear train, the speed of the reduction wheel 510 can be increased, and the centrifugal force of the brake block 540 can be enhanced, thereby increasing the friction force in the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com