Lateral girder erection and construction method for truss double-girder type bridge girder erection machine

A bridge erecting machine and double-girder technology, which is applied in bridge construction, erection/assembly of bridges, bridges, etc., can solve the problems of particularly unfavorable construction cost control, large limitations, and inapplicability, so as to reduce repeated installation and dismantling and The effect of appearance, strong wind resistance, and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

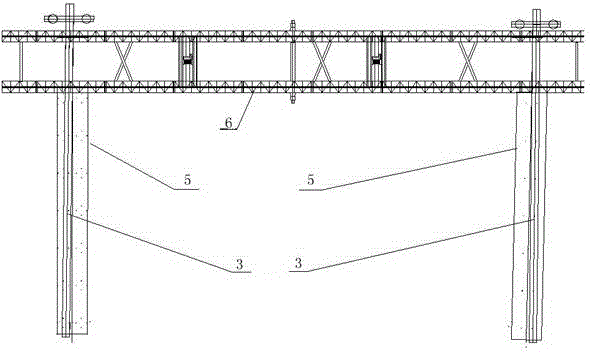

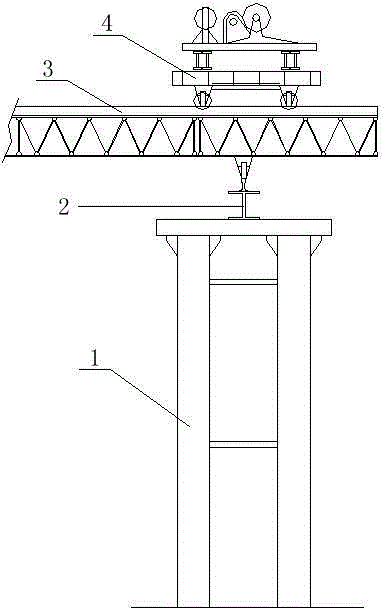

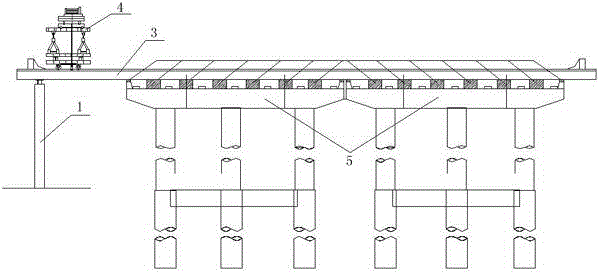

[0039] A side feeding girder erection structure of a truss double girder type bridge erecting machine, including two traverse rails respectively arranged on the top of the cover beam at both ends of the hole to be erected, the two ends of the traverse rail are suspended outside the cover beam, and the externally suspended ends Supported on temporary buttresses, the top of the two traversing tracks is equipped with a high-level gantry crane structure with traversing wheel boxes as the running system.

[0040] The temporary support pier includes a double-supported steel pipe support column arranged on the extension line of the cover beam, a pile cap is installed on the top of the steel pipe support column, and a double I-beam distribution beam is installed on the top of the pile cap.

[0041] The high-level gantry crane structure includes traversing wheel boxes respectively installed on the two traversing rails, the tops of the two traversing wheel boxes are installed with main l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com