Tiny butt weld detection system of binocular two-way convergence adjustable optical path

A technology of butt weld and detection system, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems affecting the development of automatic welding technology of small butt welds, difficult to achieve high-precision detection, and difficult to extract weld features, etc. The problem is to eliminate the gap feature extraction error, the structure is simple, and the light intensity is increased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

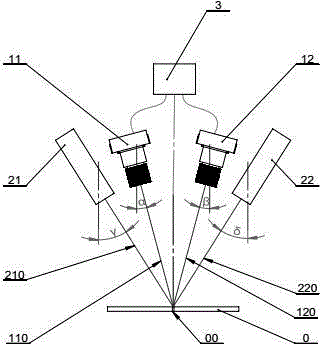

[0014] figure 1 Schematically shows a binocular two-way convergent adjustable optical path micro-butt weld detection system according to the present invention.

[0015] This embodiment provides a binocular two-way convergent adjustable optical path fine butt weld inspection system, please refer to figure 1 , comprising: an image controller 3, a first imaging device 11 and a second imaging device 12 respectively connected to the image controller 3, in this embodiment the first imaging device 11 can be a CCD camera or a CMOS camera, the described The second imaging device 12 can select a CCD camera or a CMOS camera for use, and the first imaging device 11 and the second imaging device 12 are arranged on both sides of the image controller 3, and are arranged on one side of the first imaging device 11. There is a first light source generating device 21, and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com