Internal combustion engine control circuit and internal combustion engine control method

A technology of internal combustion engine control and internal combustion engine, which is applied in the direction of motor starting for engines, machines/engines, mechanical equipment, etc., and can solve problems such as power reduction and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0033] "structure"

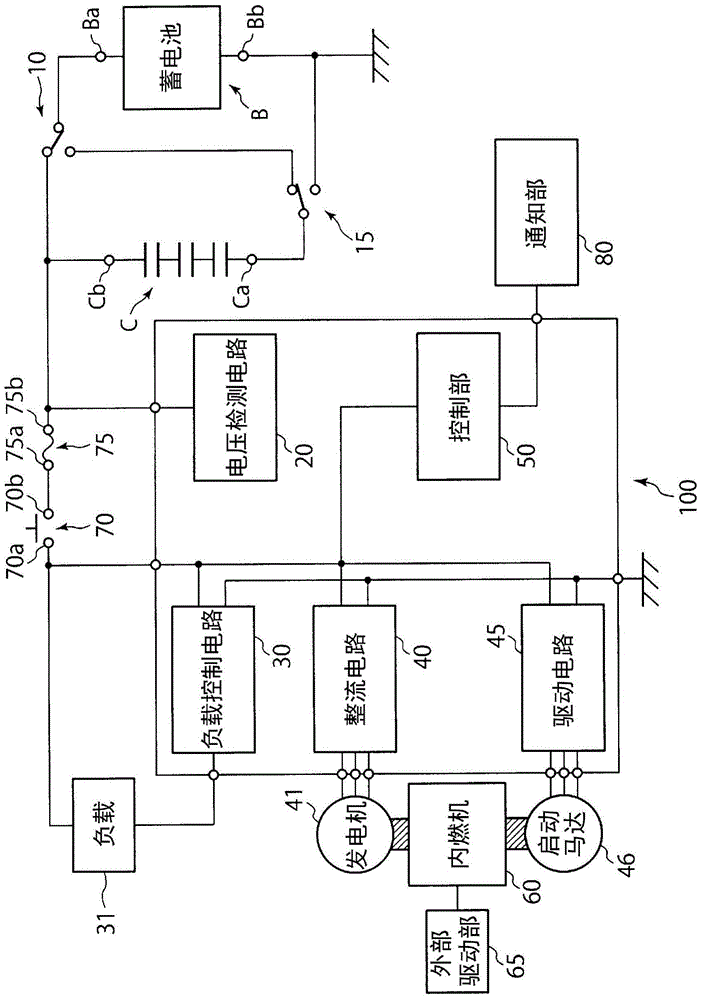

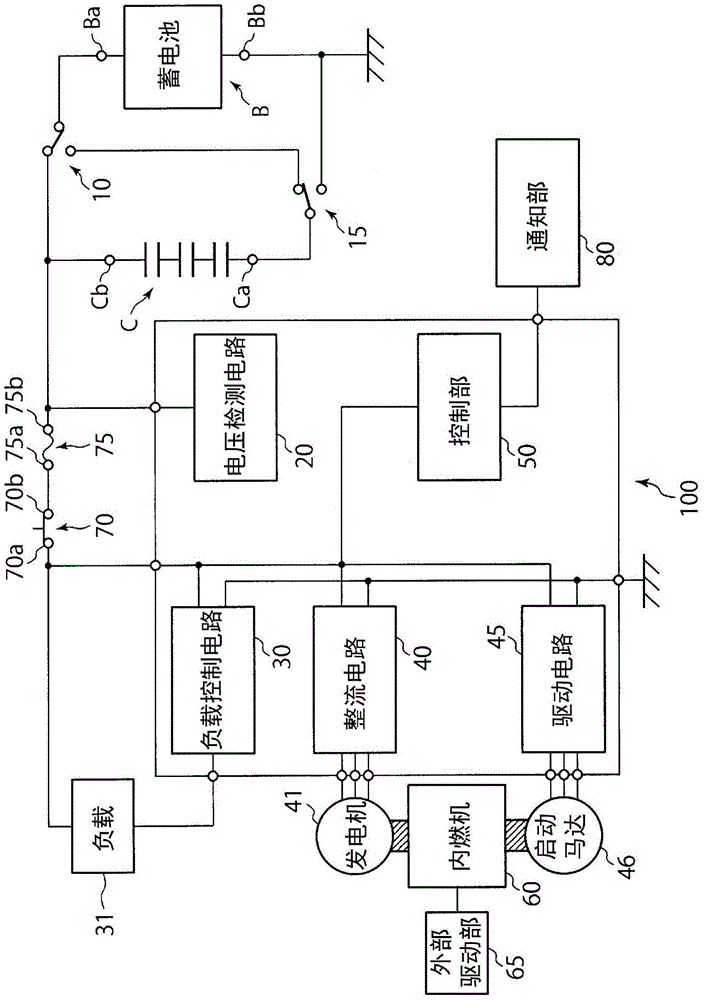

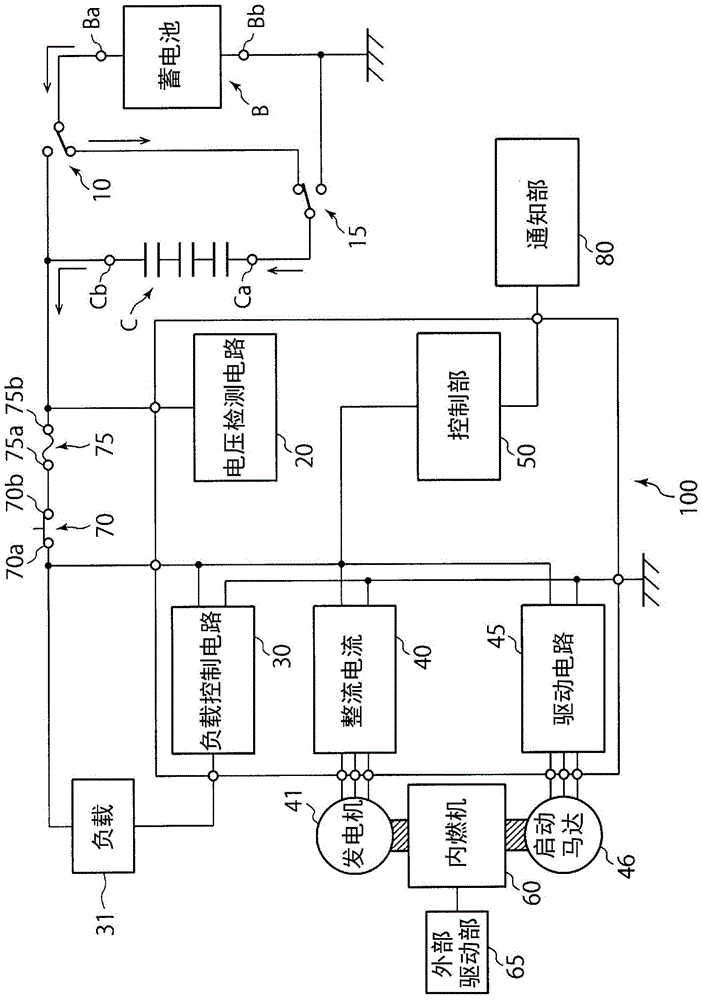

[0034] Hereinafter, Embodiment 1 of the internal combustion engine control circuit according to the present invention will be described with reference to the drawings. here, Figure 1 to Figure 6 It is a figure for demonstrating embodiment of this invention.

[0035] The internal combustion engine control circuit 100 of the present embodiment is, for example, a circuit for controlling an internal combustion engine 60 such as an engine, for example, a circuit for controlling a motor of a motorcycle engine can be taken as an example. As will be described later, the internal combustion engine 60 of the present embodiment can be started by driving an external drive unit 65 such as a kick starter. In addition, instead of using such an external drive unit 65 when starting the internal combustion engine 60, the internal combustion engine 60 may be started by, for example, pushing the motorcycle vigorously (so-called "push starter"). Such as figure 1 As shown...

Embodiment approach 2

[0078] Next, Embodiment 2 will be described. in addition, Figure 7 is a basic configuration diagram showing the internal combustion engine control circuit 100 according to Embodiment 2 of the present invention, and shows the same Figure 5 corresponding form.

[0079] In Embodiment 1, when the main switch 70 is on and the voltage generated by the generator 41 is higher than the voltage when the battery B is fully charged, as Figure 5 It is shown that the first terminal Ca of the capacitor C is connected to ground through the second switch 15, and the first terminal Ba of the battery B is connected to the second terminal 70b of the main switch 70 and the capacitor C via the fuse 75 through the first switch 10, A form in which the storage battery B and the capacitor C are connected in parallel so that both the storage battery B and the capacitor C can be charged. Regarding this point, in the second embodiment, a rotational speed detection circuit 95 for detecting the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com