Use of amine compounds in dispersing fluorocarbon materials and method for dispersing fluorocarbon materials

A technology of amine compounds and fluorocarbon materials, applied in the field of materials, can solve the problems that the dispersion of fluorocarbon materials needs to be improved and cannot be dispersed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

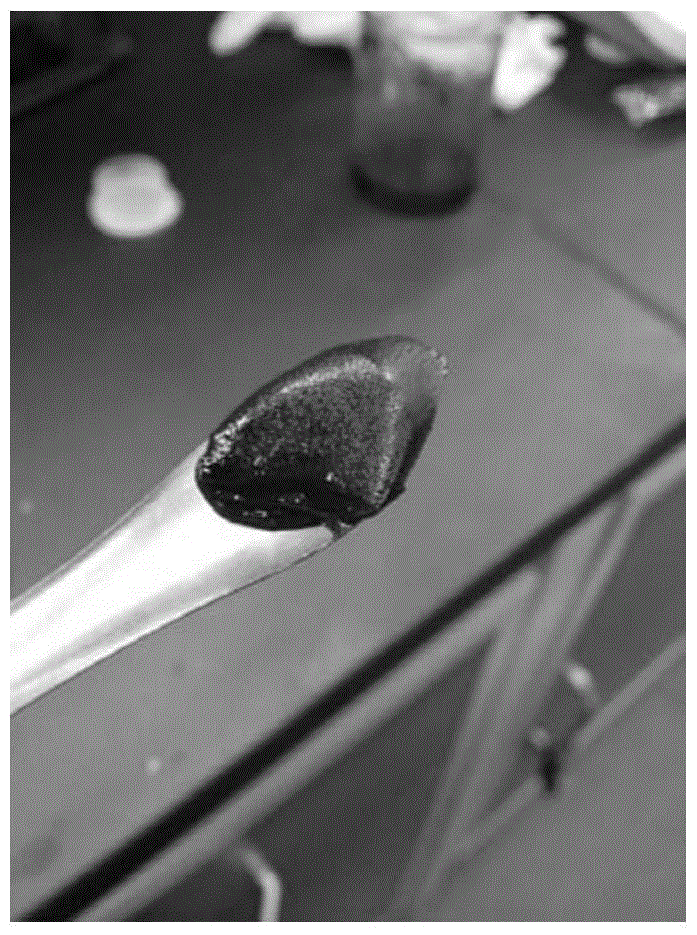

[0063] Dissolve 3 g of fluorinated graphite in 50 ml of ethanolamine, ultrasonicate the resulting mixture for 30 min, and stir at room temperature for 3 h. After stirring, the resulting mixture is in the form of a black jelly. After standing the black jelly mixture for a few days, remove the supernatant liquid (ethanolamine) and impurities, the obtained mixture was centrifuged at 10000rpm for 30min, and the oily precipitate was collected. The photo of the oily precipitate is shown in figure 2 . The main component of the greasy precipitate is graphite fluoride, which contains a small amount of ethanolamine. The volume of ethanolamine removed is measured, and the mass ratio of graphite fluoride and ethanolamine can be obtained by calculation. The results show that in the obtained greasy precipitate, the fluorine The ratio of graphite and ethanolamine is 3g:2ml.

Embodiment 2

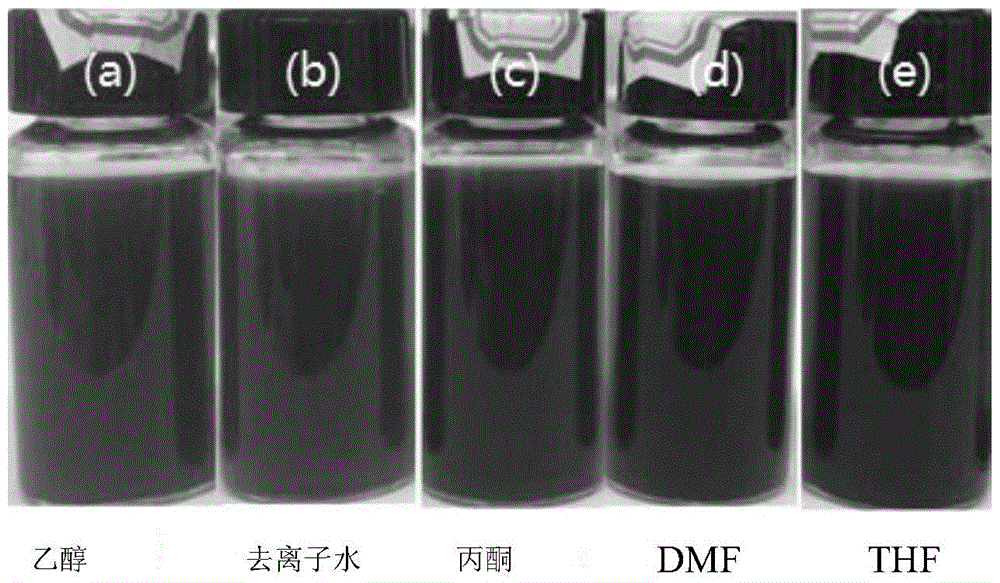

[0065] Under ultrasonic treatment conditions, add appropriate amount of the greasy precipitate prepared in Example 1 to various organic polar media acetone, N,N-dimethylformamide and tetrahydrofuran, fluorinated graphite dispersed in acetone, N, The photographs in N-dimethylformamide and THF, respectively, are in image 3 c. image 3 d and image 3 e, The results show that graphite fluoride can be stably dispersed in acetone, N,N-dimethylformamide, and tetrahydrofuran with the introduction of an appropriate amount of ethanolamine.

Embodiment 3

[0067] 1. Dispersion of graphite fluoride:

[0068] An appropriate amount of fluorinated graphite was dissolved in 10ml NPPGMA-1000 and 10ml PPGBA-230 respectively, and the mass fractions of fluorinated graphite were respectively 0.043wt%, 0.072wt%, 0.107wt% and 0.143wt% fluorinated graphite / NPPGMA The mass fractions of -1000 mixture and fluorinated graphite are respectively 0.3g / L, 0.5g / L, 1g / L, 2g / L and 5g / L fluorinated graphite / PPGBA-230 mixture, and the obtained fluorinated graphite contains The mixtures were ultrasonically treated for 30min, and then stirred at room temperature for 3h. After stirring, the resulting graphite fluoride / NPPGMA-1000 mixture was allowed to stand for a week. See Figure 4 , wherein, (a) is a photo of 0.043wt% fluorinated graphite / NPPGMA-1000 mixture, (b) is a photo of 0.072wt% fluorinated graphite / NPPGMA-1000 mixture, (c) is 0.107wt% fluorine (d) is a photo of 0.143 wt% graphite fluoride / NPPGMA-1000 mixture. The photo of the obtained fluorinat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com