Spouting fluidization machine and method for producing multi-scale solid mixtures

A multi-scale, mixture technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as knotting, clogging, and difficult separation, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

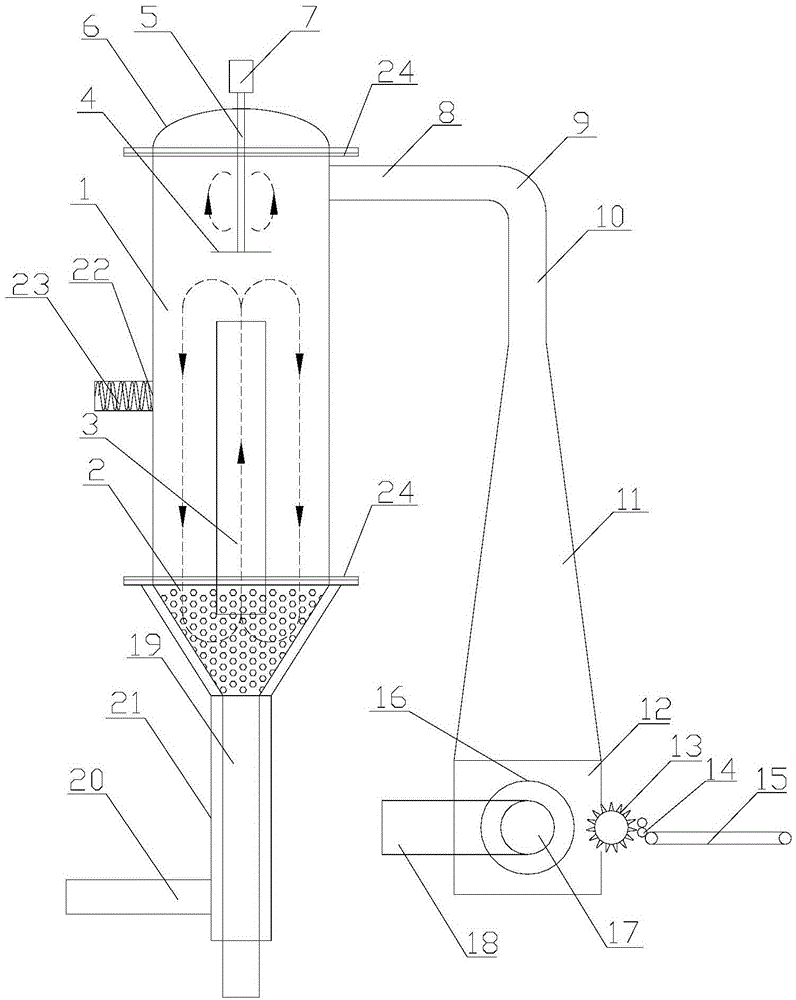

[0041] like figure 1 As shown, a multi-scale solid-phase jet fluidized dispersion mixing device includes a cylinder 1, a conical distributor 2, a stirring device, a discharge system and a pipeline cutting machine;

[0042] The top of the cylinder body 1 is equipped with a dish-shaped bottom head 6 through a flange 24, and its side wall is provided with a feed port 22 and a discharge port, and the discharge port is located above the feed port 22. The discharge system is connected to the discharge port;

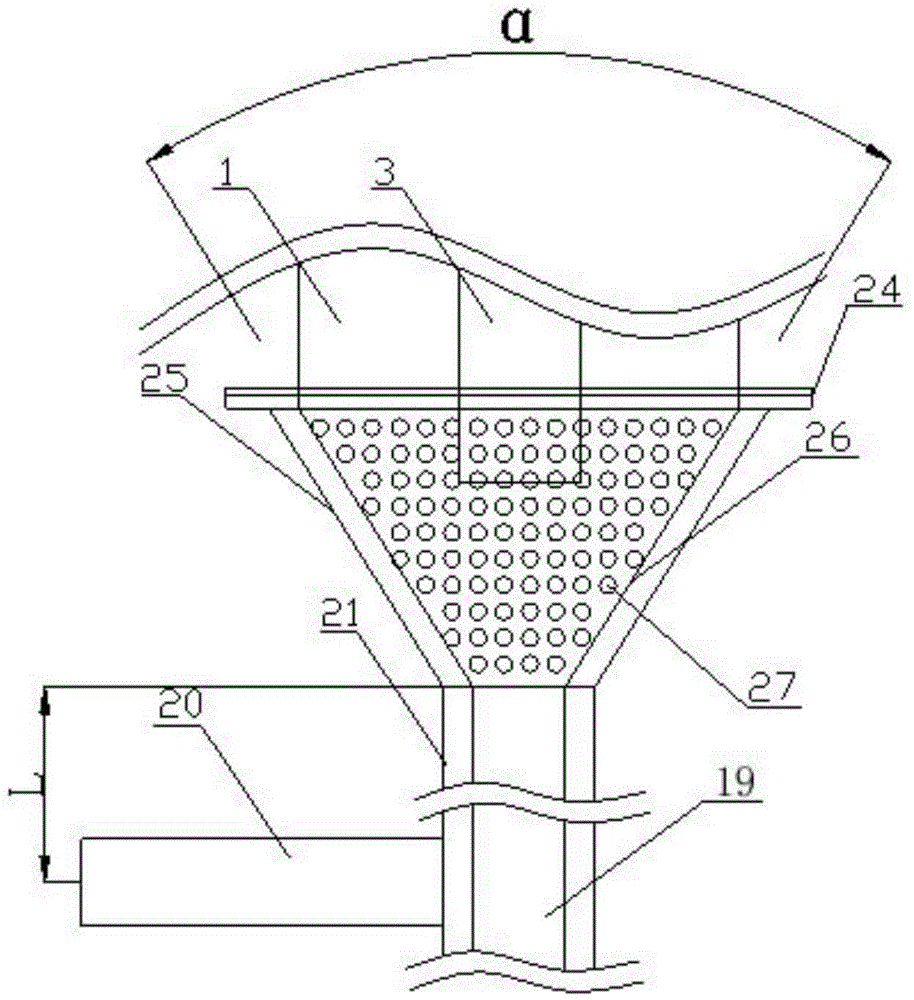

[0043] like figure 2 As shown, the conical distributor 2 is installed on the lower part of the cylinder body 1 through a flange 24, and is a double-layer structure, including an outer conical shell 25 and an inner conical body 26, the outer conical shell 25 and the inner conical shell 26. A ventilation chamber 28 is formed between the inner cones 26, and a number of distribution holes 27 for distributing gas are opened on the inner cones 26, and a fluidizing gas pipeline 21 ...

Embodiment 2

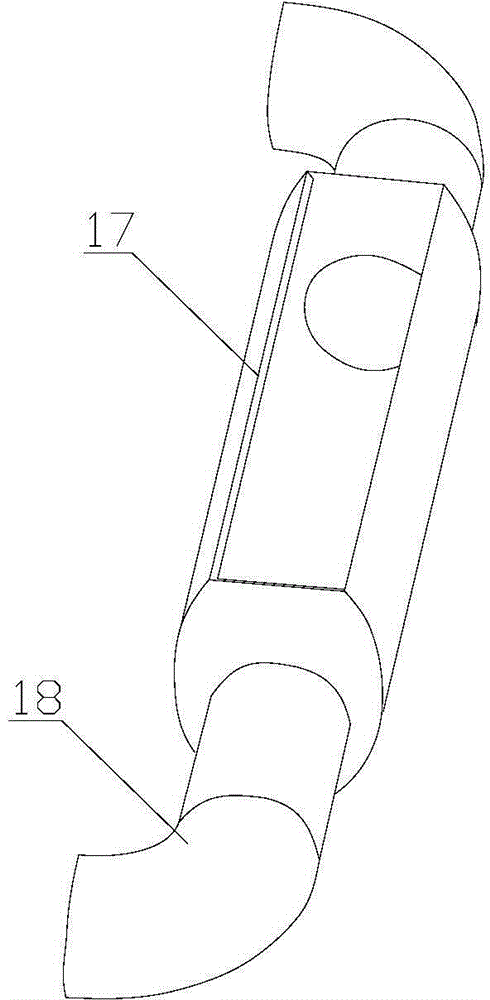

[0063] As an improvement of Embodiment 1, in order to facilitate the replacement of the cutterhead 34, the cutterhead 34 is detachably connected to the nozzle; slice 45. Other structures are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com