Improved magnet ring inductance online automatic separation equipment

A technology of automatic sorting and magnetic ring inductance, applied in sorting and other directions, can solve the problems of cumbersome operation steps, low efficiency, unstable inductance reading, etc., and achieve the effect of accurate test data, high degree of automation, and fast test speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

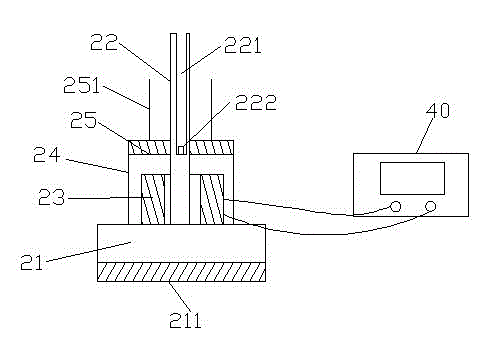

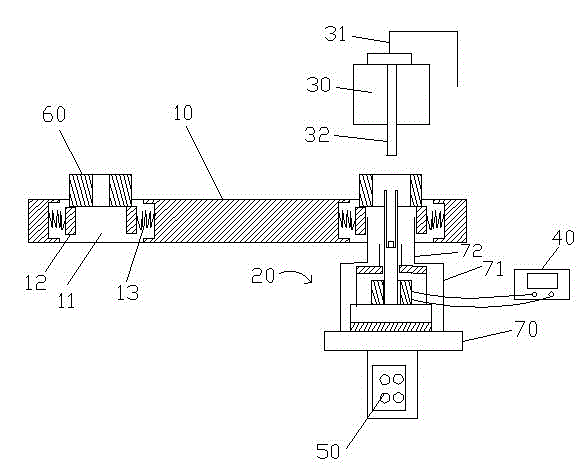

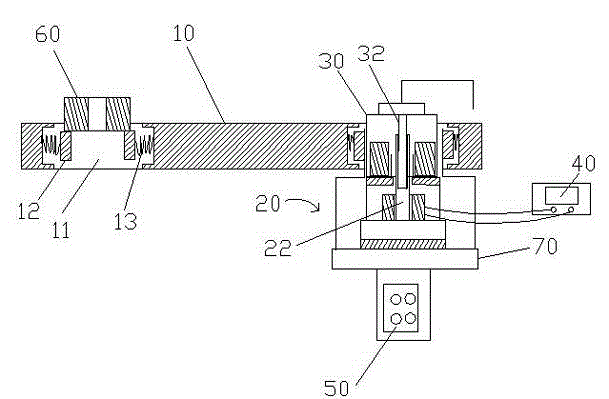

[0041] Such as figure 2 and image 3 As shown, an improved magnetic ring inductance online automatic sorting equipment includes a multi-index rotary table 10, a test stand, a jacking platform 71, an inductance tester 40, an automatic feeding device, an unloading device and integrated control of a built-in PLC. Panel 50.

[0042] The above-mentioned multi-index rotary table 10 , test seat, jacking platform 70 , inductance tester 40 , automatic feeding device and unloading device are all connected to the integrated control panel 50 .

[0043] The above-mentioned multi-index rotary table 10 is preferably connected with an indexer, and the indexer is preferably 8 indexers, and the indexer is connected with the integrated control panel 50, and the operator can set parameters such as the speed of rotation of the multi-index rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com