Worm-driven double-valve hydraulic oscillator

A technology of hydraulic oscillator and turbine, which is applied in the field of drilling tools, oil and natural gas, and can solve the problems of difficult control of vibration effect, short service life and high energy consumption, so as to reduce frictional resistance, increase mechanical speed of penetration and effective drilling pressure increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

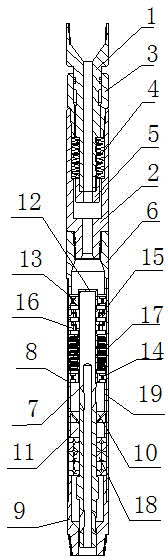

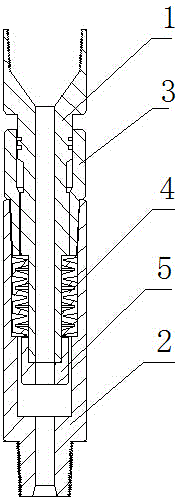

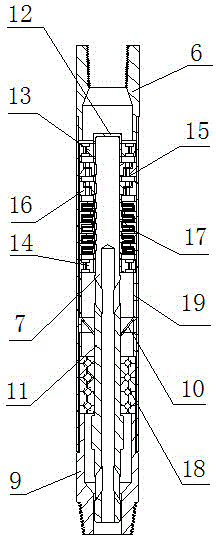

[0018] The turbine-driven double-valve hydraulic oscillator is composed of a vibration short-circuit assembly and a power short-circuit assembly; the vibration short-circuit assembly and the power short-circuit assembly are connected to each other through threads; 1. The oscillating shell 2, the coupling sleeve 3, the pressure spring 4 and the compression nut 5 are composed; the spline mandrel 1 is installed on the oscillating shell 2 through the coupling sleeve 3; the oscillating shell 2 and the coupling sleeve 3 are threadedly connected , The sliding connection between the coupling sleeve 3 and the splined mandrel 1. A compression nut 5 is threadedly mounted on the lower end of the splined mandrel 1 in the oscillating housing 2 ; a compression spring 4 is installed on the splined mandrel 1 between the compression nut 5 and the coupling sleeve 3 .

[0019] The power shorting assembly is composed of a compression sleeve 6, a turbine shaft 7, a main engine housing 8, a lower jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com