Polyamide-6 granula nitrogen drying heat exchange system

A nitrogen drying and heat exchange system technology, applied in the directions of drying gas arrangement, drying, drying machine, etc., can solve the problems of energy waste, multi-heat energy, lack of comprehensive utilization of energy, etc., and achieve the goal of reducing energy consumption and production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

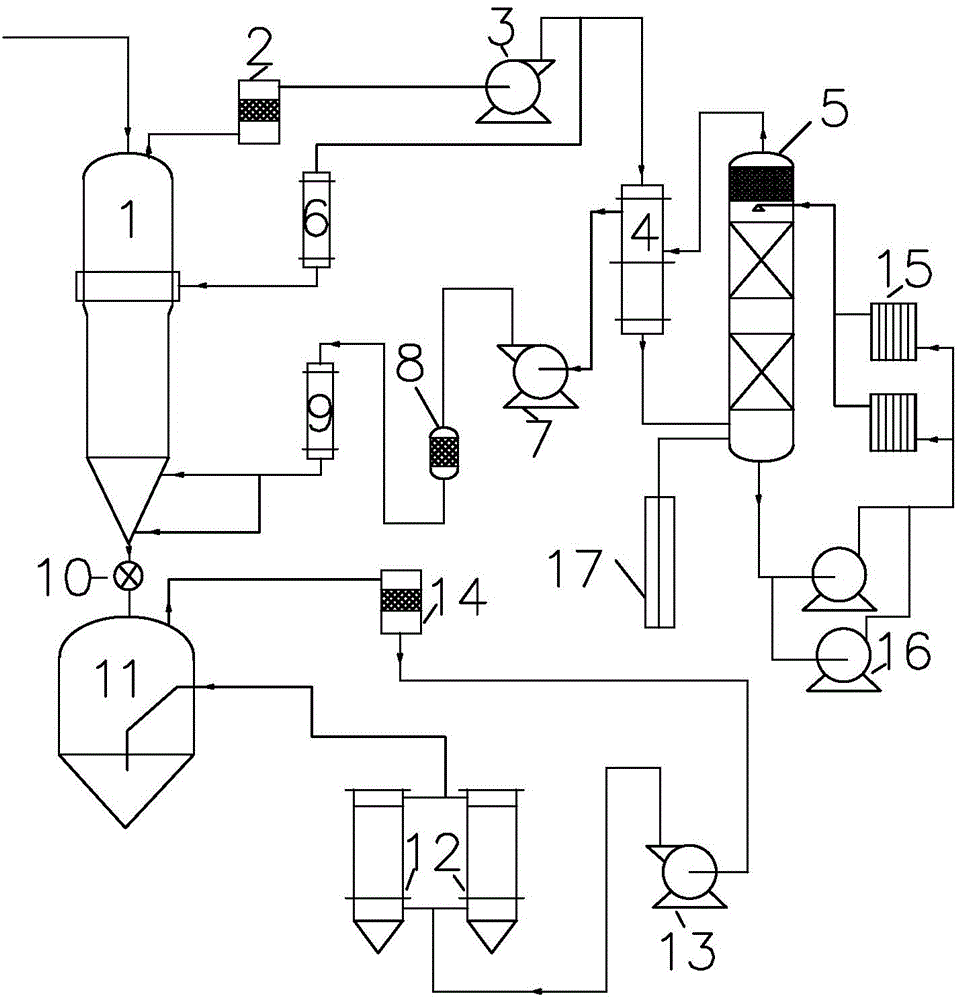

[0022] Such as figure 1 As shown, a nylon 6 slice nitrogen drying heat exchange system,

[0023] It mainly includes slice cooling chamber system, drying tower, nitrogen filter 1, nitrogen circulation fan 1, nitrogen circulation fan 2, nitrogen heat exchanger, spray cooling system, nitrogen heater 1, nitrogen heater 2 and nitrogen purification device;

[0024] The hot and humid nitrogen is discharged from the top of the drying tower 1 (temperature is 110-120 degrees), and is transported to the nitrogen circulation fan 3 through the nitrogen filter 1. The nitrogen from the nitrogen circulation fan 1 is divided into two paths, and one path is exchanged with nitrogen. The device 4 enters the spray cooling tower 5 (spray water temperature ≤ 20 degrees) in the spray cooling system, and the other path is heated by the nitrogen heater 6 and then transported to the nitrogen inlet in the middle of the drying tower;

[0025] After the nitrogen in the spray cooling tower 5 is cooled, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com