An integrated purification and energy-saving system and process

A technology of an energy-saving system and a flue gas purification system, which is applied to the flue gas purification system and process field of a coke oven or a pyrolysis furnace, and can solve the problems of waste of resources, waste of waste heat, waste of energy and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

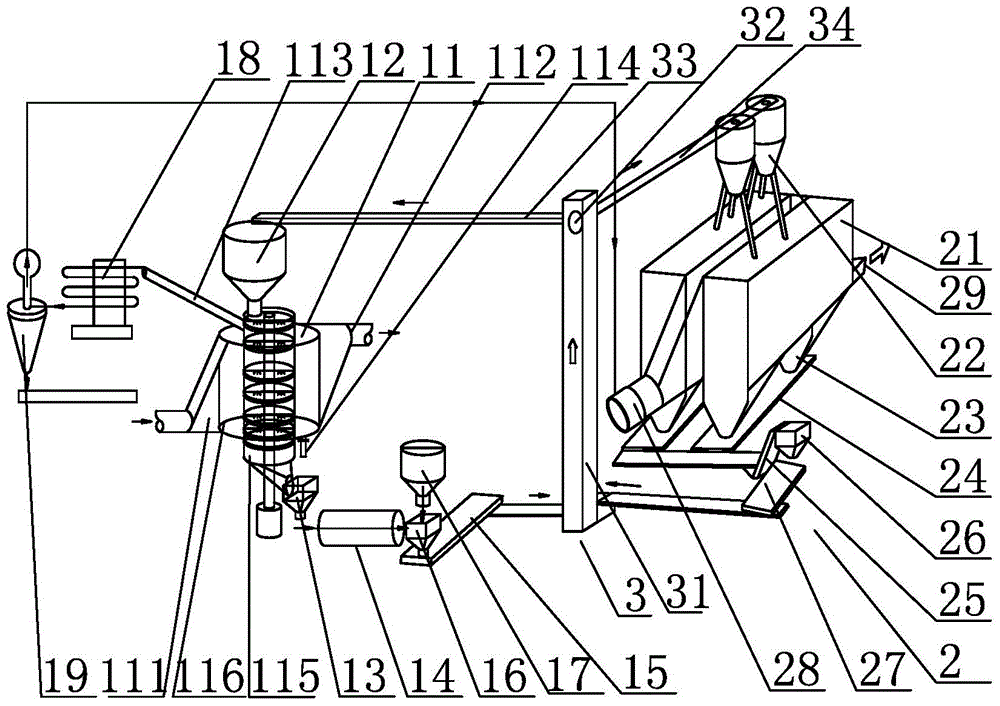

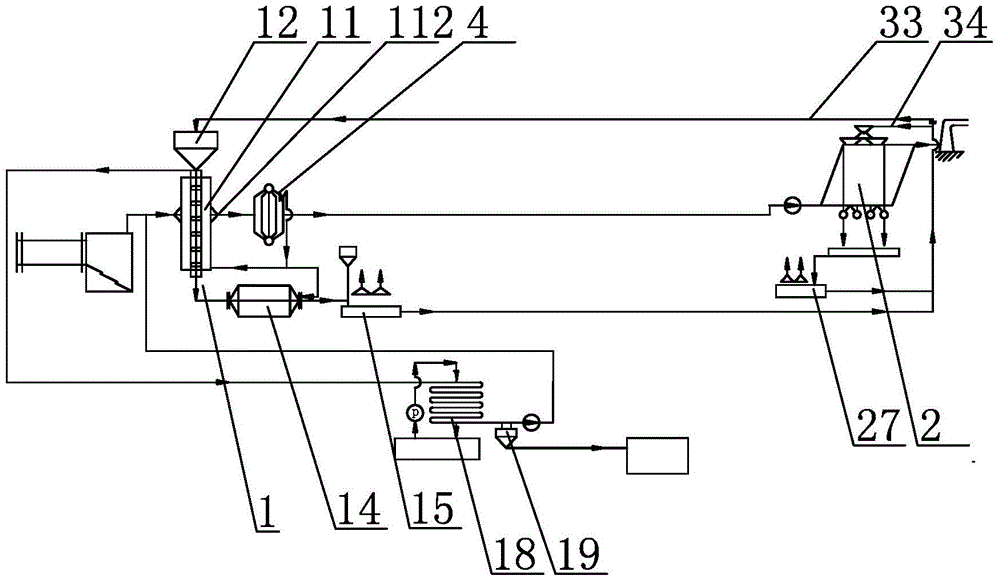

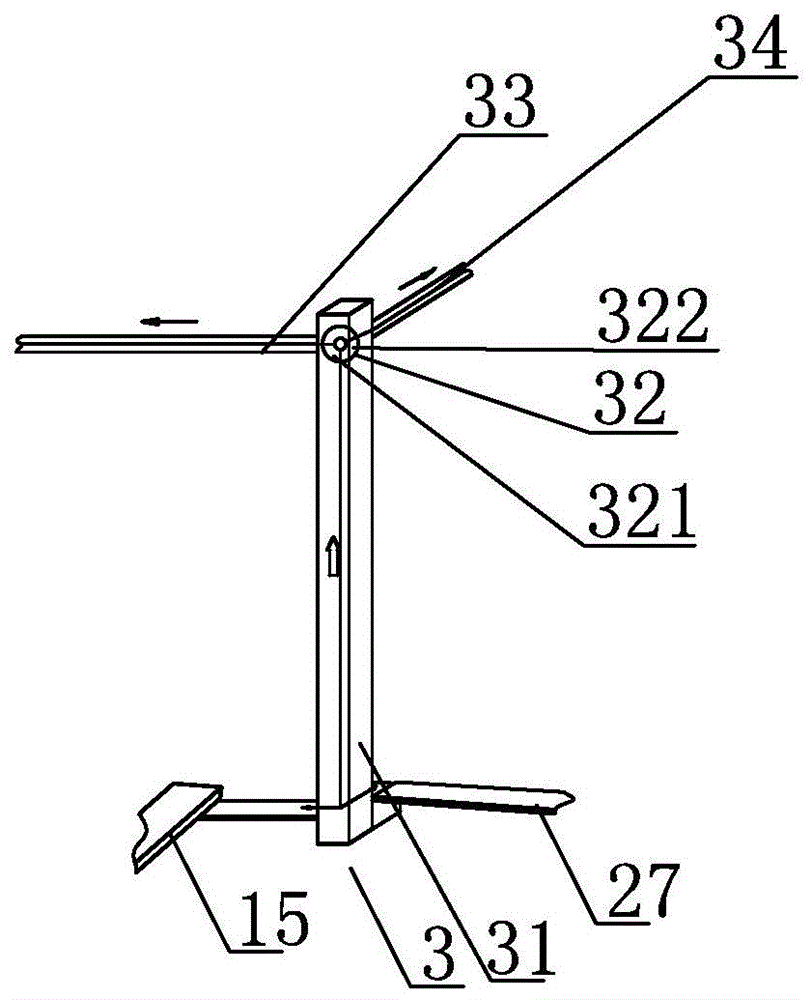

[0034] Such as Figure 1-4 As shown, the transfer device 3 includes a driving device (not shown in the figure) and a coke transport pipeline. The coke transport pipeline includes a main coke transport channel 31, and the output end of the main coke transport channel 31 is divided into two coke transport branches. The coke transportation branch 33 leads to the saturated coke bucket, and the second coke transportation branch 34 leads to the new coke warehouse, wherein the main coke transportation road 31 has two implementation modes, as follows:

[0035] Such as Figure 4 As shown, the inside of the main coke track 31 is provided with a first main coke track 311 and a second main coke track 312, the first main coke track 311 and the second main coke track 312 are independent of each other, and each is driven by a Driven by the device, under the drive of the driving device, the new coke enters into the new coke bin through the first screening and dust removal device 15, the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com