Engine stability scaling method

An engine and stability technology, applied in jet engine testing, gas turbine engine testing, etc., can solve problems such as difficult combustion stability similarity research, not similarity scaling design, and difficult to ensure similar flow field, etc., to achieve Simple structure, reduced mass flow rate and combustion chamber pressure, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]The present invention will be further described in detail below by taking a certain type of high-pressure supplementary combustion cycle engine as a preferred embodiment. A certain type of high-pressure afterburning cycle engine, that is, the full-scale engine described below, uses a gas-liquid coaxial centrifugal nozzle, and the propellant is liquid oxygen / kerosene.

[0034] In order to facilitate the detailed introduction of subsequent embodiments, the following letters are explained as follows:

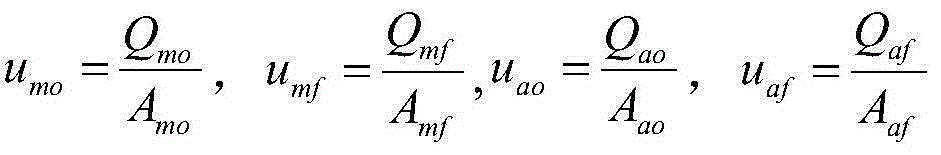

[0035] Q mo is the oxygen volume flow rate of the single nozzle of the scaled engine;

[0036] Q mf is the gasification kerosene volume flow rate of the single nozzle of the scaled engine;

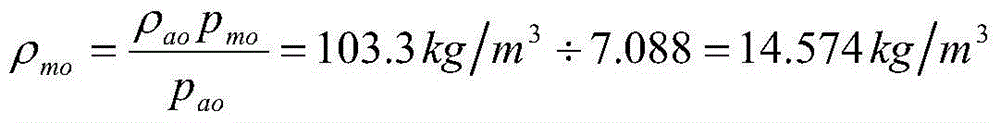

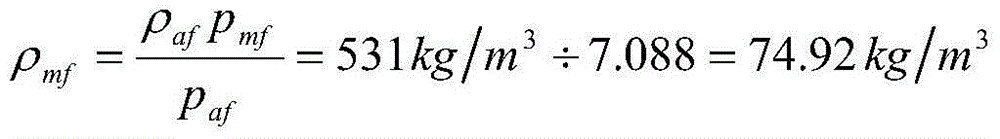

[0037] ρ mo is the oxygen density of the single nozzle of the scaled engine;

[0038] p mo is the combustion chamber pressure of the scaled engine;

[0039] ρ ao is the single-nozzle oxygen jet density for a full-scale engine;

[0040] p ao is the combustion chamber pressure of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com