Horizontal CCD (charge-coupled device) two-sided line scanning system

A scanning system and horizontal scanning technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problem of circular boards, special-shaped boards that cannot be scanned vertically, and cannot be cleaned by adding adhesive layer rollers to the board surface, and soft boards. Problems such as inability to scan upright can achieve the effect of reducing manpower, increasing output, and reducing false positives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

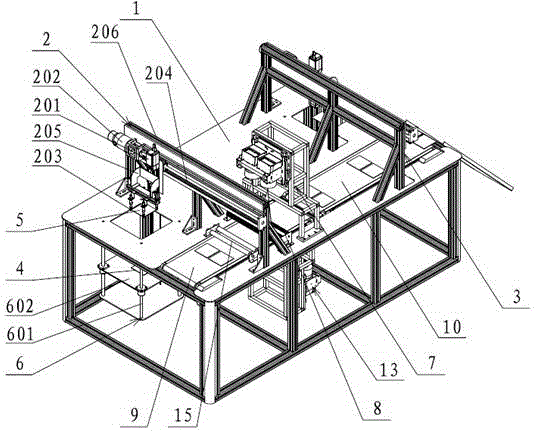

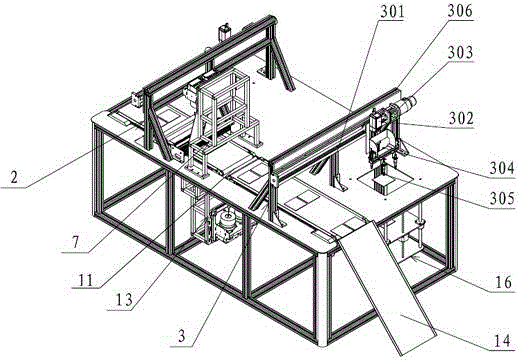

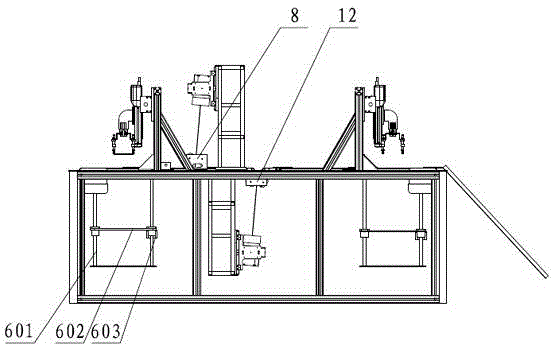

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] As shown in the figure, the horizontal CCD double-sided line scanning system includes a horizontal scanning system bracket 1, and the two ends of the horizontal scanning system bracket 1 are provided with a feeding mechanism 2 and a feeding mechanism 3, and a feeding device 6 is correspondingly installed under the feeding mechanism 2. The discharge device 16 is arranged correspondingly below the discharging mechanism 3, and the upper CCD scanning mechanism 7 is arranged between the material taking mechanism 2 and the discharging mechanism 3, and the first LED controllable light source lighting device 8 is correspondingly arranged below the upper CCD scanning mechanism 7. The conveying device A9 and the conveying device B10 are arranged under the LED controllable light source lighting device 8, and the conveying device A9 and the conveying device B10 can be specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com