Patents

Literature

43 results about "Machine vision image processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

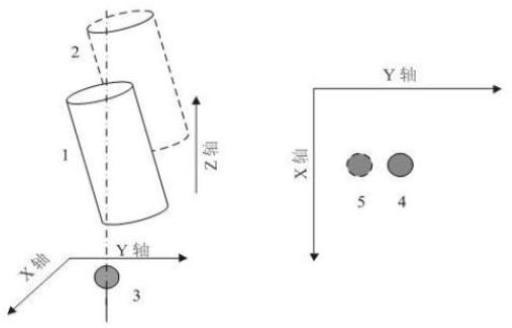

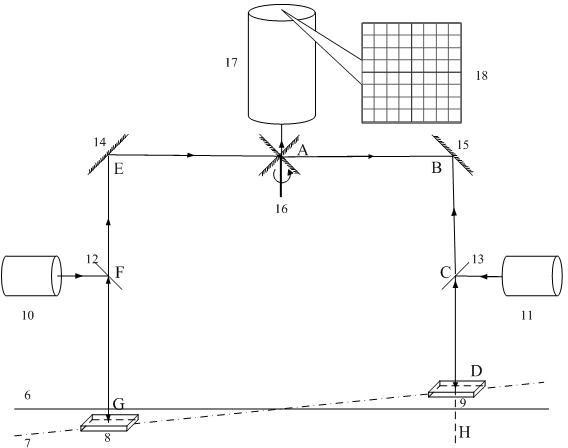

Measurement method for verticality of optical axis of microscope system

InactiveCN102183221AGuaranteed to be verticalHigh measurement accuracyUsing optical meansMotor driveOptical axis

The invention provides a measurement method for the verticality of an optical axis of a microscope system. In the invention, two identical calibrating boards are arranged on an intersecting line of an inclined plane of the optical axis and an optical platform at a distance (L), a light path entering the microscope system is extended to form two arms, a motor drives a microscope lens to move in a direction vertical to the optical platform at a certain step length (S), and images of the two calibrating boards are obtained respectively; and the definitions of the images of the calibrating boards are subjected to quantized judgment by using a computer vision based definition evaluation function (TenenGrad function), and are subjected to normalized comparison, if the definitions of the images of the calibrating boards are within 1% of a judging criterion, the optical axis of the microscope system is judged to be vertical, and the verticality of the optical axis at the moment is calculated, namely h equals to S / L. In the invention, the verticality of the optical axis of the microscope system and the optical platform is measured by using applied optics and machine vision image processing knowledge, so that the optical axis is ensured to be vertical to the platform within an error range. The method has the advantages of high measurement accuracy, simplicity in system and high feasibility.

Owner:TIANJIN UNIV

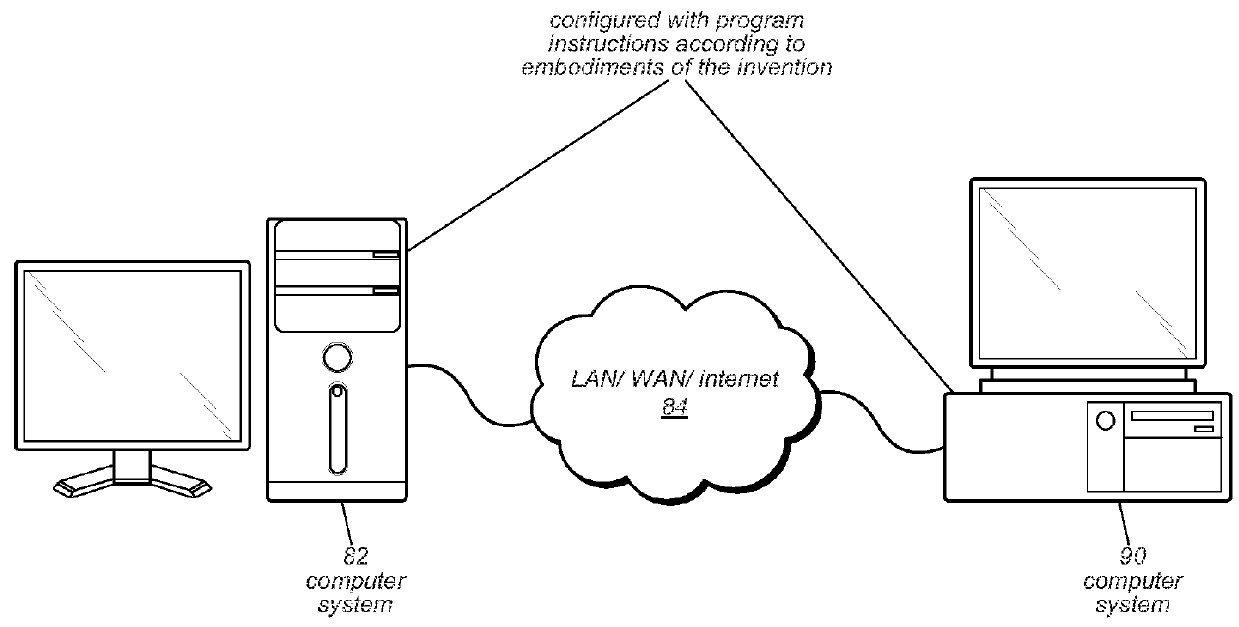

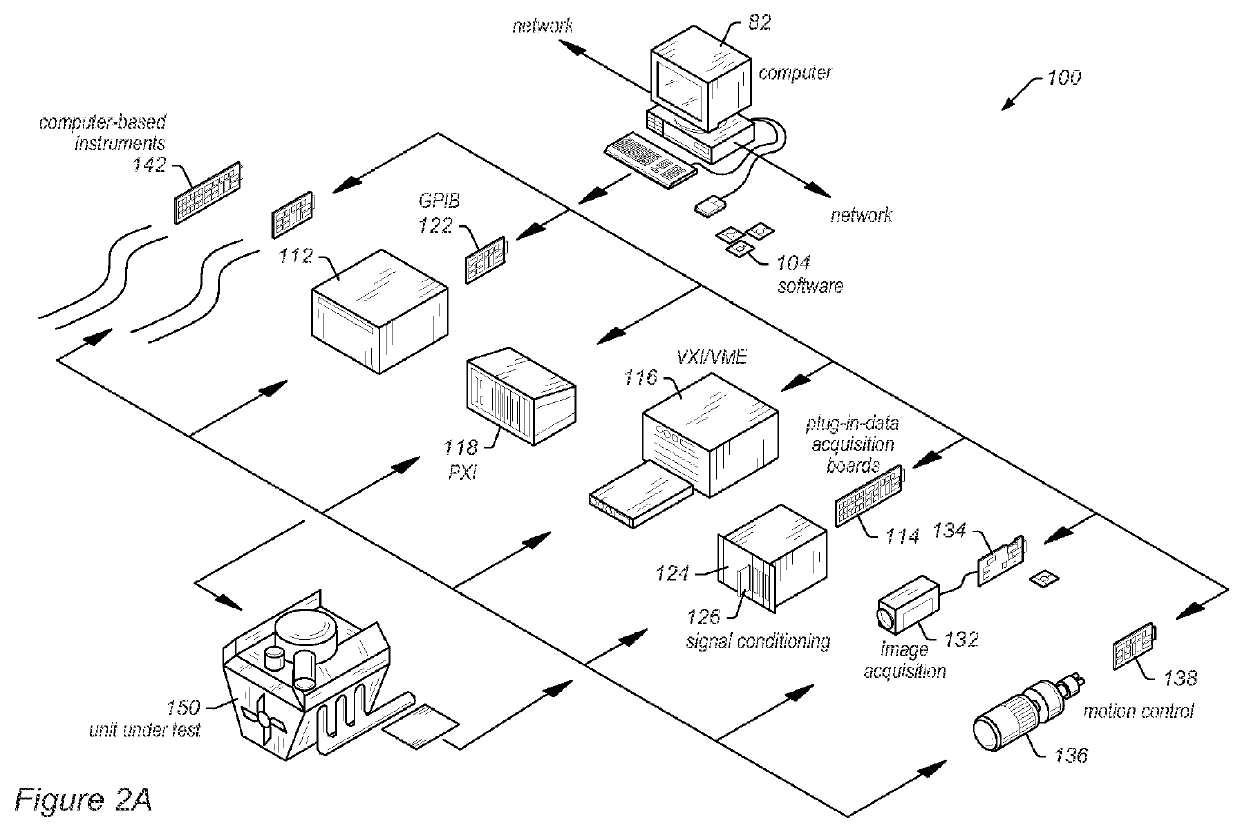

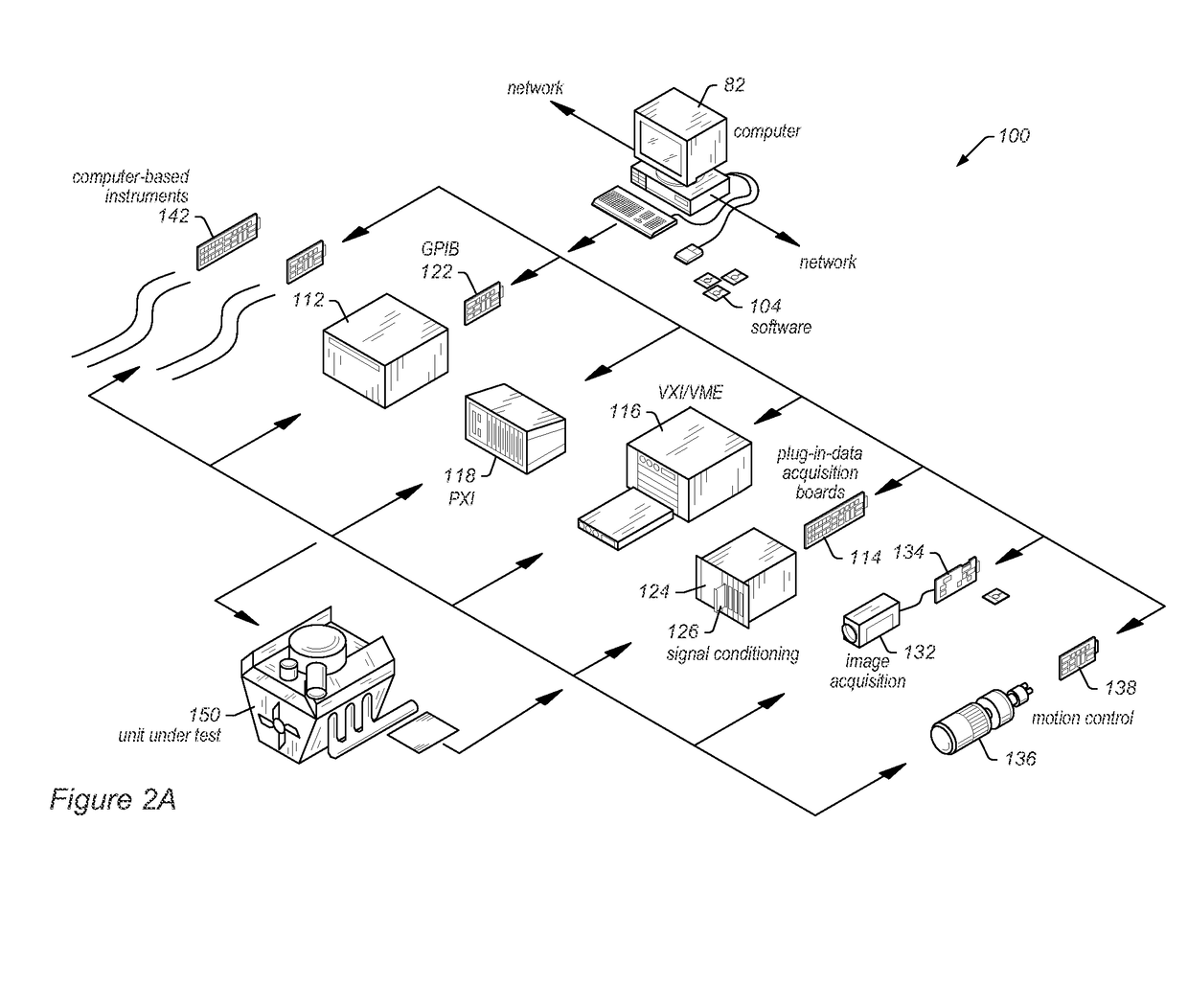

Prototyping an Image Processing Algorithm and Emulating or Simulating Execution on a Hardware Accelerator to Estimate Resource Usage or Performance

ActiveUS20160034617A1Data processing applicationsError detection/correctionGraphicsImaging processing

System and method for creating a machine vision application. A machine vision prototype comprising a plurality of machine vision steps specifying a machine vision image processing algorithm and associated parameters may be stored. The steps may be interpretable by an emulator to perform the specified image processing on an image by emulating or simulating execution of the steps on a hardware accelerator, e.g., a programmable hardware element or graphics processing unit. An emulator may emulate or simulate execution of the steps on the hardware accelerator, thereby generating image processing results, which may be displayed for validation of the emulating or simulating by a user. The prototype may be analyzed, and based on the analyzing, an estimate of resource usage or performance of the image processing algorithm for the hardware accelerator may be determined and displayed, and may be usable for target platform selection or modification of the image processing algorithm.

Owner:NATIONAL INSTRUMENTS

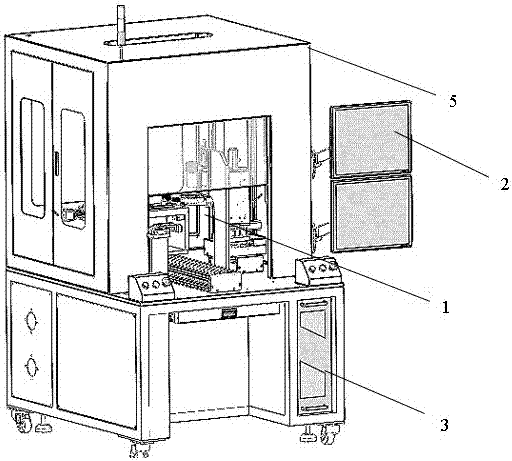

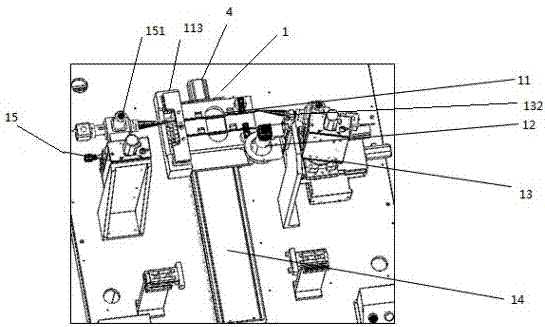

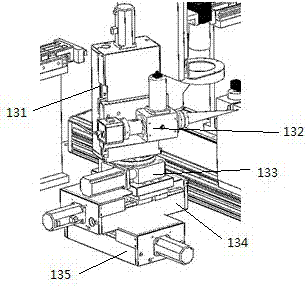

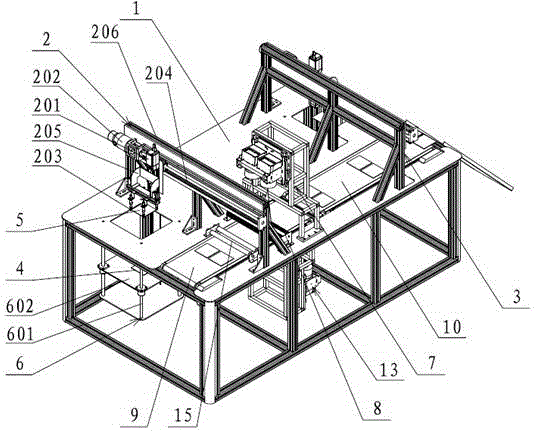

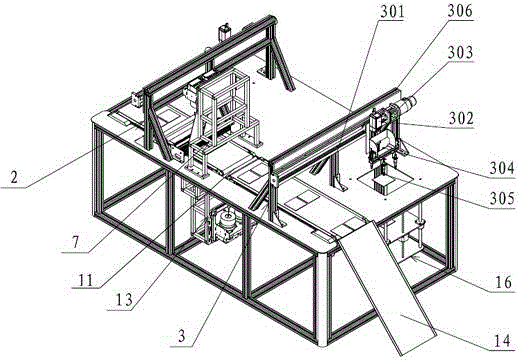

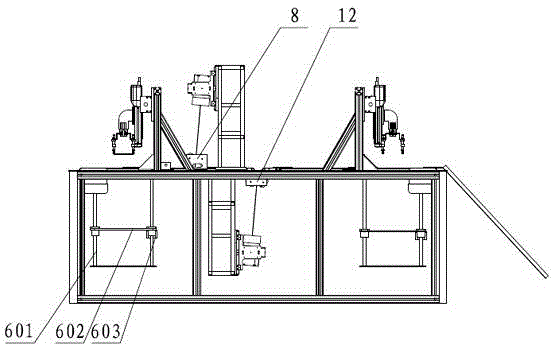

Automatic laser welding device with CCD vision detection function and welding method

ActiveCN107262926AImprove welding precisionImprove accuracyLaser beam welding apparatusImaging processingEngineering

The invention discloses an automatic laser welding device with a CCD vision detection function and a welding method. The device comprises a laser device and a rack cover and further comprises a feeding device provided with a guide rail positioning benchmark, a clamp, a feeding shaft and a rotary pressing air cylinder and horizontally arranged on the laser platform, a two-dimensional laser arranged at one end of the laser platform and provided with a first laser head, a four-dimensional laser arranged at the other end of the laser platform and provided with a second laser head and a CCD vision positioning camera, and a PC controller arranged in the rack cover. The automatic laser welding device has the beneficial effects that the device obtains an image signal of a target through the CCD vision positioning camera, the PC controller calculates a corresponding target position and drives the device to conduct position positioning, the welding precision is improved due to use of machine vision and image processing, tool and product errors are avoided, and influences of human factors on product quality is avoided.

Owner:SHANGHAI WINKELMANN LONGCHUAN (SWL) MOTORCOMPONENTS CO LTD

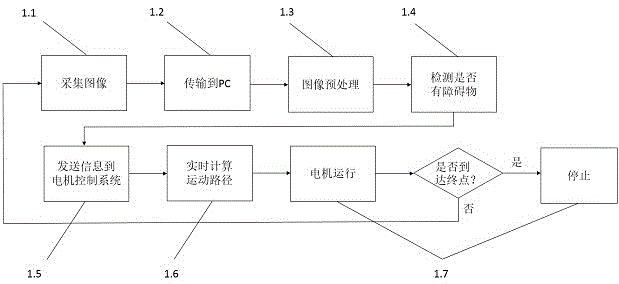

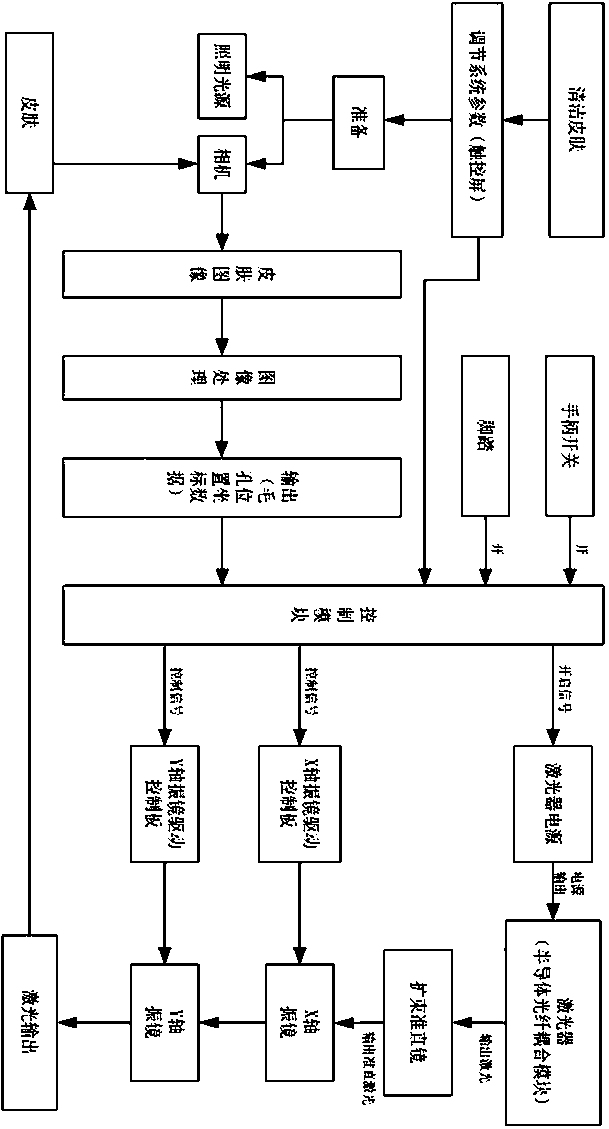

Control method for medical suspension alarm automatic obstacle avoidance based on multi-camera machine vision

InactiveCN105468033AHighlight substantiveSignificant progressControl using feedbackComputer-aided surgeryMulti cameraImage detection

The invention discloses a control method for medical suspension alarm automatic obstacle avoidance based on multi-camera machine vision. The method comprises the steps that (1) image data is collected in real time; (2) the image data is transmitted to a PC; (3) image preprocessing is carried out; (4) whether an obstacle exists is determined through image detection and position information of the obstacle is determined; (5) obstacle information is transmitted to a motor control system of a lower computer; (6) the motor control system analyzes and calculates the obstacle position and plans for and updates a motion route reaching a target position in real time; and (7) the motor control system is operated in order to enable the medical suspension alarm to avoid the obstacle and move to the designated position. The method disclosed by the invention guarantees the automatic obstacle avoidance by using a machine vision image processing theory and a route planning theory and makes use of noise interference brought by a complicated on-site environment of an operating room to images. The control method disclosed by the invention also adopts certain software filtering processing to strengthen overall robustness and accuracy of an algorithm and has the advantages that high-precision identification of the obstacle and accurate obstacle avoidance control of a suspension arm are realized.

Owner:SHANGHAI UNIV +1

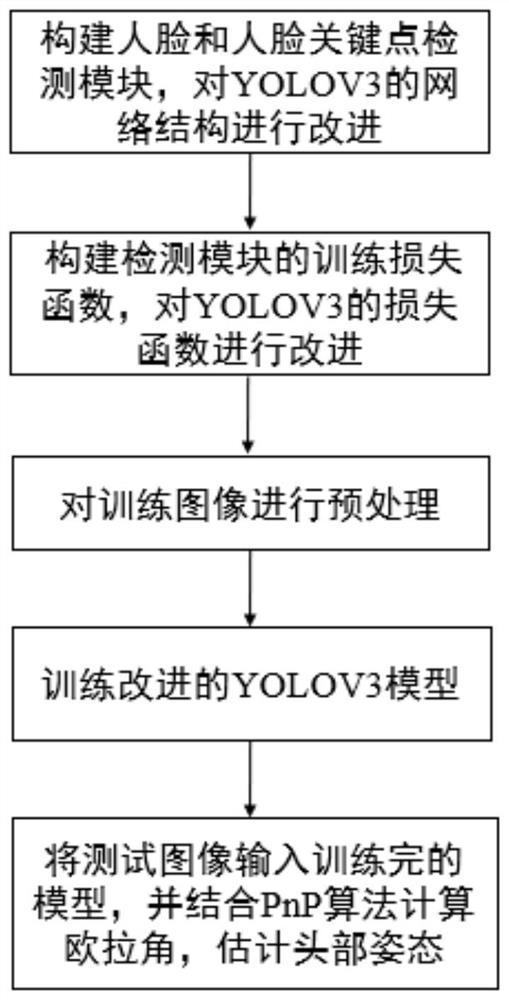

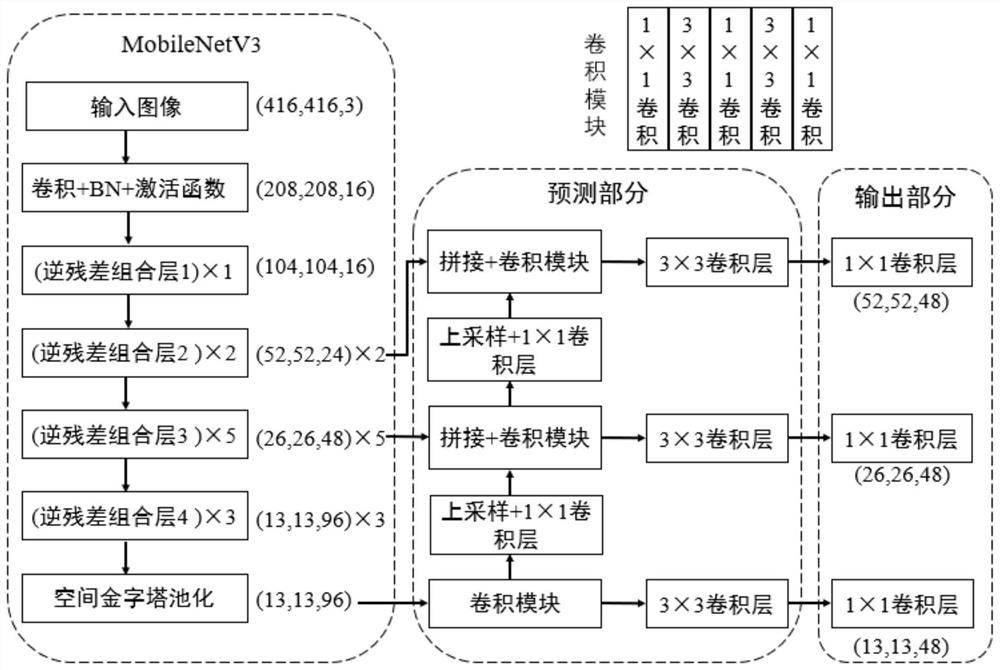

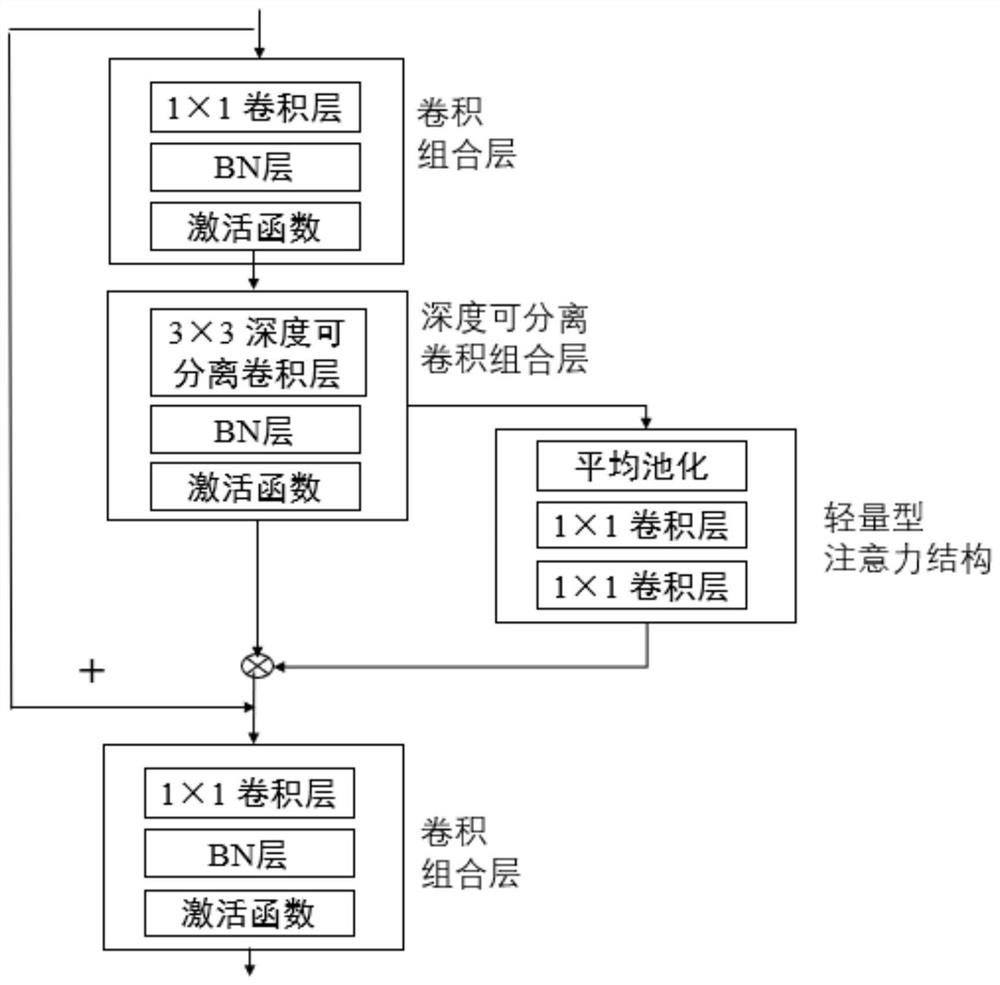

Head posture estimation method combined with YOLO-MobilenetV3 face detection

PendingCN113705521AEasy to handleAccurate estimateCharacter and pattern recognitionNeural architecturesPattern recognitionFace detection

The invention relates to a head posture estimation method combined with YOLO-MobilenetV3 face detection, belonging to the field of machine vision image processing. The method comprises the following steps: constructing a face and face key feature point detection module, improving an original YOLOV3 loss function, preprocessing an image containing a head posture, training an improved YOLOV3 detection model, inputting a test image into the trained model, and calculating an Euler angle and estimating the head posture through combination with a PnP algorithm. The method has the beneficial effects that the MobileNetV3 structure is used for replacing the darknet53 structure in an original YOLOV3 to realize light weight of the model; a spatial pyramid pooling module is adopted to improve the acquisition of global semantics of the image by the model, and the spatial position information of a target is processed more effectively, so detection precision is improved; and a YOLOV3 output layer and the loss function are improved, so the model can detect key points of face, practical application is easy, and the head posture can be estimated more quickly and accurately.

Owner:JILIN UNIV FIRST HOSPITAL

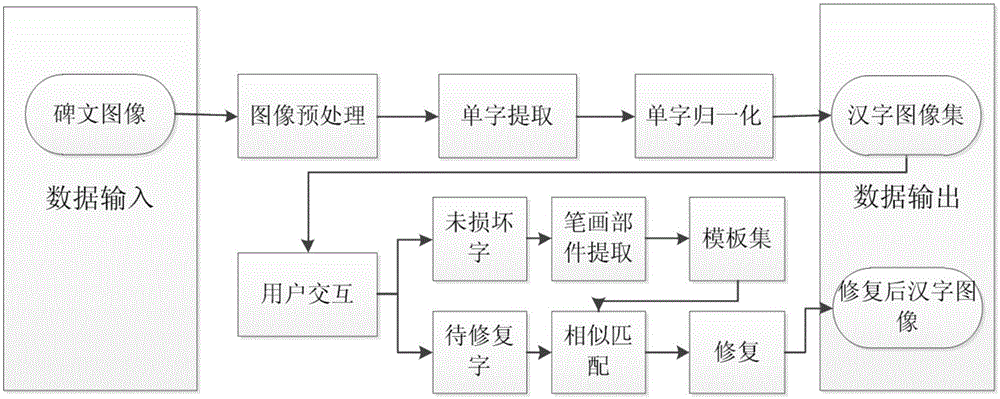

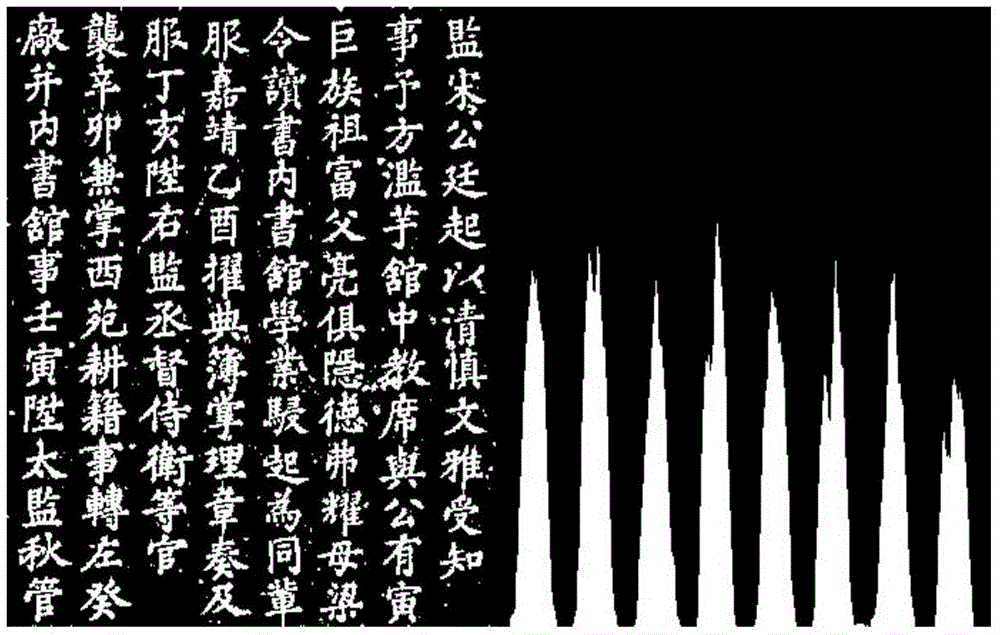

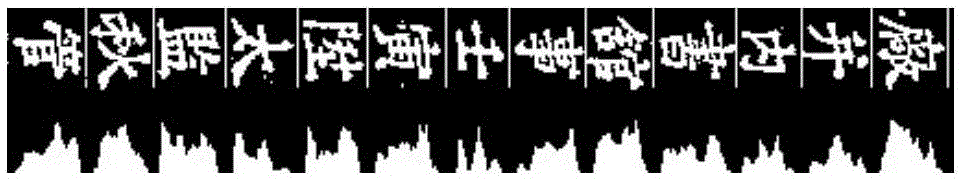

Inscription restoration method based on contour feature description of Chinese character image

The invention provides an inscription restoration method based on the contour feature description of a Chinese character image. The method is applied in the fields of computer virtual reality technology, machine vision, image processing and inscription restoration, wherein the information is limited in a homologous inscription or the calligraphy works of a single writer. During the pre-treatment process, after the inscription is divided into single Chinese characters, the component decomposition and the stroke decomposition are conducted on each extracted single Chinese character. The acquired components and the acquired strokes of Chinese characters together form a component-stroke template set. During the restoration process of damaged Chinese characters, firstly, the structural information and the contour information of the credible component / stroke part of the damaged Chinese characters are extracted. Based on the partial correspondence relationship of the structure matching and contour segments, a template that is highest in similarity is found out of the component-stroke template set to be adopted as a signal source for restoring the damaged part of the damaged Chinese characters. Compared with other image restoration methods, the structural information and the contour detail information of the damaged part of Chinese characters can be restored on the premise that the original style of the inscription is well maintained.

Owner:BEIHANG UNIV

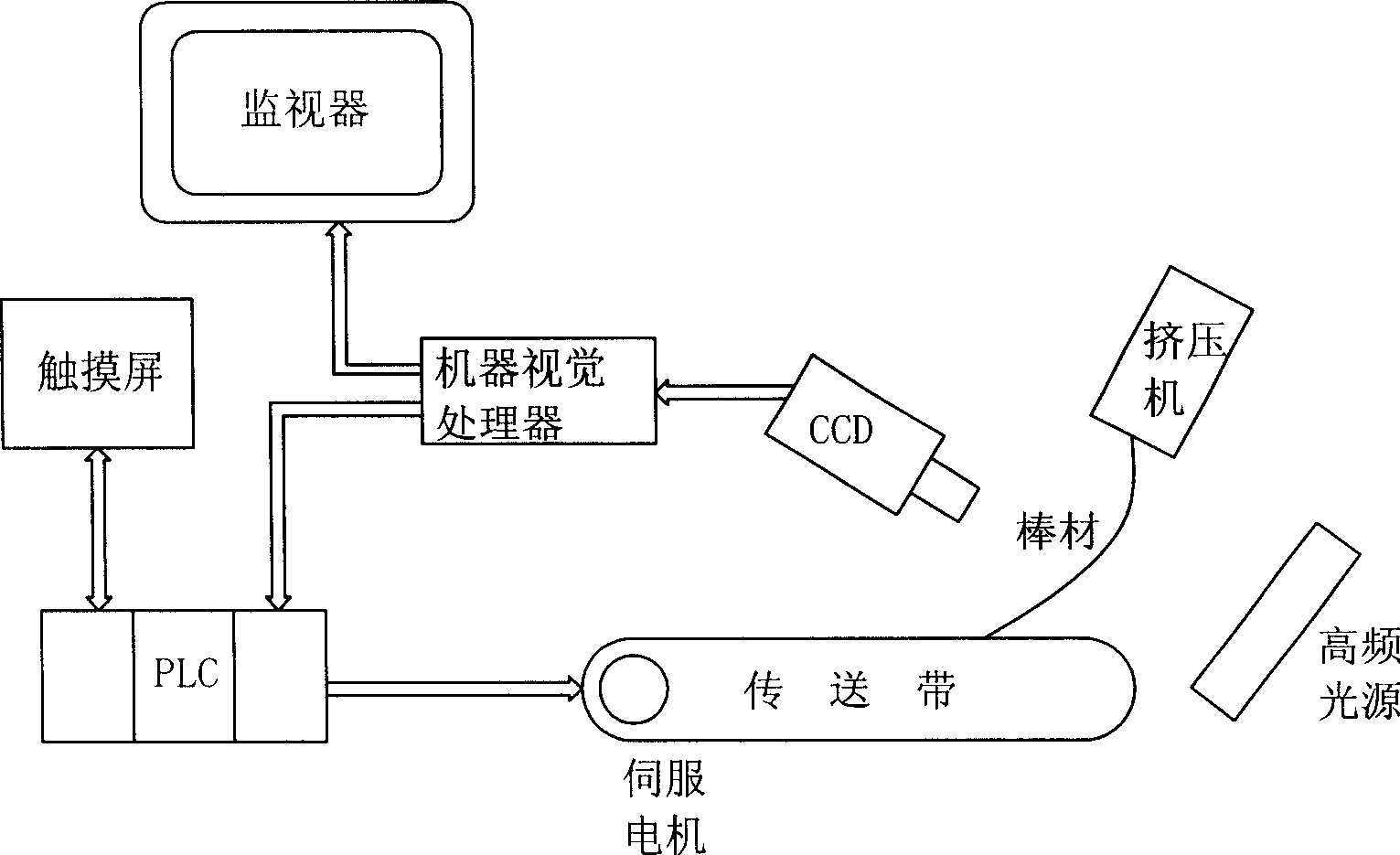

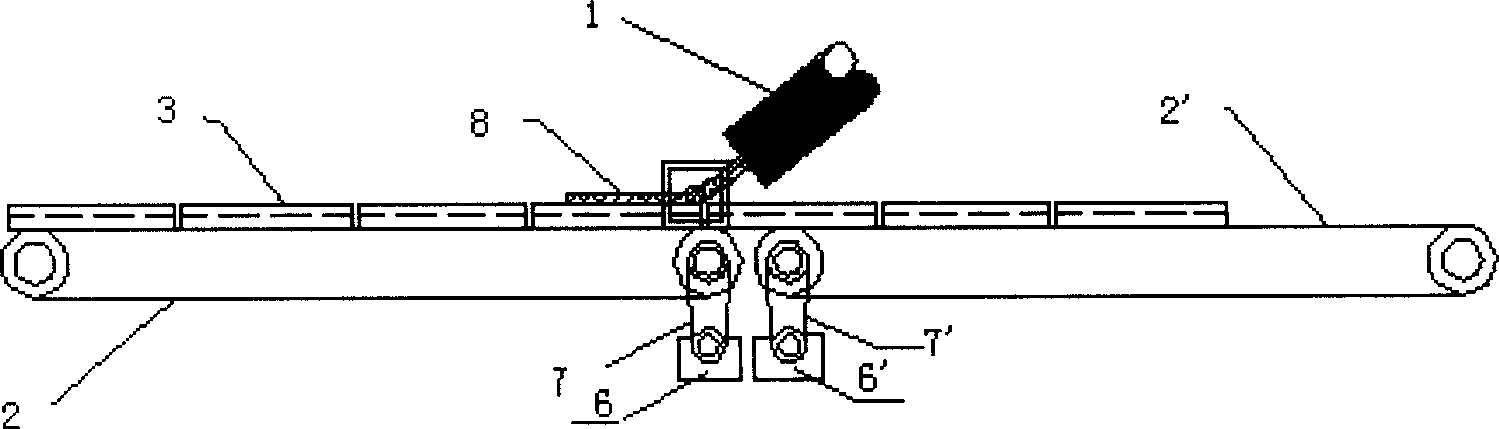

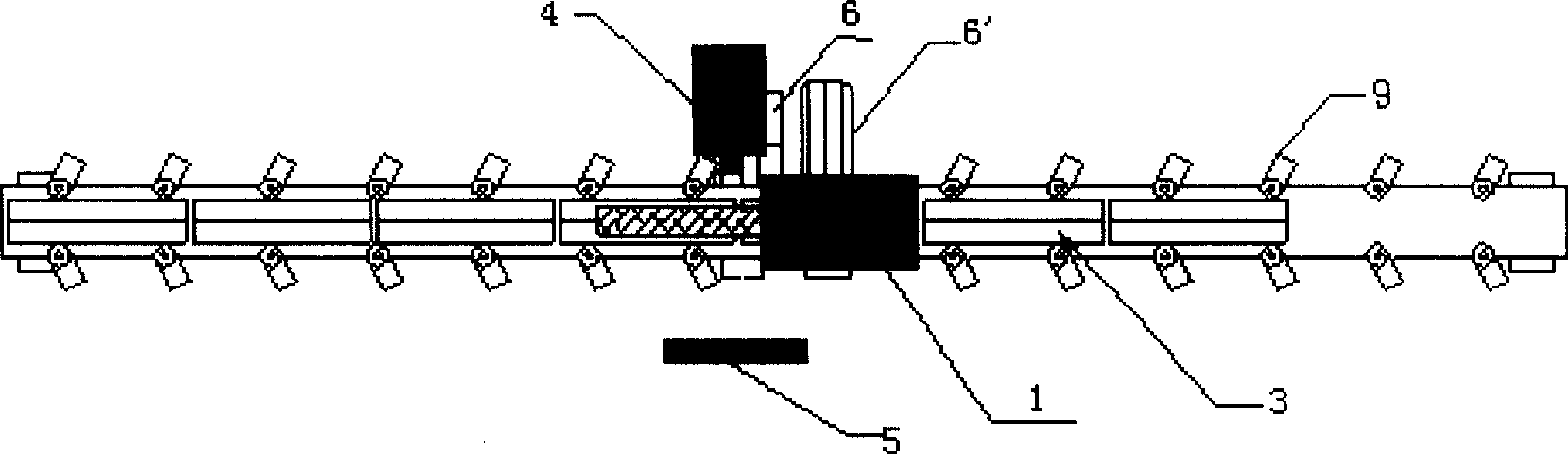

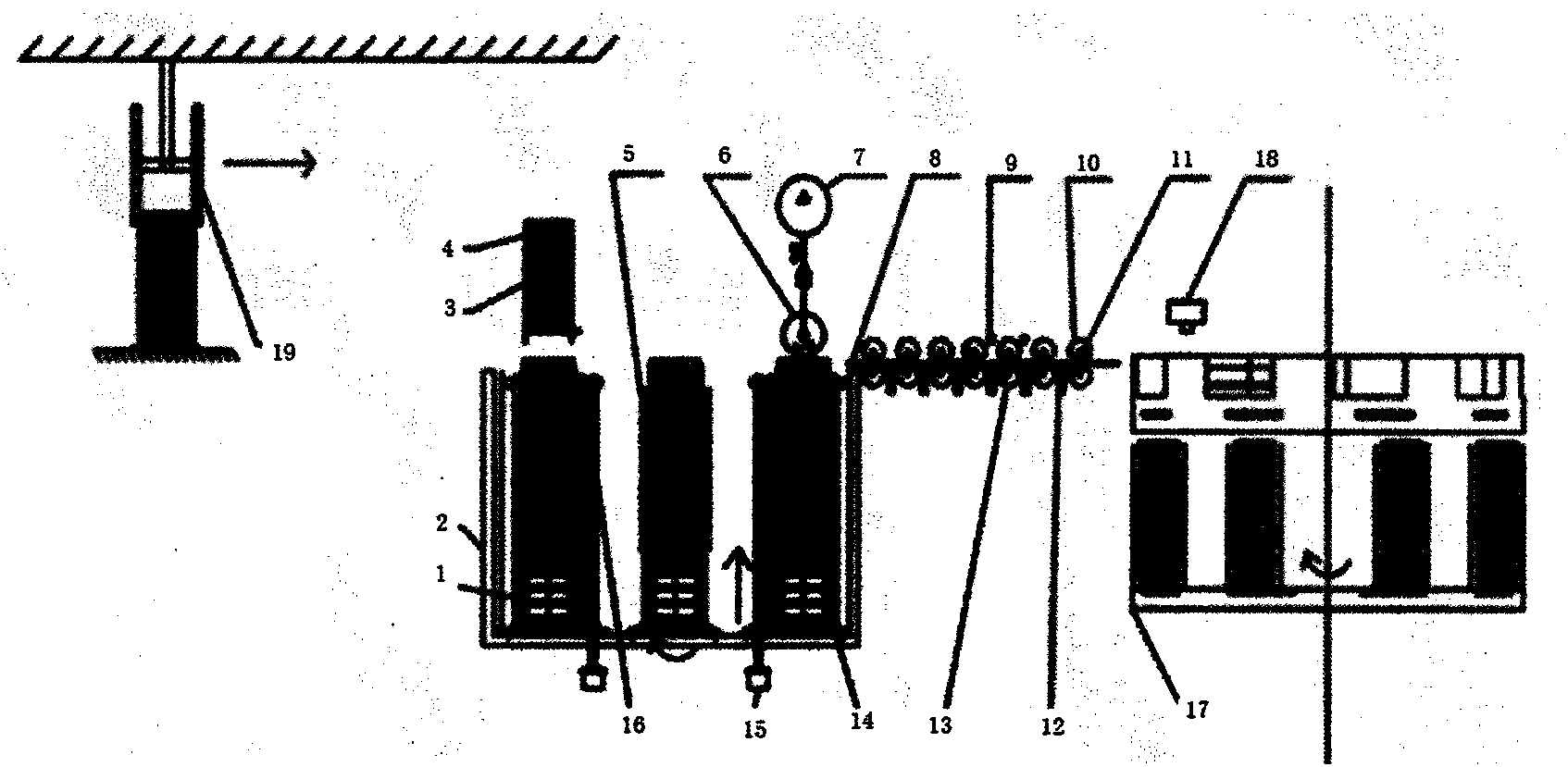

Material-receiving device for squeezing production

ActiveCN101497089AEasy to update and upgradeFlexible programmingExtrusion control devicesCeramic shaping apparatusEngineeringCcd camera

The invention discloses an extrusion production material receiving device, which comprises a CCD camera, a high frequency light source, a machine visual image processor, a PLC host computer, a servo motor, two horizontal conveying belts and a plurality of boats, wherein the CCD camera takes photos of extruded bar stock of an extrusion head of an extruder one by one; the high frequency light source provides background light for the CCD camera; the machine visual image processor receives photos shot by the CCD camera and carries out digitalized treatment on the photos; the PLC host computer receives data transmitted by the machine visual image processor through a serial bus, analyzes, judges and extrudes forms of products, and sends a speed regulation control command; the servo motor acts according to the command received by the PLC host computer; one horizontal conveying belt is synchronously driven by the servo motor; the other horizontal conveying belt is driven by a DC motor and transmits the boats to the horizontal conveying belt; and the plurality of the boats are positioned between a plurality of pairs of limit stop blocks on both sides of two horizontal conveying belts with a same axle line, move forward and are provided with V-shaped material receiving grooves. The extrusion production material receiving device is suitable for producing extruded products with small diameter or other small specifications and dimensions on a large scale and can ensure internal and external quality of the products.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Texture-free plane structure industrial part identification and 6D pose estimation method based on template matching

ActiveCN113034600ASolve the problems of traditional teach-online methodImprove matching speedImage enhancementImage analysisTemplate matchingImaging processing

The invention belongs to the technical field of machine vision and image processing, particularly relates to a texture-free plane structure industrial part identification and 6D pose estimation method based on template matching. Aiming at the problems that an existing mode is small in application range and low in flexibility degree and feeding and discharging of disorderly stacked workpieces cannot be realized, the following scheme is provided. The method comprises the following steps: firstly, acquiring RGB images and depth maps of stacked workpieces through an RGB-D camera, and performing workpiece identification classification and 2D image positioning on the RGB images based on 2D template matching; converting the depth maps into 3D point cloud, carrying out filtering processing on a point cloud image to remove background point cloud and noise point cloud interference, and carrying out Euclidean clustering segmentation on the filtered point cloud to obtain single workpiece instance point cloud; and performing RANSAC plane fitting on the point cloud of a single part, and estimating the 6D pose of an object in a camera coordinate system by using a parameter equation of a fitting plane and the 2D image pixel coordinates of the center of the workpieces.

Owner:SHANGHAI JIAO TONG UNIV

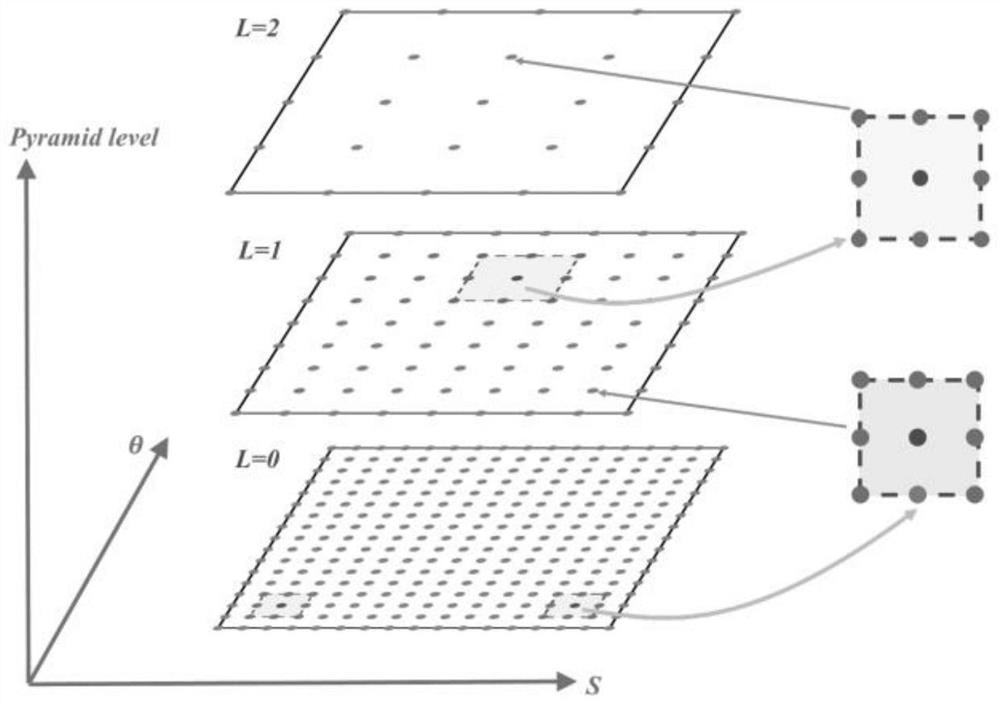

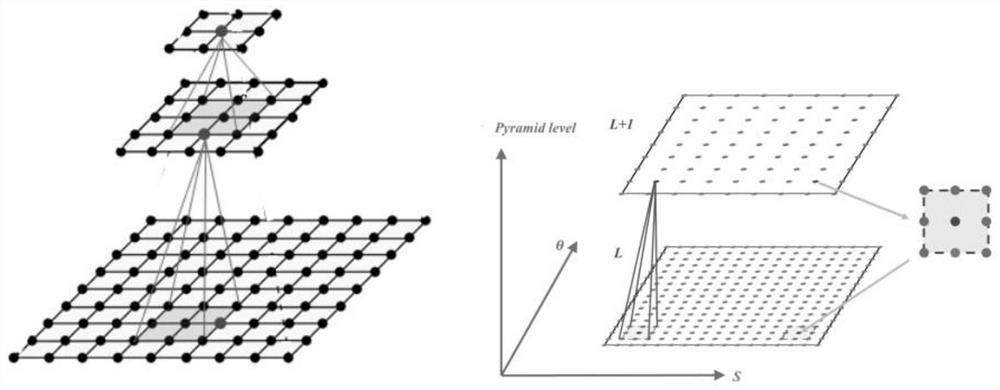

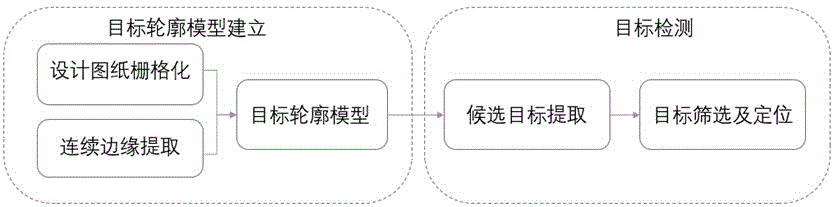

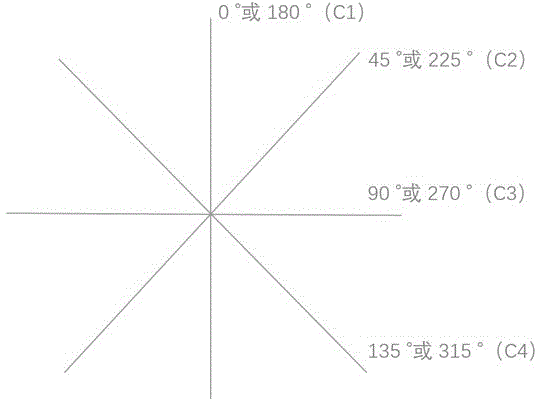

Planar object detection method based on continuous edge characteristic

ActiveCN106022337ASolve the problem of insufficient versatilityMeet the needs of real-time detectionCharacter and pattern recognitionObject basedVisual perception

The invention relates to a planar object detection method based on a continuous edge characteristic, and belongs to the technical field of machine vision image processing. The method comprises the steps including extracting the continuous edge characteristic, establishing a target contour model, extracting candidate objects based on a Hough transformation idea, screening the candidate objects and realizing accurate positioning. The method is suitable for an industrial scene, and can be used to establish a model of an unknown planar object rapidly and realize object detection. The method needs not to be adjusted for the specific object, and is suitable for different planar objects (as well as objects whose surfaces are planar), and the problem that the university of a present visual system is low is solved to certain extent. The detection precision is higher, the processing speed is high, and certain anti-noise capability is provided.

Owner:FUDAN UNIV

Intelligent composite material net piece sorting machine

The invention relates to an intelligent composite material net piece sorting machine which is characterized by comprising a blanking cylinder with a cover, an overturning mechanical feeding subsystem, a multi-station rotary table discharge subsystem, a multi-position intelligent detection and roller conveying subsystem, an image processing and sorting subsystem and an intelligent quality analysis and decision support subsystem, wherein composite material net pieces are arranged inside the blanking cylinder in an up-down stacked manner; the blanking cylinder with the composite material net pieces is sealed by a cover; the multi-position intelligent detection and roller conveying subsystem is used for discharging the composite material net pieces to a feeding position of the image processing and sorting subsystem sequentially. The machine is a machine vision image processing-based intelligent laminated net piece sorting machine, manual net piece detection and sorting can be replaced by machine vision, rapid and accurate net piece sorting is achieved, the production efficiency is improved, and the delivery quality of finished products is ensured.

Owner:DONGHUA UNIV

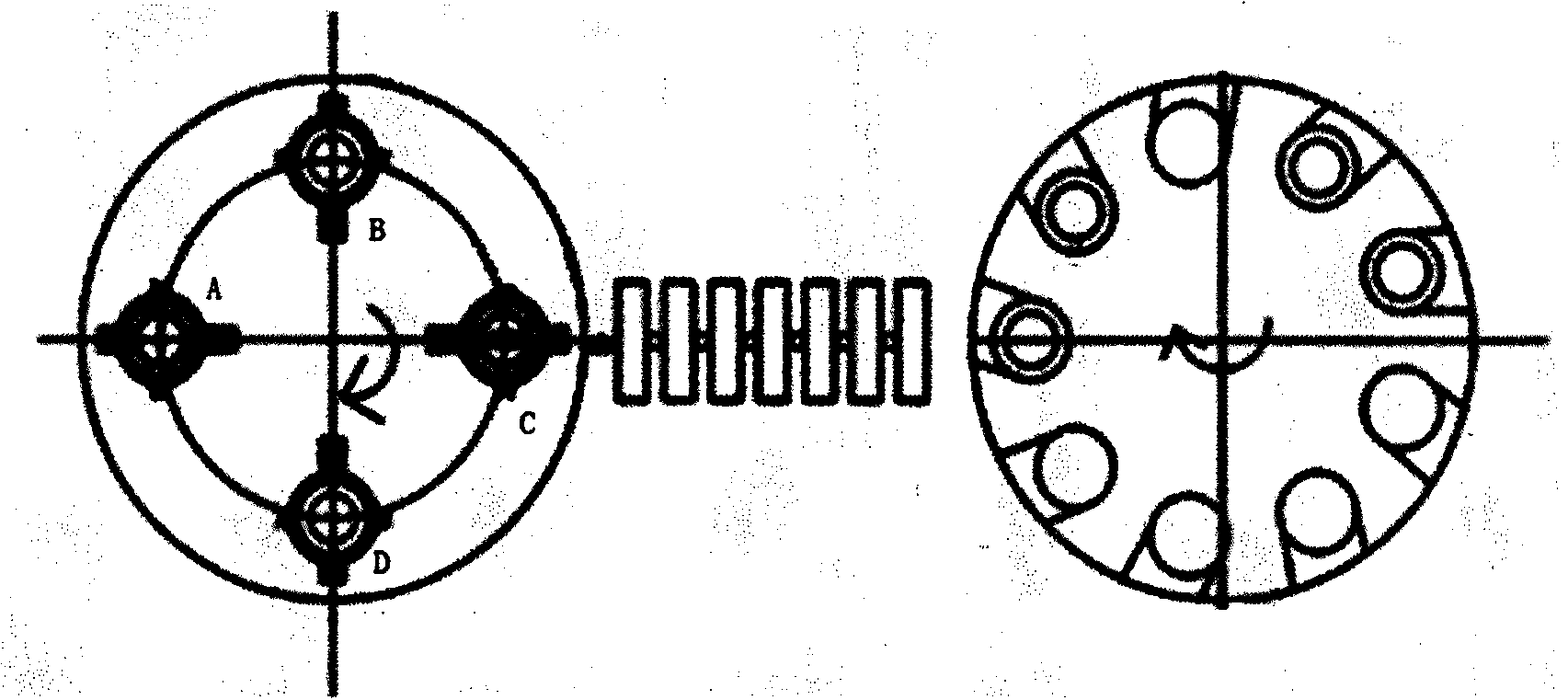

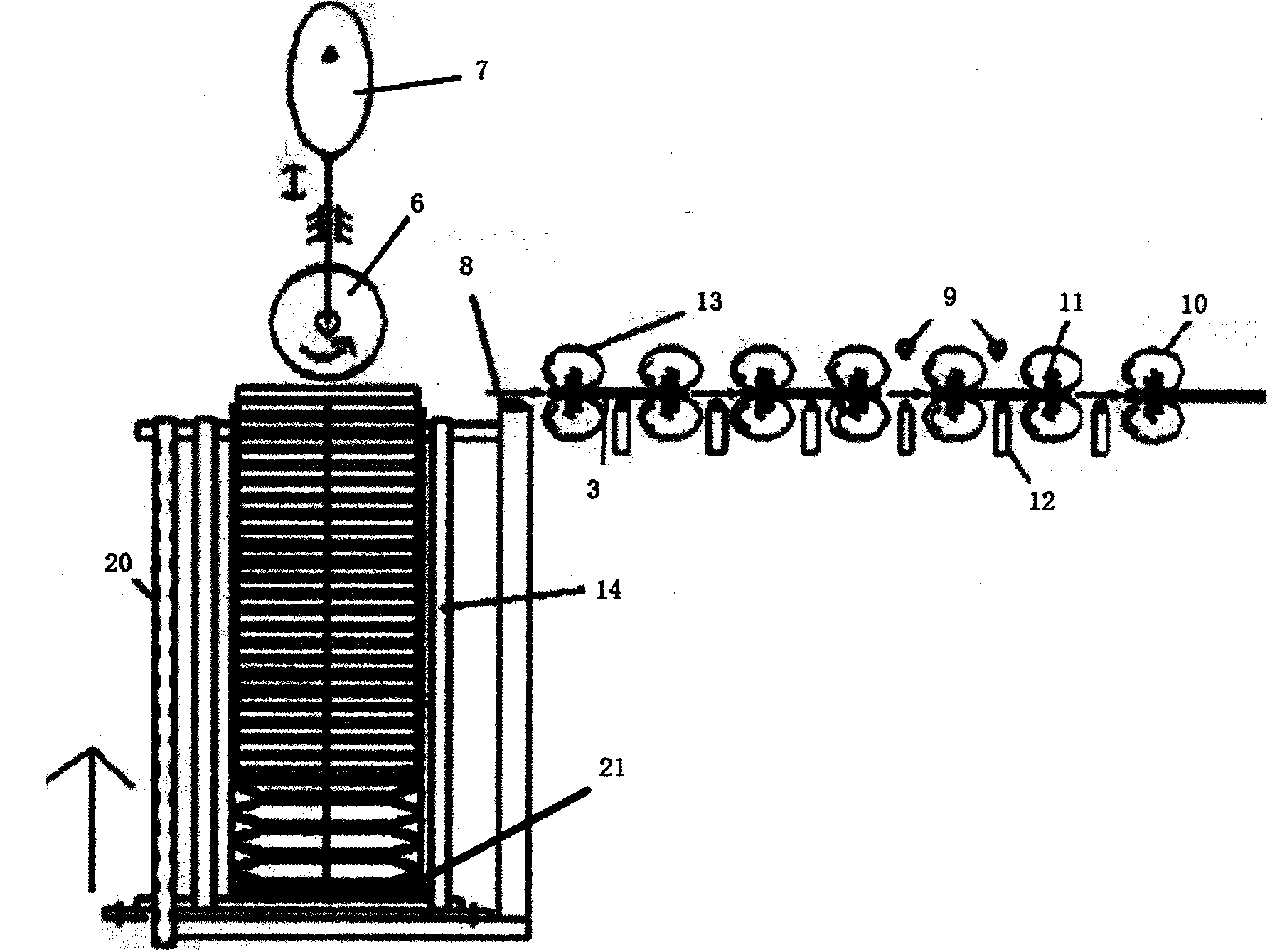

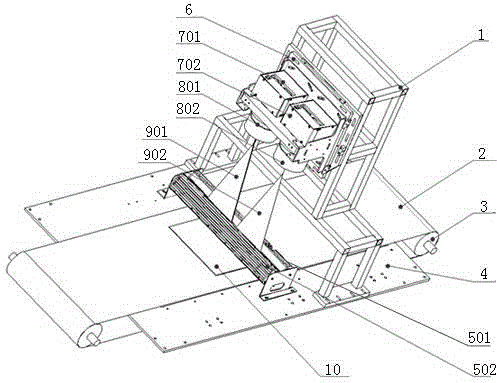

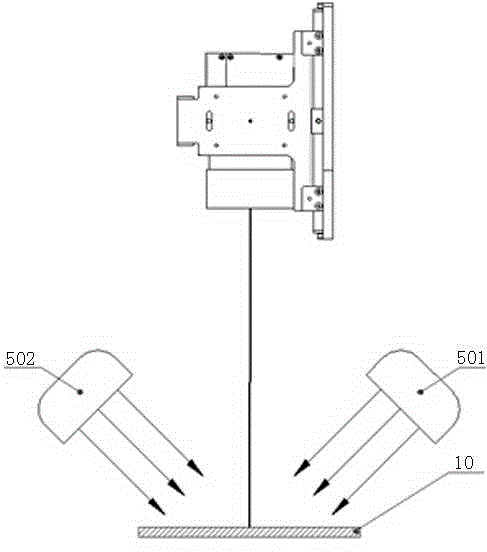

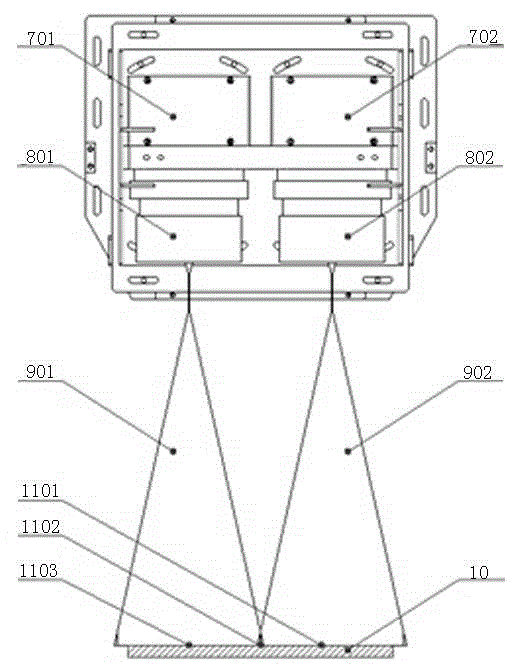

Horizontal CCD (charge-coupled device) two-sided line scanning system

InactiveCN104897678APromote increaseReduce false positivesMaterial analysis by optical meansEngineeringMechanical engineering

The invention relates to a horizontal CCD (charge-coupled device) two-sided line scanning system, and belongs to the technical field of machine vision image processing. The system comprises a horizontal scanning system support. The both ends of the horizontal scanning system support are provided with an extracting mechanism and a discharging mechanism; an upper CCD scanning mechanism is disposed between the extracting mechanism and the discharging mechanism; a first LED (light-emitting diode) controllable illuminant lighting device is disposed below the upper CCD scanning mechanism; a conveying device A and a conveying device B are disposed below the first LED controllable illuminant lighting device; a scanning opening is disposed between the conveying device A and the conveying device B; a second LED controllable illuminant lighting device is disposed below the scanning opening, and a lower CCD scanning mechanism is disposed below the second LED controllable illuminant lighting device. By using horizontal way to perform two-sided scanning, the system can scan multiple items side by side at one time; the items can be allowed to roll and continuously transport and a next plate can enter into the scanning area without waiting for the completion of one transport period, and therefore, production efficiency is greatly improved.

Owner:HANGZHOU POWER TECH CO LTD

Prototyping an image processing algorithm and emulating or simulating execution on a hardware accelerator to estimate resource usage or performance

System and method for creating a machine vision application. A machine vision prototype comprising a plurality of machine vision steps specifying a machine vision image processing algorithm and associated parameters may be stored. The steps may be interpretable by an emulator to perform the specified image processing on an image by emulating or simulating execution of the steps on a hardware accelerator, e.g., a programmable hardware element or graphics processing unit. An emulator may emulate or simulate execution of the steps on the hardware accelerator, thereby generating image processing results, which may be displayed for validation of the emulating or simulating by a user. The prototype may be analyzed, and based on the analyzing, an estimate of resource usage or performance of the image processing algorithm for the hardware accelerator may be determined and displayed, and may be usable for target platform selection or modification of the image processing algorithm.

Owner:NATIONAL INSTRUMENTS

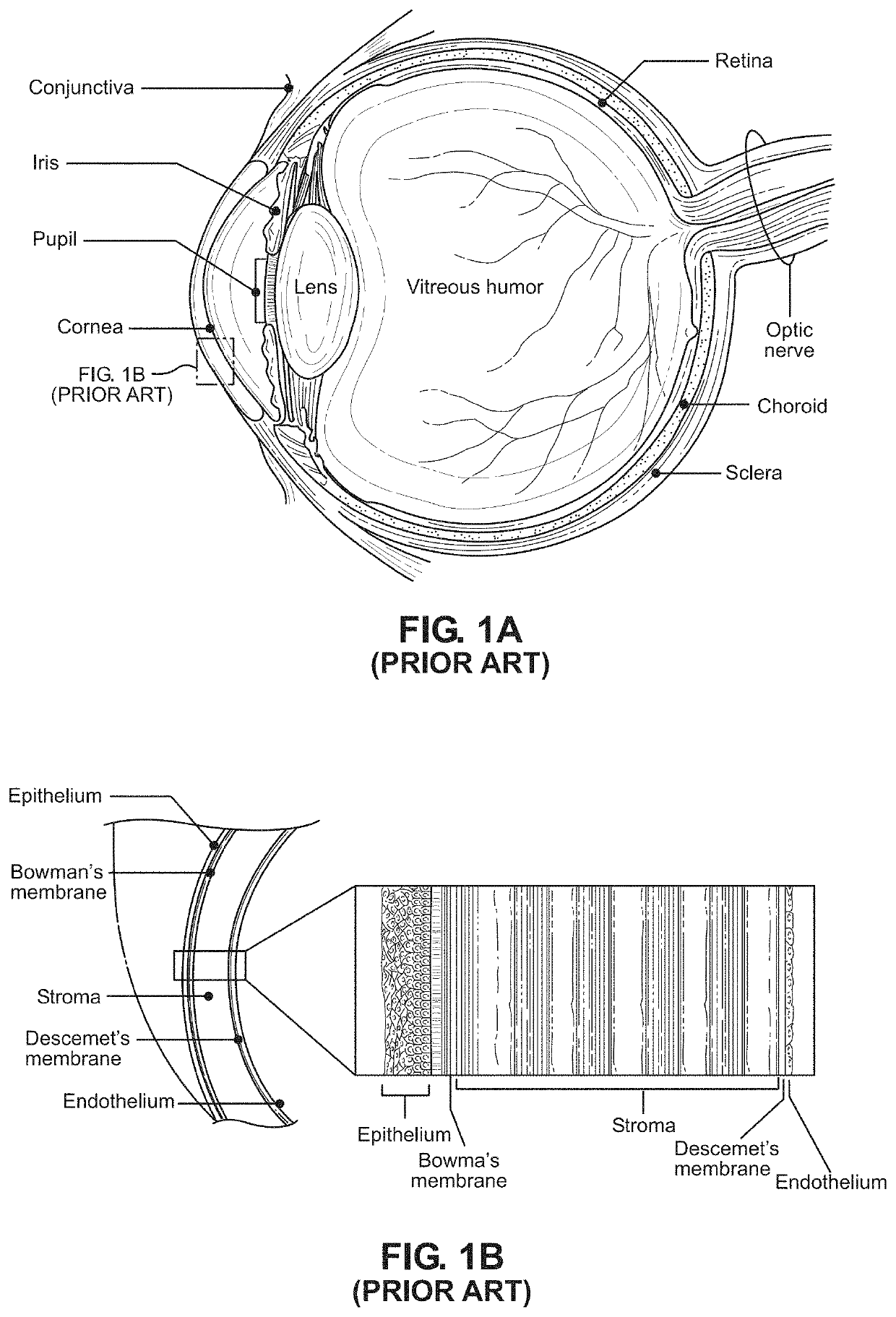

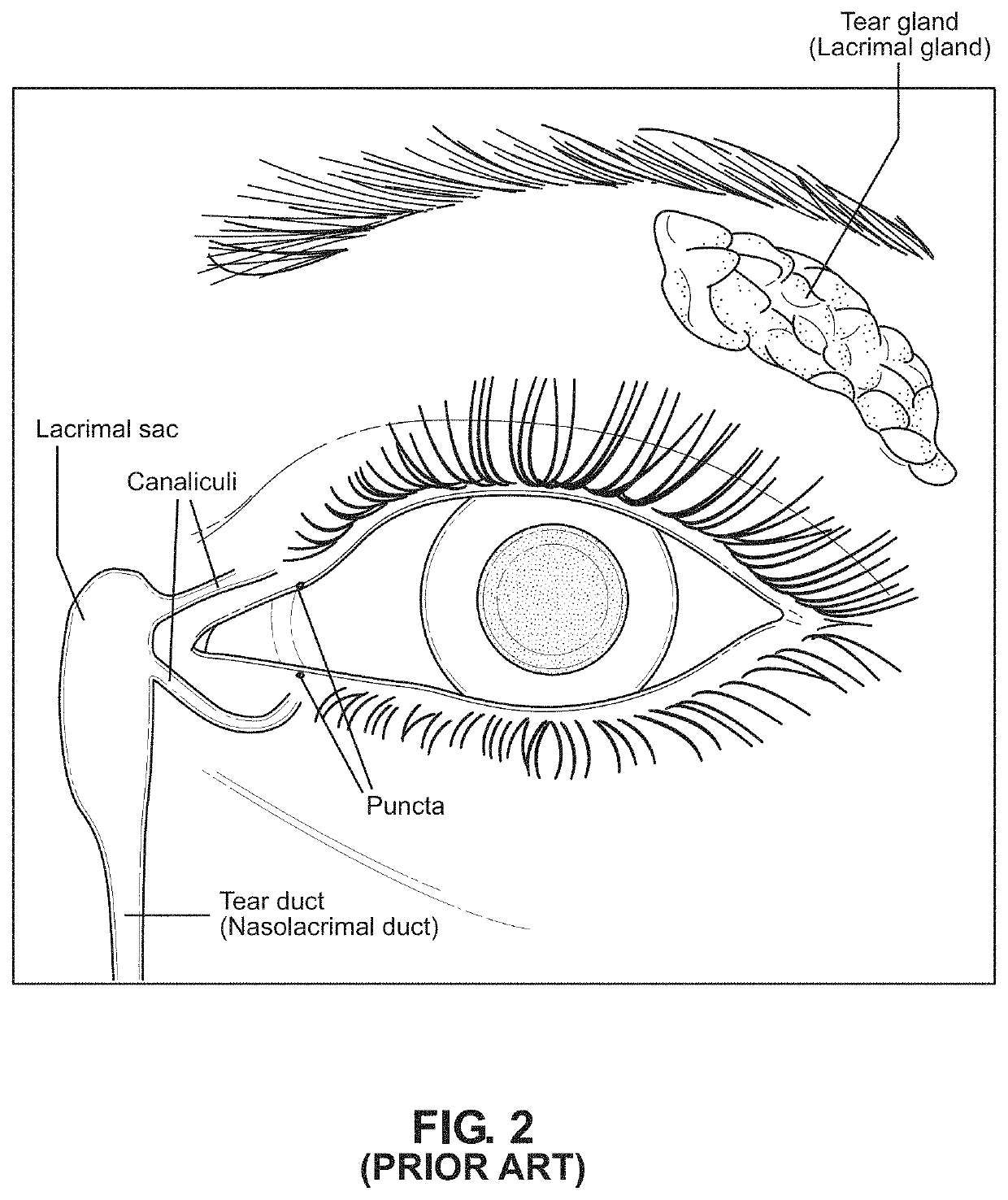

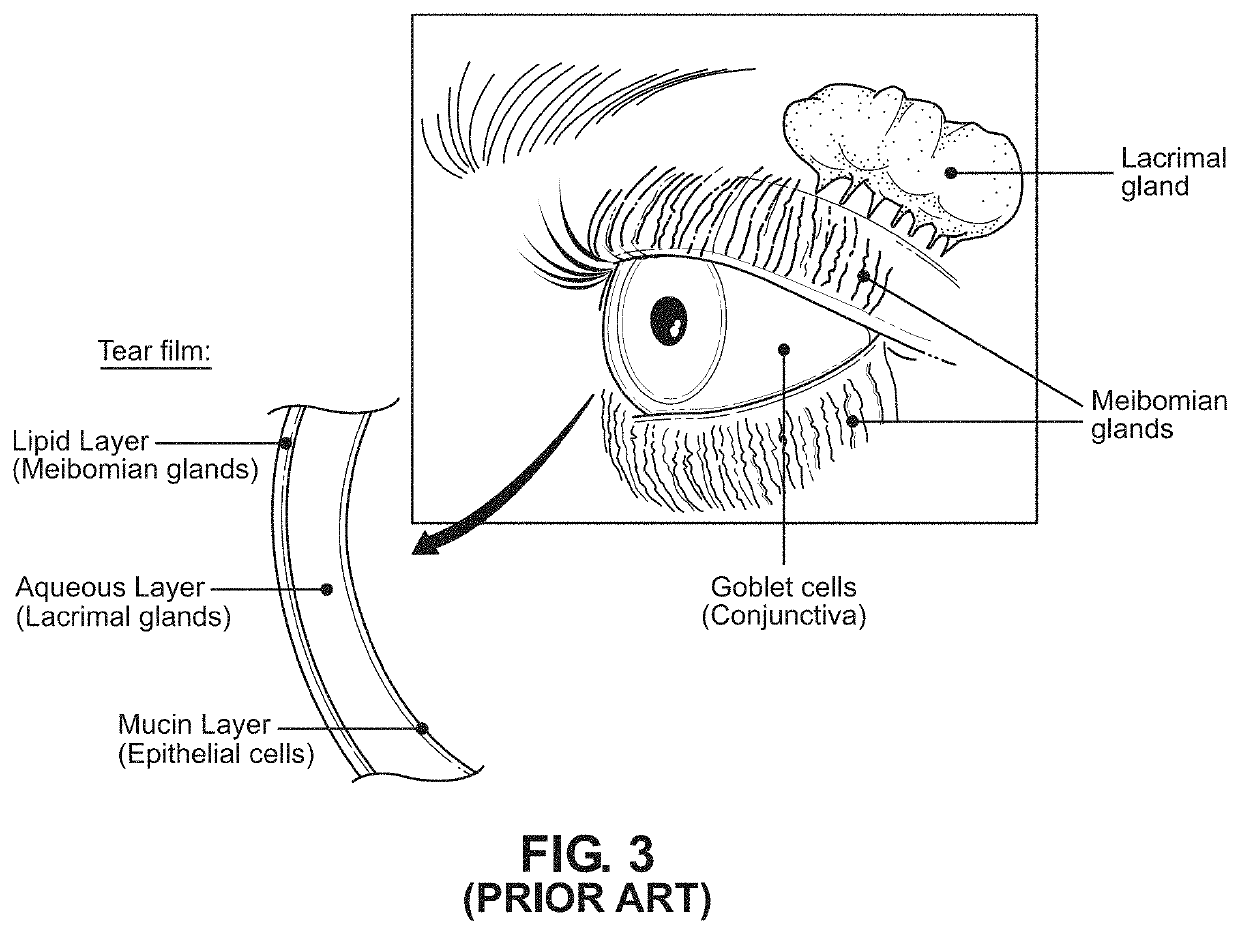

Method of and system for automated machine-assisted detection of ocular disease conditions in human eyes captured using visible illumination light sources and digital camera systems

PendingUS20220313077A1Reliable and reliableMedical imagingDiagnostic recording/measuringDigital imagingOcular surface

Digital imaging processing system and methods for automatically recognizing ocular diseases including dry eye disease, and other ocular conditions in the eyes of humans by automatically (i) processing 2D in vivo digital images of the human eyes formed, captured and detected using a visible-wavelength operating digital camera system, and (ii) using machine-vision image processing subsystems (e.g. engines) to automatically detect the presence and location of specific objects in the ocular surfaces in the human eye, and confirm that specific conditions have been satisfied during image processing to support automated recognition of a specific ocular disease and other ocular conditions indicative of ocular pathology.

Owner:CORNEACARE INC

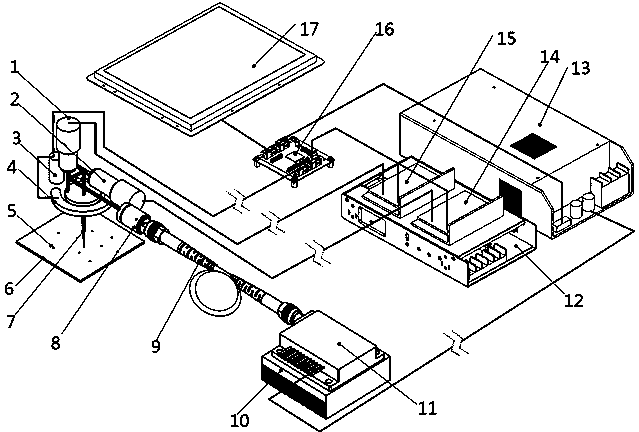

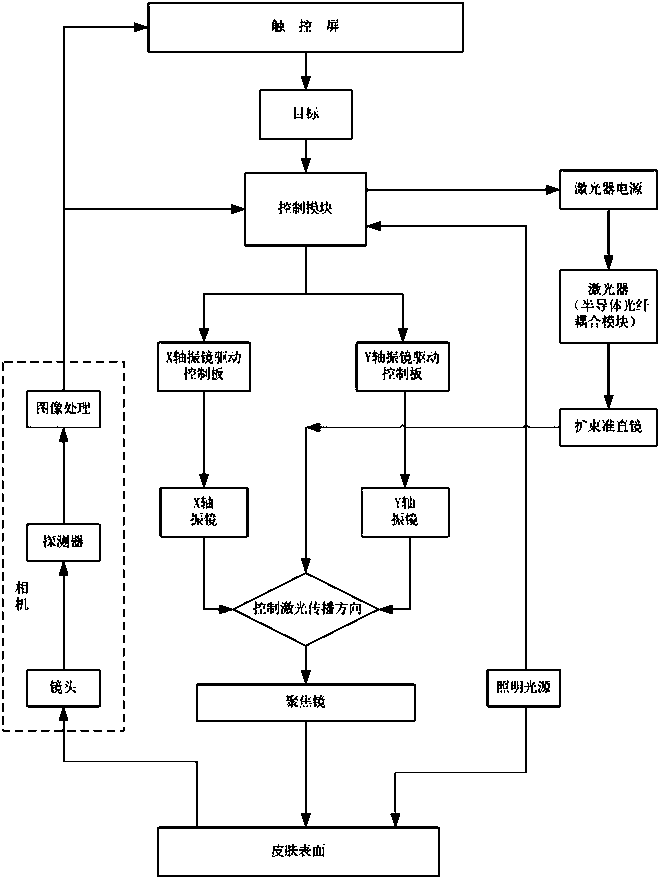

Skin pore recognition and positioning depilation system based on computer vision

InactiveCN110840559AReduced Power RequirementsAdjustable areaSurgical instrument detailsMedical equipmentOphthalmologyMachine vision image processing

The invention relates to the field of cosmetic medicine, in particular to a skin pore recognition and positioning depilation system based on computer vision, comprising a main unit system and a treatment handle; the main unit system comprises a display system, a control system and a power supply system; the treatment handle comprises a semiconductor laser coupling module, a collimation system, anXY scanning galvanometer, a focusing lens, a camera image processing module and an illumination light source; the machine vision image-processing technology is applied to the field of semiconductor laser depilation, the traditional high-power semiconductor laser depilation is broken through, and depilation is carried out by means of the low-power semiconductor laser fiber coupling module; after animage is collected by a camera, sending the image to a PC (personal computer) for image processing is not required; after the image is collected by the camera, digital image processing is carried outthrough hardware (FPGA, DSP, and DSP+FPGA), pore position data are directly output; the machine vision intelligent identification technology is integrated, and targeted treatment can be carried out on skin, so that the power requirement of a laser is greatly lowered; the area of a treatment region is adjustable, so that the loading degree of the whole machine system is greatly reduced.

Owner:广州三土医疗科技有限公司

Bobbin yarn appearance defect classification method based on a deep convolutional neural network

ActiveCN109871906ATo achieve the function of pattern recognitionImprove reliabilityCharacter and pattern recognitionNeural learning methodsYarnAlgorithm

The invention discloses a bobbin yarn appearance defect classification method based on a deep convolutional neural network. The bobbin yarn appearance defect classification method comprises the following steps of S1, carrying out image cutting; S2, carrying out manual sorting; S3, cleaning the data; S4, reorganizing the data; S5, carrying out data augmentation; S6, carrying out a neural network structure; S7, carrying out performing model training; S8, adjusting parameters; S9, carrying out model testing; and S10, after obtaining the optimal data, starting from the step S3 until the loss valueof the verification set approaches 0 and cannot be reduced, and finally obtaining an optimal model. Compared with a traditional machine vision image processing method, the glass fiber bobbin yarn appearance detection method based on the convolutional neural network has the advantages that mathematical fitting is carried out on surface layer characteristic data extracted from a picture; and finally, a satisfactory result can be achieved by using a simple classifier, so that the reliability and the detection speed are improved, and the labor cost is reduced.

Owner:XIAN HUODE IMAGE TECH CO LTD

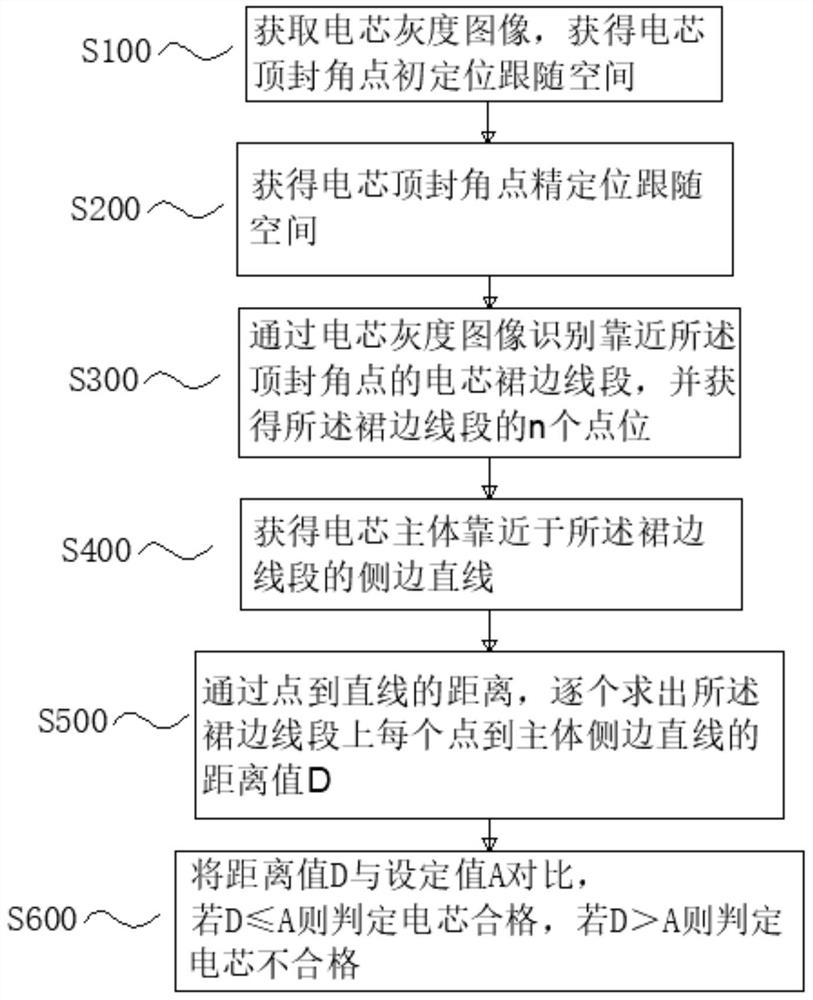

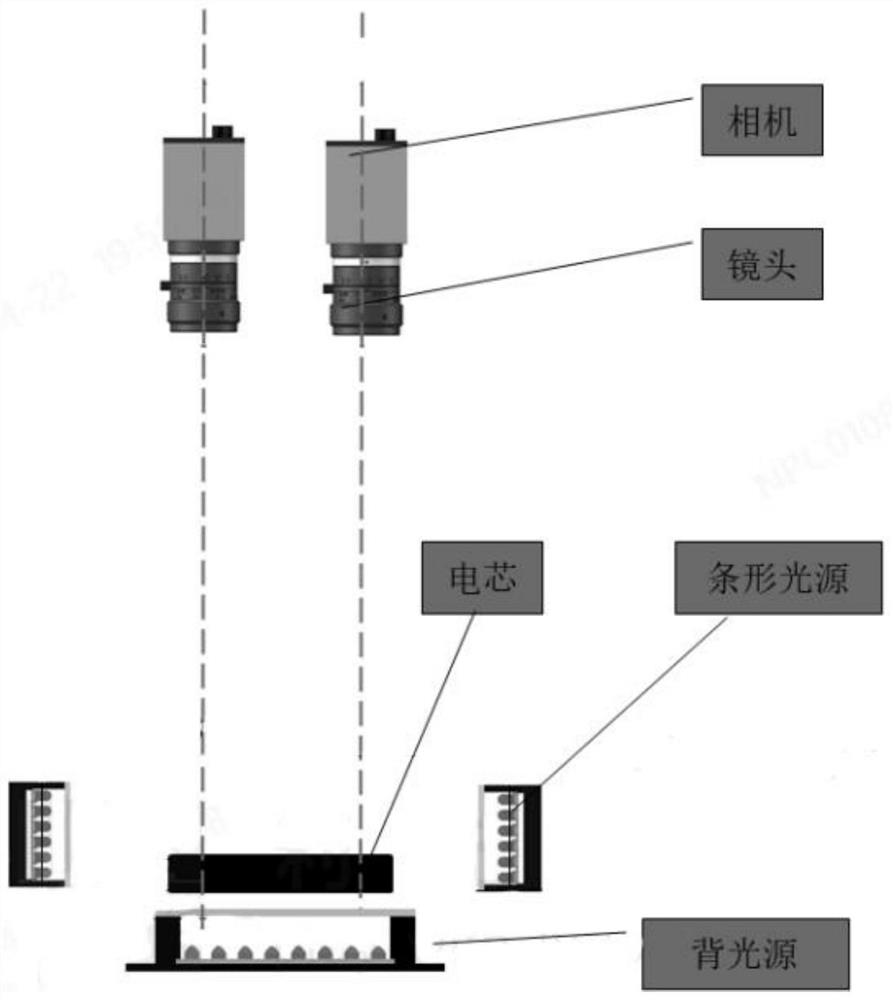

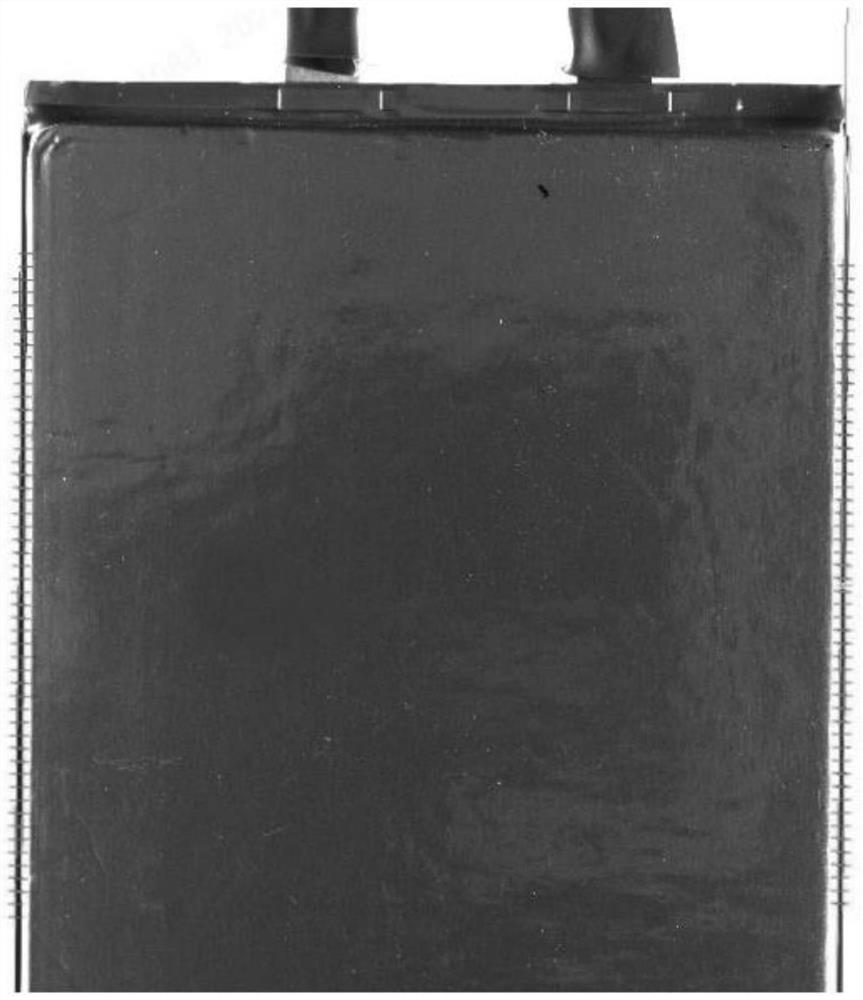

Battery cell skirt edge cracking detection method and visual detection device

ActiveCN113552133AStable positioning measurement functionDimensional accurate detectionImage enhancementImage analysisEngineeringVisual perception

The invention relates to the technical field of battery cell detection, in particular to a battery cell skirt edge cracking detection method and a visual detection device, by processing a battery cell image, n point locations of a skirt edge line segment and fitting a battery cell side edge straight line are obtained, whether the skirt edge cracks or not is detected and judged by detecting the distance from the skirt edge to the side edge of the battery cell main body, the detection accuracy is improved by using the method, the method has the advantages of good interactivity, strong anti-interference capability, stable detection system and stable machine vision image processing logic, and the detection efficiency is high. Meanwhile, accurate and clear pictures can be obtained through a visual detection device and a battery cell image obtaining method, the stable positioning measurement function is achieved, the cracking condition of the battery cell skirt edge can be accurately detected through the obtained images, the battery cell production quality is guaranteed, and the detection efficiency is improved.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

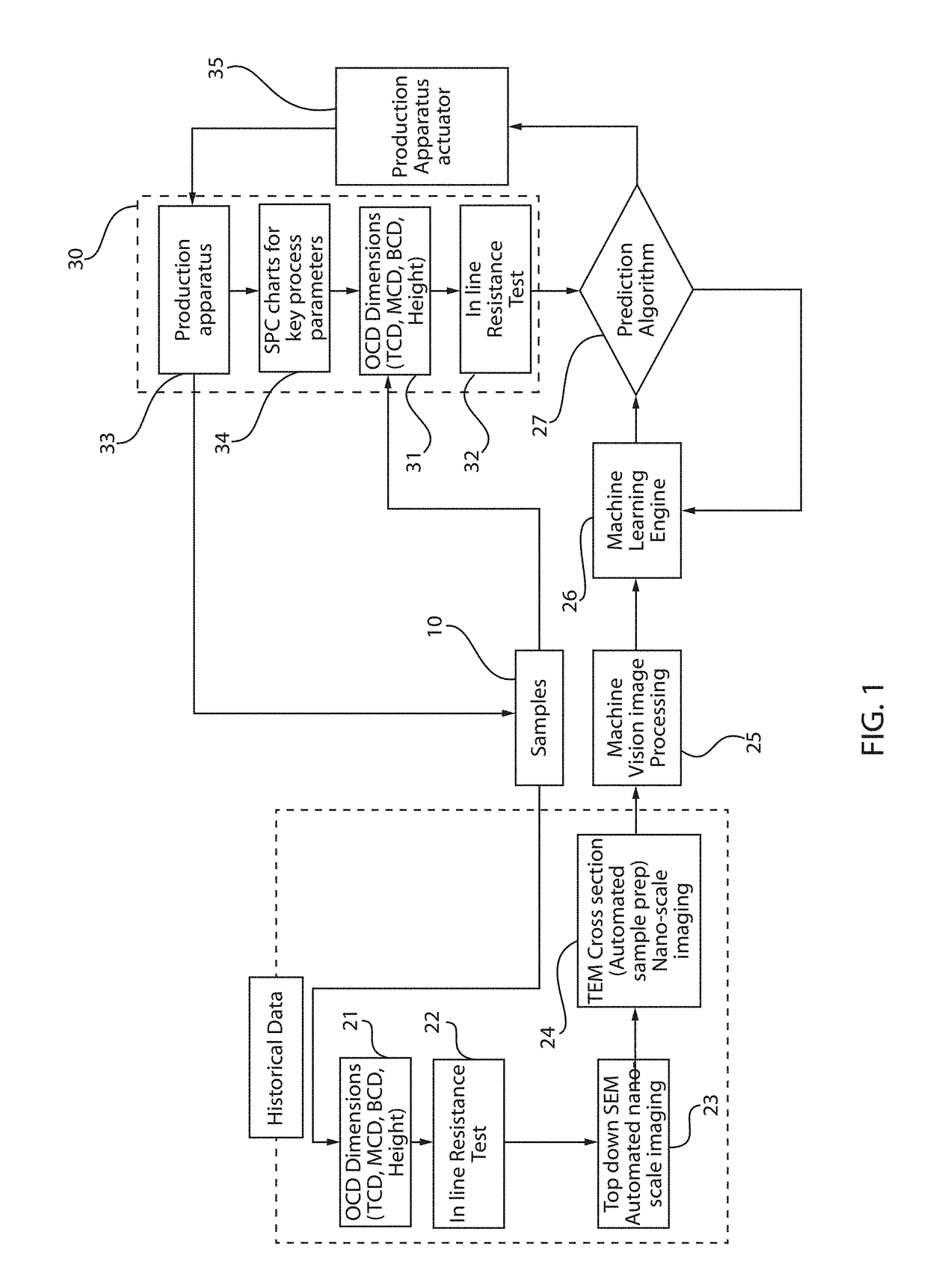

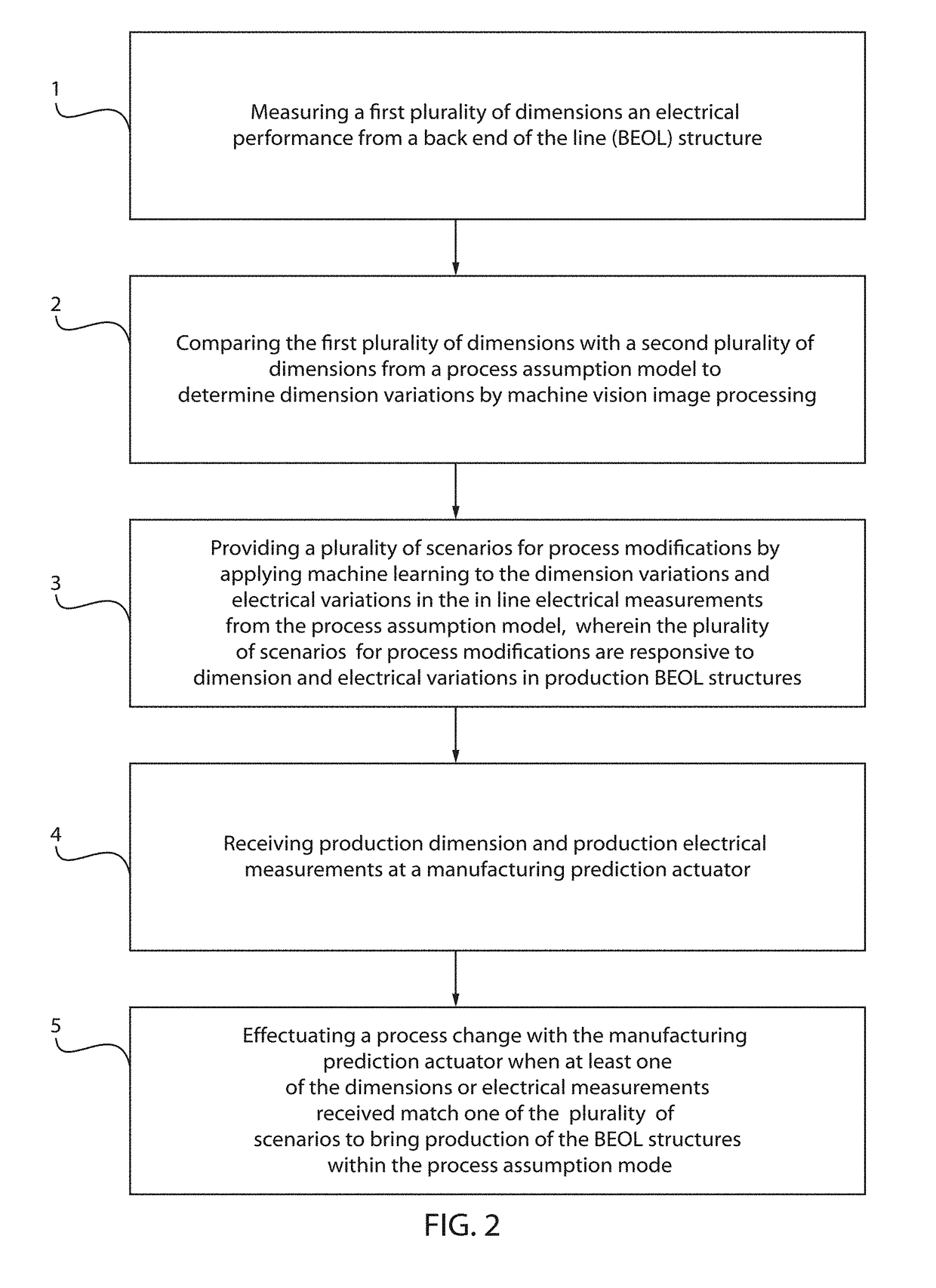

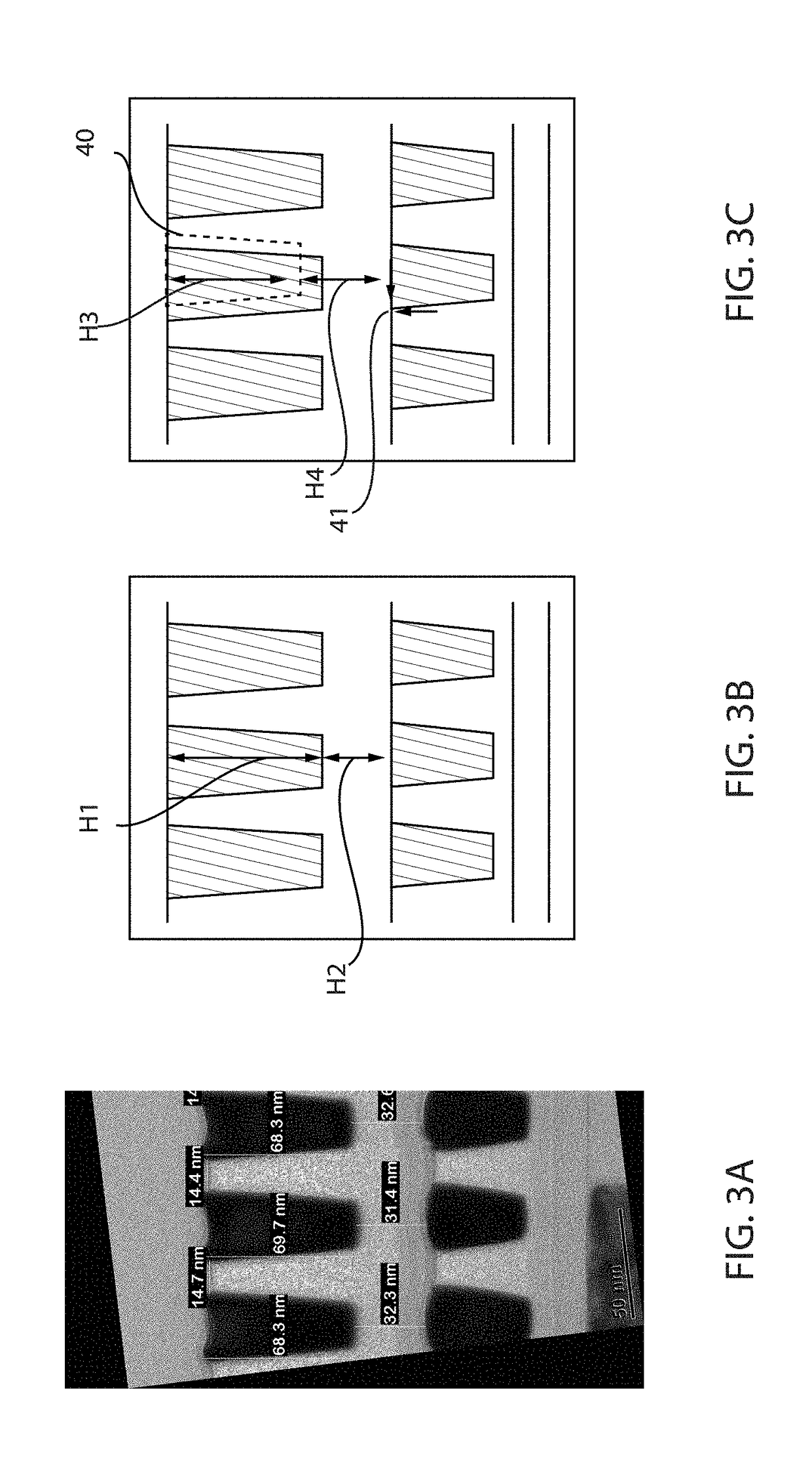

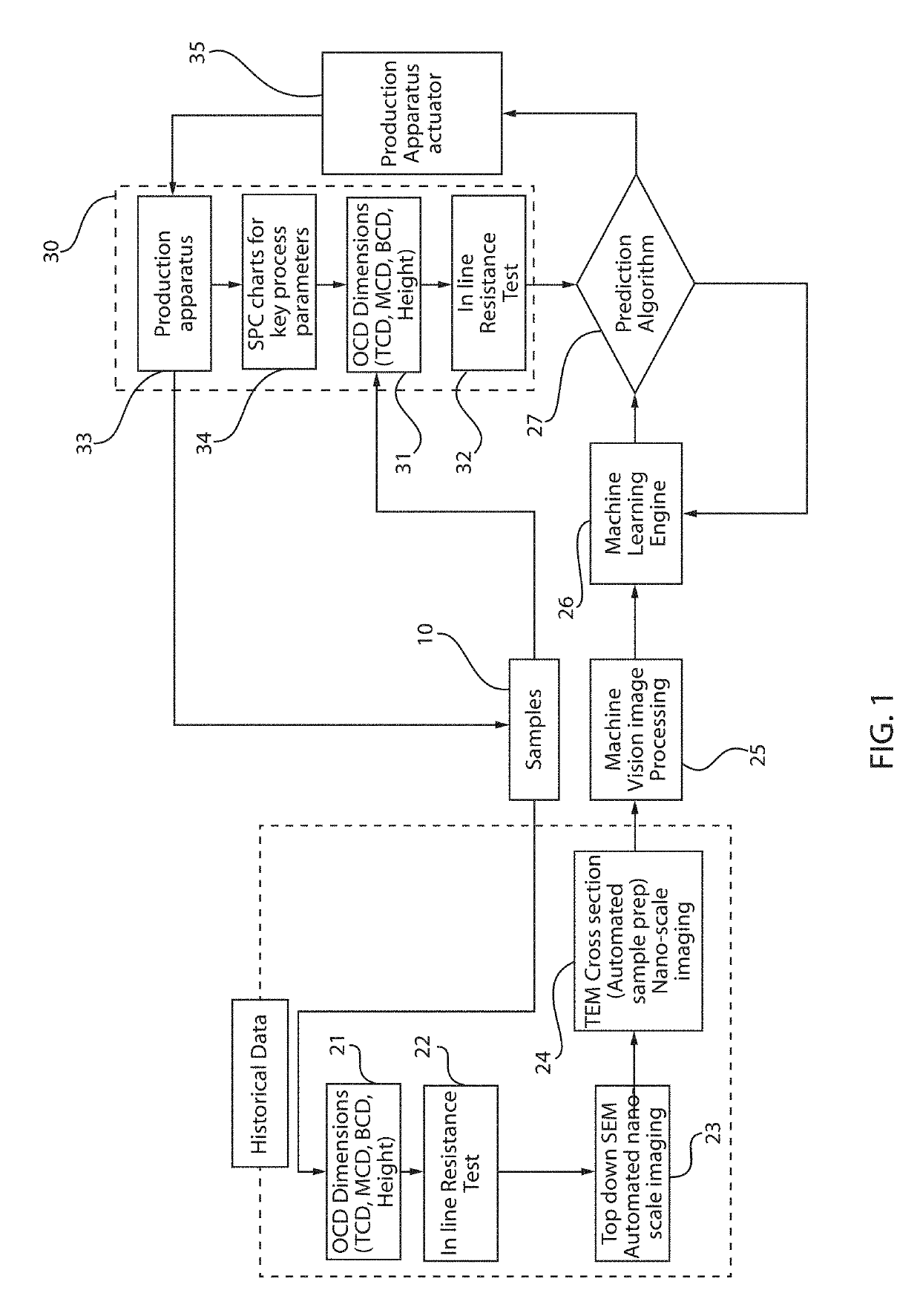

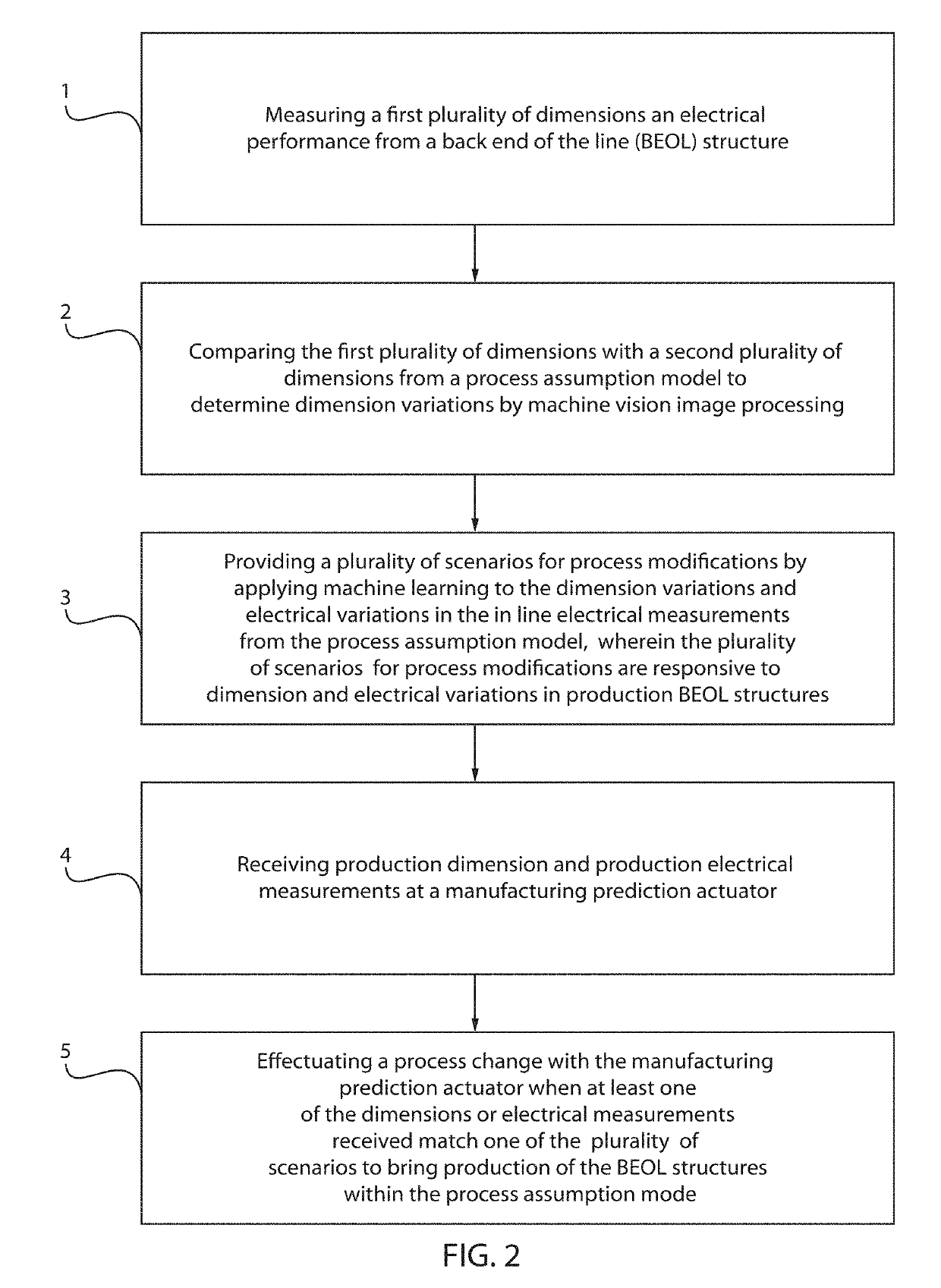

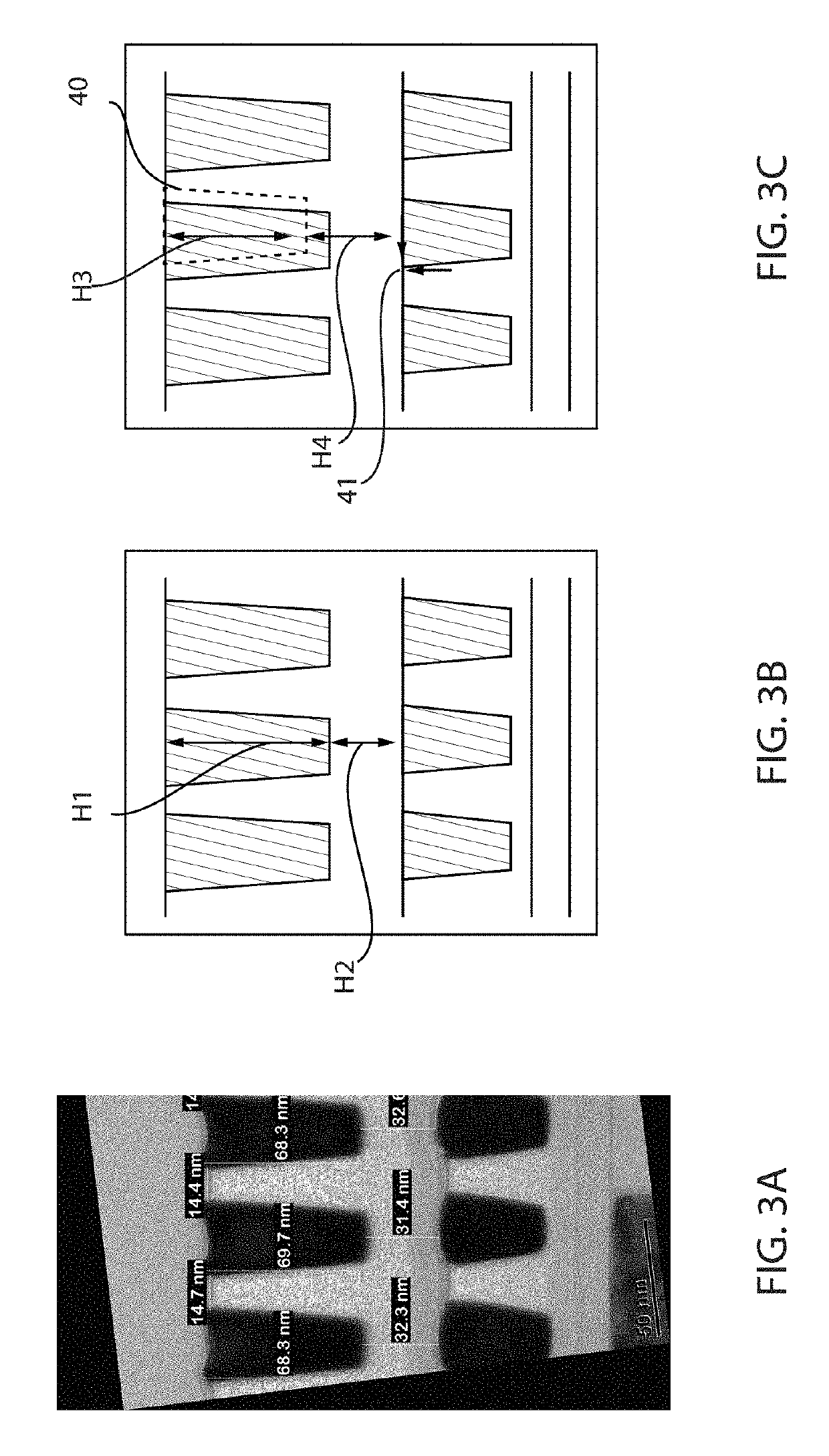

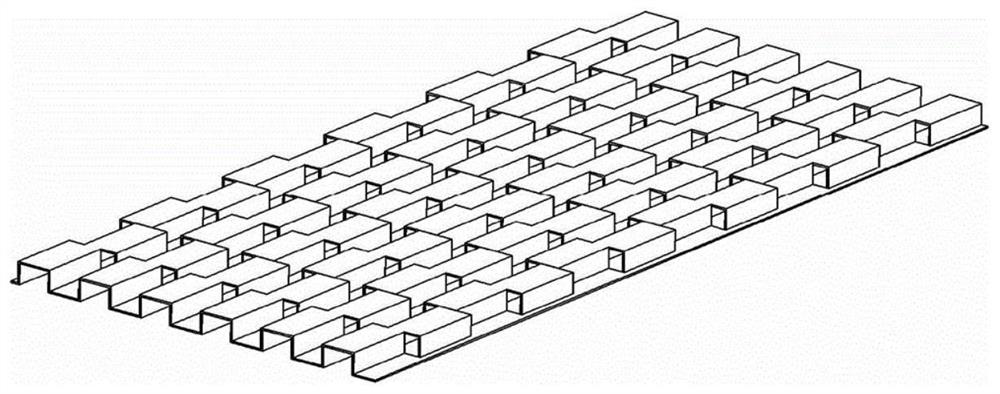

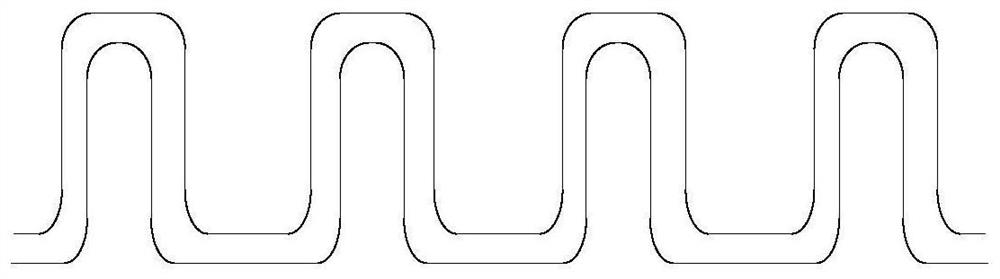

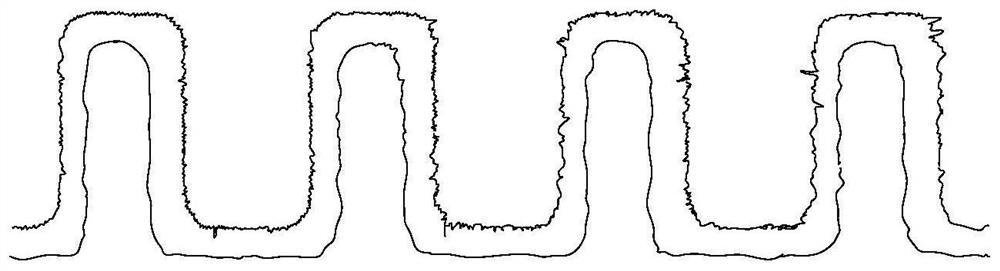

Automated method for integrated analysis of back end of the line yield, line resistance/capacitance and process performance

ActiveUS20180349538A1Semiconductor/solid-state device testing/measurementKnowledge representationCapacitanceElectricity

A method of electrical device manufacturing that includes measuring a first plurality of dimensions and electrical performance from back end of the line (BEOL) structures; and comparing the first plurality of dimensions with a second plurality of dimensions from a process assumption model to determine dimension variations by machine vision image processing. The method further includes providing a plurality of scenarios for process modifications by applying machine image learning to the dimension variations and electrical variations in the in line electrical measurements from the process assumption model. The method further includes receiving production dimension measurements and electrical measurements at a manufacturing prediction actuator. The at least one of the dimensions or electrical measurements received match one of the plurality of scenarios the manufacturing prediction actuator using the plurality of scenarios for process modifications effectuates a process change.

Owner:IBM CORP

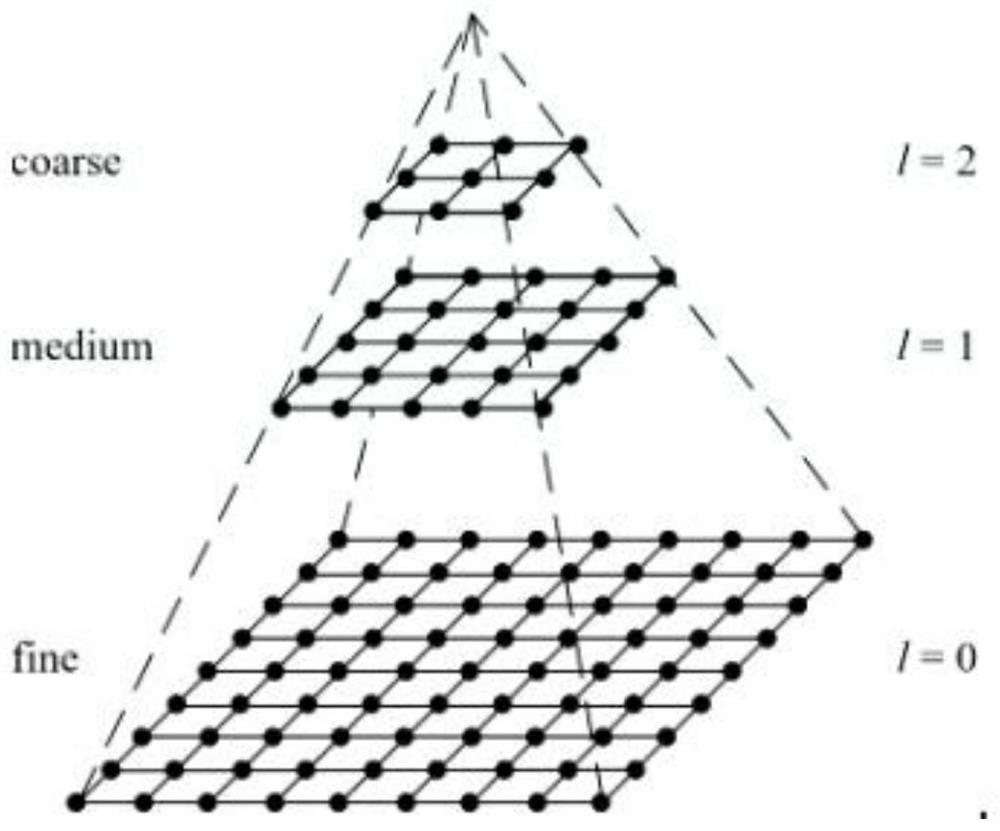

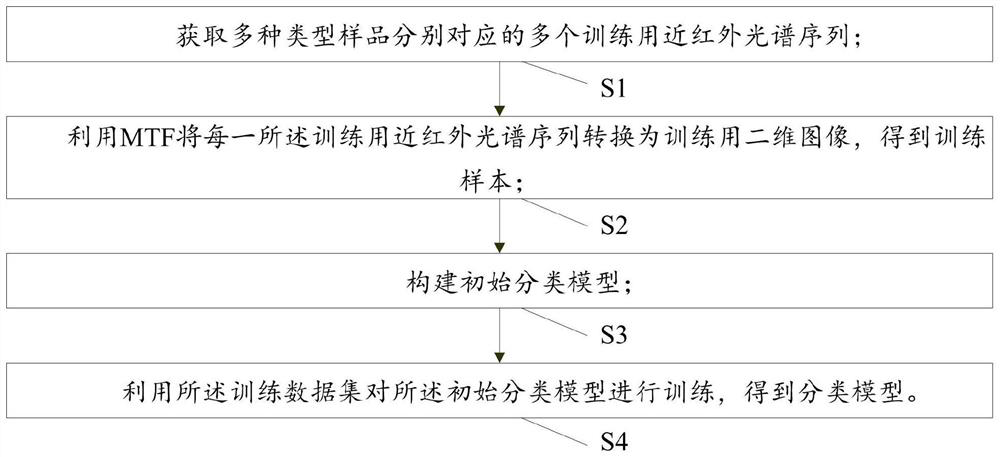

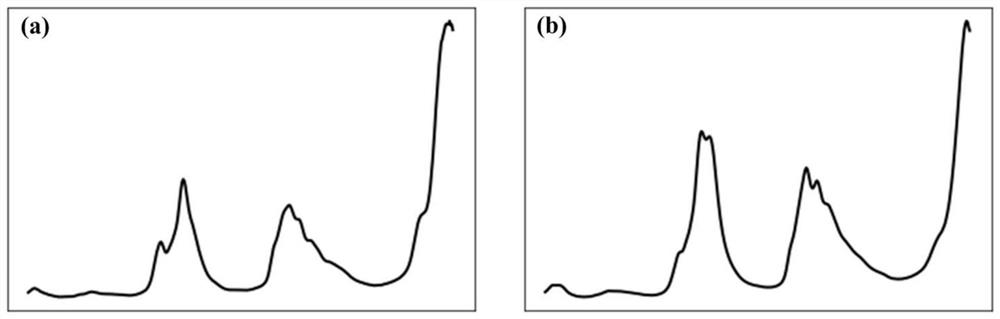

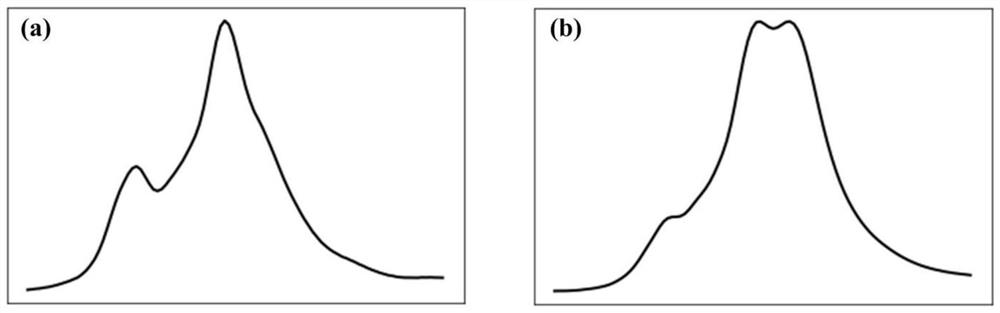

Near infrared spectrum classification model training method and system and classification method and system

PendingCN113378971AImprove classification accuracyPreserve integrityCharacter and pattern recognitionNeural architecturesData setAlgorithm

The invention relates to a near infrared spectrum classification model training method and system, and a classification method and system, and the method comprises the steps of converting each training near infrared spectrum sequence into a training two-dimensional image through an MTF, and obtaining a training data set; and constructing an initial classification model, and training the initial classification model by using the training data set to obtain a classification model. A near-infrared spectrum sequence is integrally converted into an image by introducing an MTF method, the dependency of an original spectrum sequence on wavelength and the integrity of characteristics are reserved, a one-dimensional spectrum sequence is encoded into an image, the powerful advantage of machine vision image processing can be applied to classification and recognition of one-dimensional near-infrared spectrums, and the classification accuracy of the classification model can be obviously improved. By using the classification model, the near infrared spectrum sequence can be classified more accurately.

Owner:YANSHAN UNIV

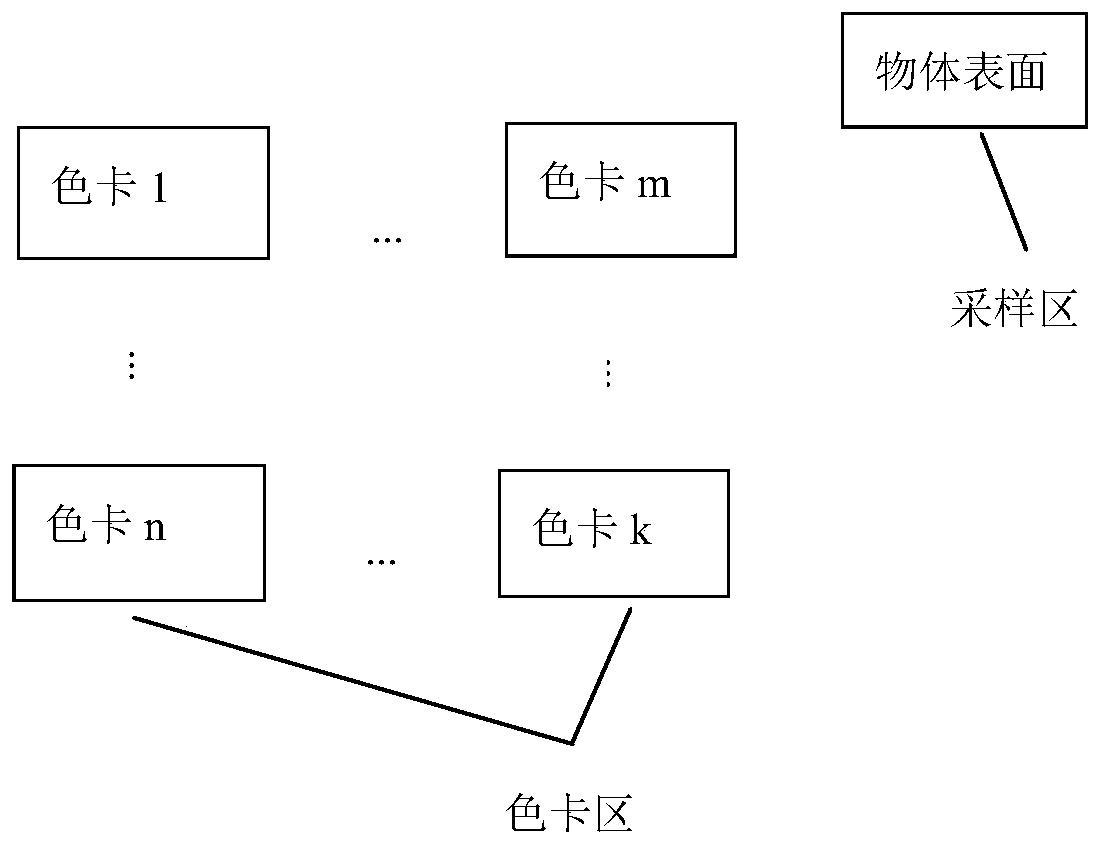

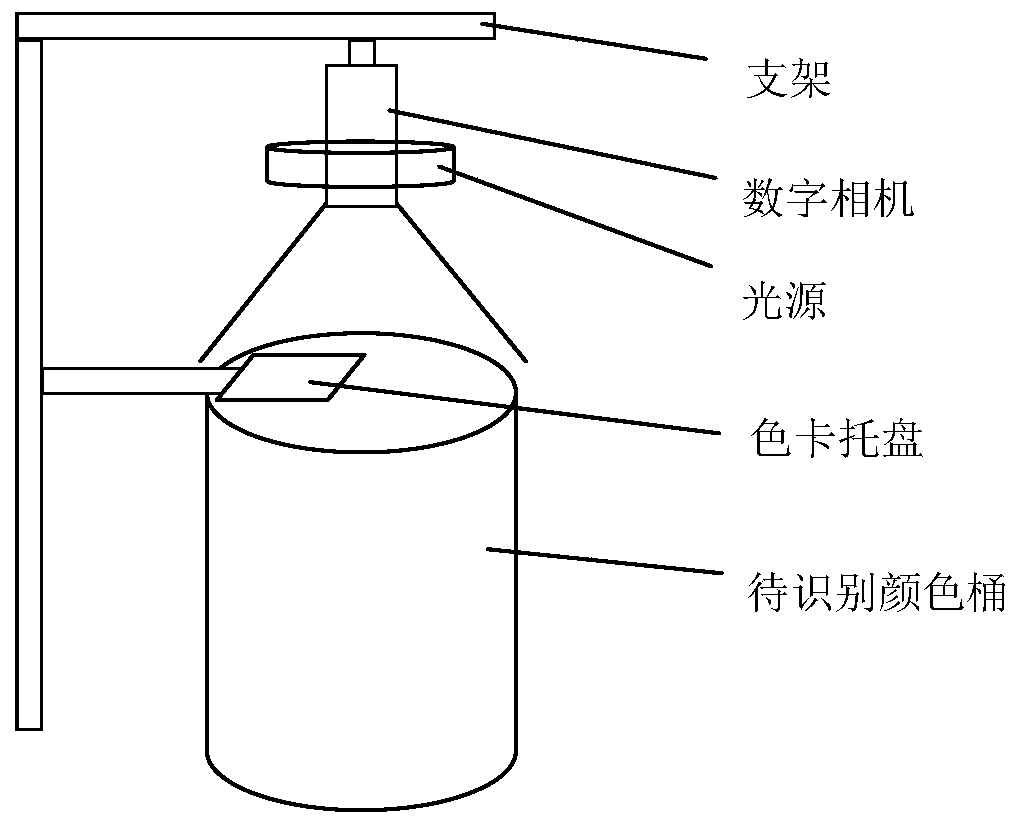

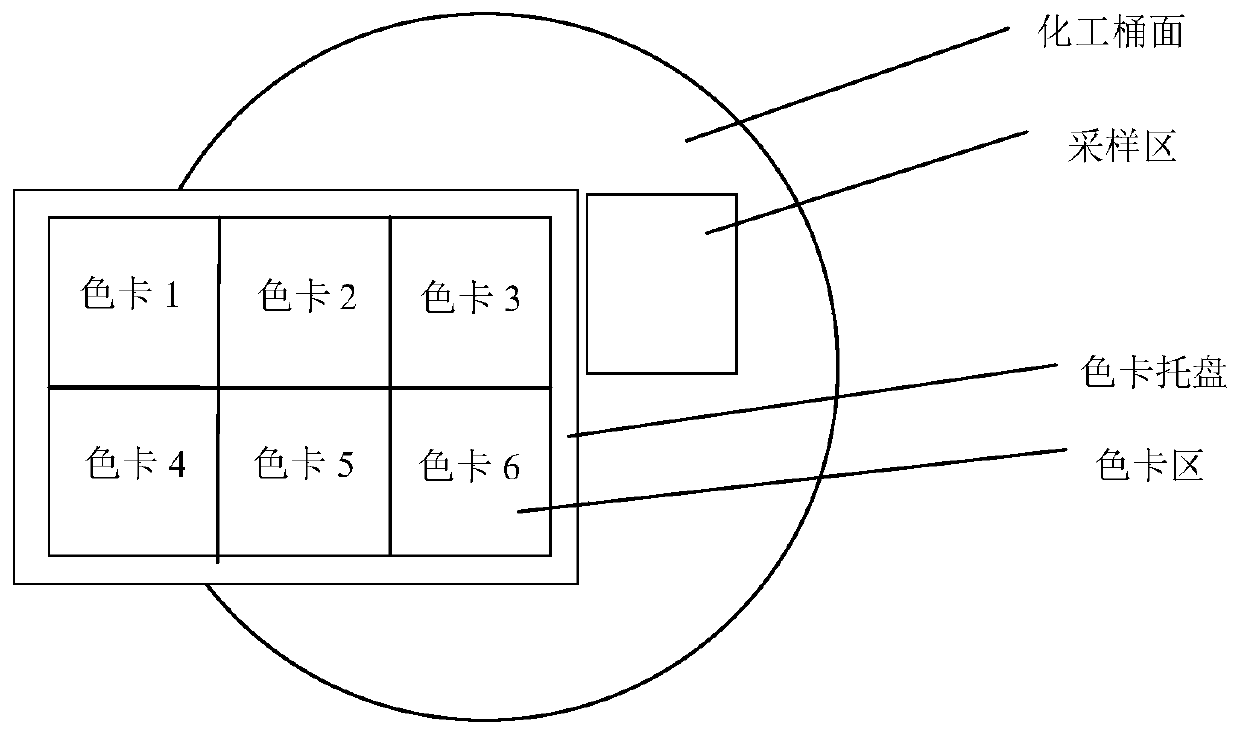

Machine vision method for target color recognition adapting to illumination change

ActiveCN110807817AAvoid influenceIncrease flexibilityImage analysisImage manipulationColor recognition

The invention discloses a target color recognition machine vision method adapting to illumination change, and relates to a machine vision image processing technology of a chemical filling workshop. The identification area is divided into a comparison color card area and a color sampling area, the comparison color card area is divided into a plurality of parts, and a color card for comparison is placed in each part. The color sampling area is an area for collecting colors to be identified. the comparison color card area and the color acquisition area receive the same and uniform external lightsource irradiation. The method is divided into two stages: in a color calibration stage, extracting a color characteristic value of a color card, calculating a color characteristic value of a sample,and correcting the color characteristic; the color identification stage comprises the following steps: placing a sample of which the color needs to be identified in a color sampling area, and calculating a color characteristic value; correcting the color characteristic value; calculating a color characteristic value of the comparison color card; adopting a function to carry out calculation, and carrying out color discrimination. The method can adapt to illumination changes, more colors can be recognized, and similar colors can be distinguished.

Owner:CHANGCHUN BEIFANG INSTR EQUIP +1

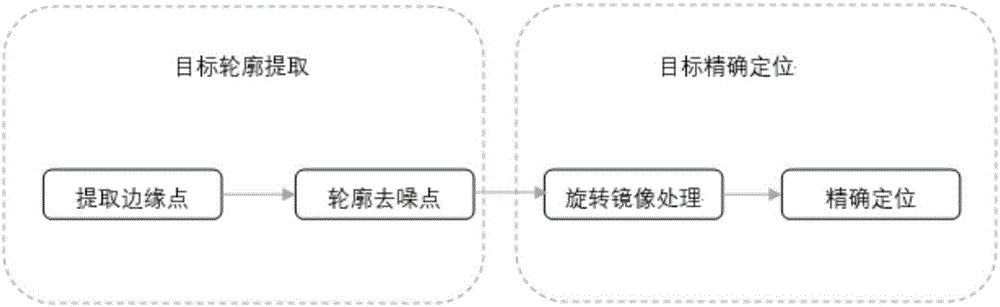

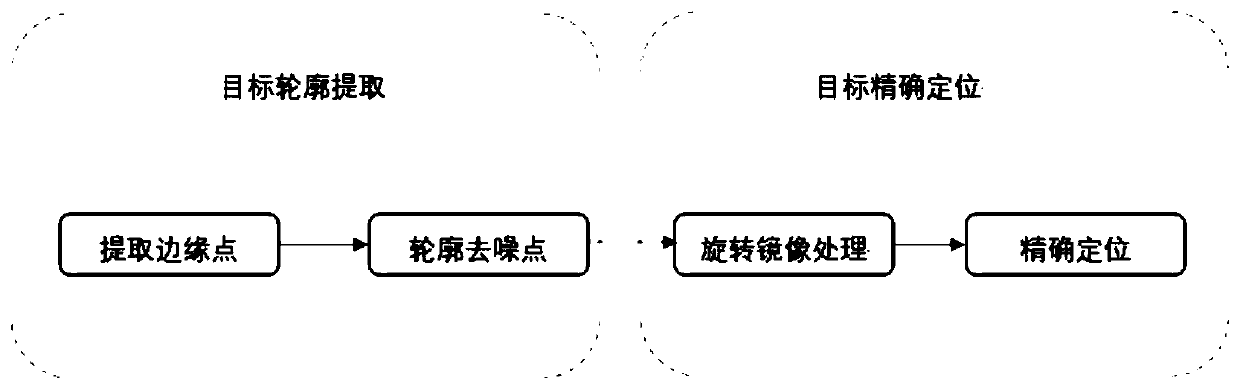

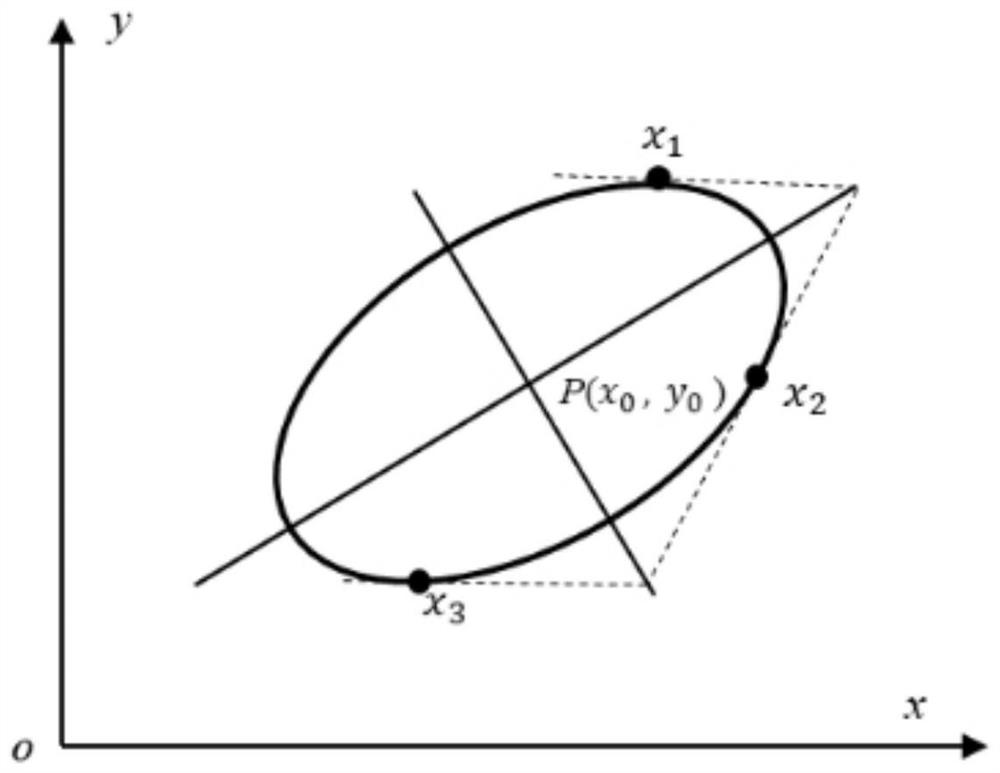

Precise positioning method for circular object with thickness interference

ActiveCN106650717ASolve the problem of rotating mirrorEliminate detection errorsCharacter and pattern recognitionPoint densityEdge based

The invention belongs to the technical field of machine vision image processing, and particularly relates to a precise positioning method for a circular object with thickness interference. According to the invention, a thickness noise removing method based on the edge density is used to eliminate the interference of thickness noise to the circular object; the noise center position relation is used to solve a rotation mirror problem, and the rotation direction of the object is calculated; and the size of the rotation angle of the object is calculated through a center offset algorithm for an object with a prominent column in the middle. The method comprises the concrete steps that the edge contour after removing noise from thickness is extracted based on the edge point density; rotation mirror processing is carried out based on the thickness noise center; and accurate target positioning is carried out based on the center point offset. The method provided by the invention is particularly applicable to rapid and accurate detection and positioning of the circular object with thickness interference in an industrial environment, and has the advantages of high positioning accuracy, efficient processing rate and great anti-noise ability.

Owner:FUDAN UNIV

Automated method for integrated analysis of back end of the line yield, line resistance/capacitance and process performance

ActiveUS10303829B2Semiconductor/solid-state device testing/measurementKnowledge representationCapacitanceDimension measurement

A method of electrical device manufacturing that includes measuring a first plurality of dimensions and electrical performance from back end of the line (BEOL) structures; and comparing the first plurality of dimensions with a second plurality of dimensions from a process assumption model to determine dimension variations by machine vision image processing. The method further includes providing a plurality of scenarios for process modifications by applying machine image learning to the dimension variations and electrical variations in the in line electrical measurements from the process assumption model. The method further includes receiving production dimension measurements and electrical measurements at a manufacturing prediction actuator. The at least one of the dimensions or electrical measurements received match one of the plurality of scenarios the manufacturing prediction actuator using the plurality of scenarios for process modifications effectuates a process change.

Owner:INT BUSINESS MASCH CORP

Plate-fin heat exchanger fin machining quality online inspection method based on machine vision

ActiveCN111833305ARealize automatic couplingWith automationImage enhancementImage analysisImaging processingFeature parameter

The invention discloses a plate-fin heat exchanger fin machining quality online inspection method based on machine vision. Based on the above limitations, machine vision, image processing, pattern recognition and deep learning technologies are adopted, a characteristic parameter set related to the geometrical shape, the size, the form and the distribution of notch burrs and the like of the fin isconstructed, a model of a mapping relationship between the characteristic parameter set and an f-Re resistance characteristic curve representing the processing quality of the fin notch is further established, and the processing quality of the fin notch is inspected on line accordingly. According to the method, automatic coupling between fin notch burr characteristics and f-Re resistance characteristic curves can be achieved, so that the notch machining quality is inspected on line, and the method has automation, rapidity and real-time performance which cannot be achieved by a traditional inspection method.

Owner:HANGZHOU DIANZI UNIV

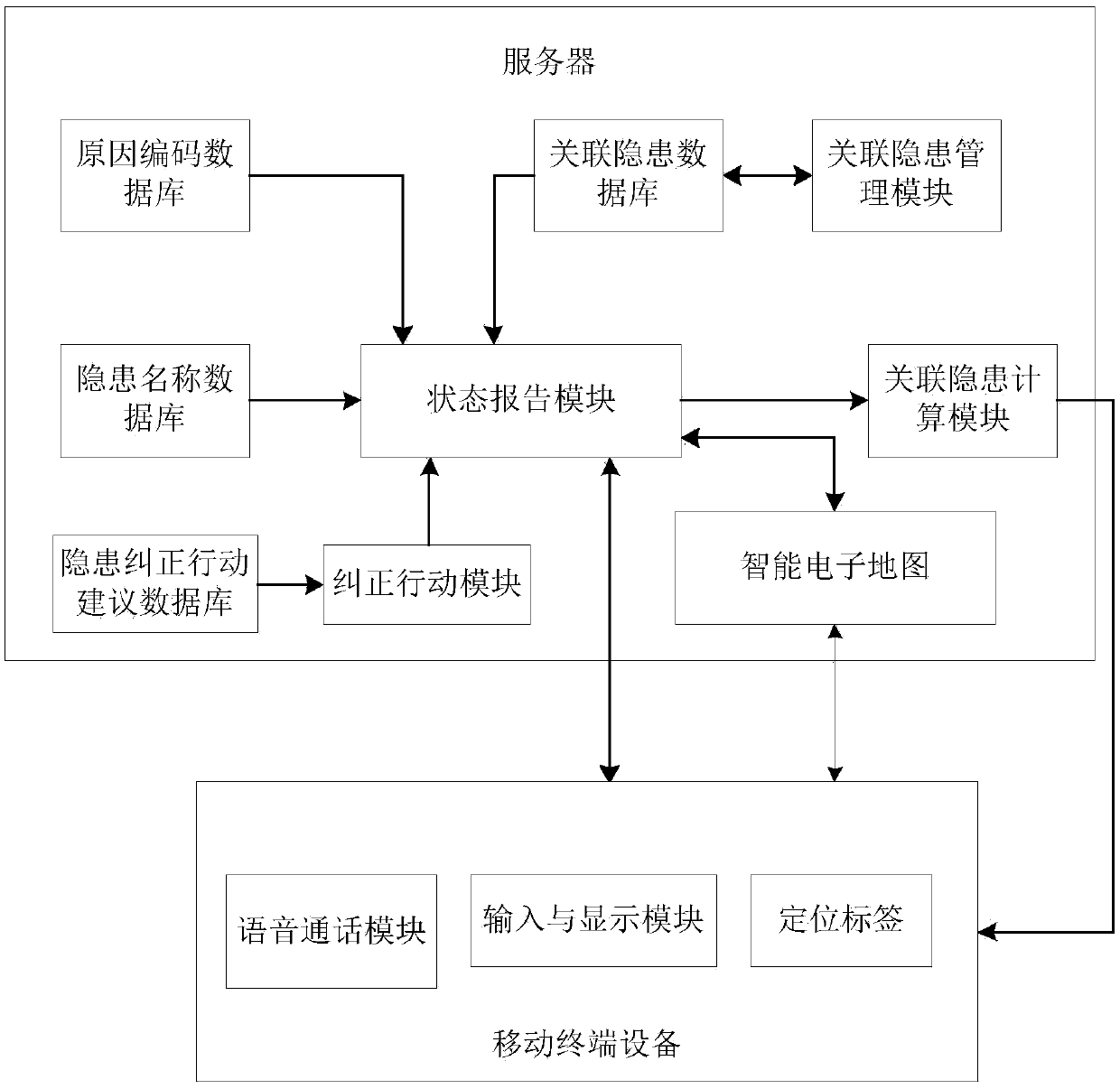

Unsafe behavior reminding system

PendingCN110570623AUnsafe behavior in a timely mannerRemind in timeCharacter and pattern recognitionAlarmsInformation processingImaging processing

The invention relates to an unsafe behavior reminding system. The unsafe behavior reminding system is characterized by comprising a headset, a machine vision camera and a server, the server comprisesa machine vision image processing module, a hidden danger information processing module and an unsafe behavior and voice library, wherein the machine vision image processing module is in charge of processing user behavior image information, performing identity recognition on a user, obtaining a result that whether the user acts unsafely or not and a place where the user acts unsafely and sending an unsafe behavior of the user to the hidden danger inforamtion processing module; and the hidden danger information processing module obtains a fact that a certain user acts unsafely from the machinevision image processing module and then sends corresponding voice information in the unsafe behavior and voice library to the headset corresponding to the user to remind the user to pay attention to the unsafe behavior. Compared with the prior art, the system provided by the invention has the advantages that an unsafe behavior of a worker can be timely reminded to personnel working in the place.

Owner:宁波欧依安盾安全科技有限公司

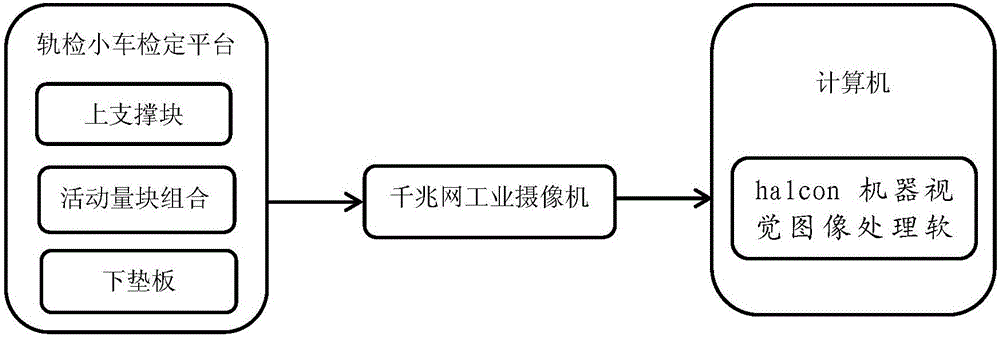

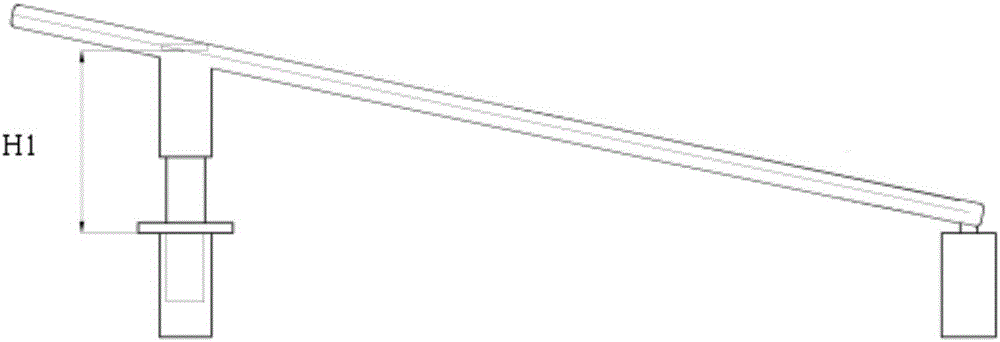

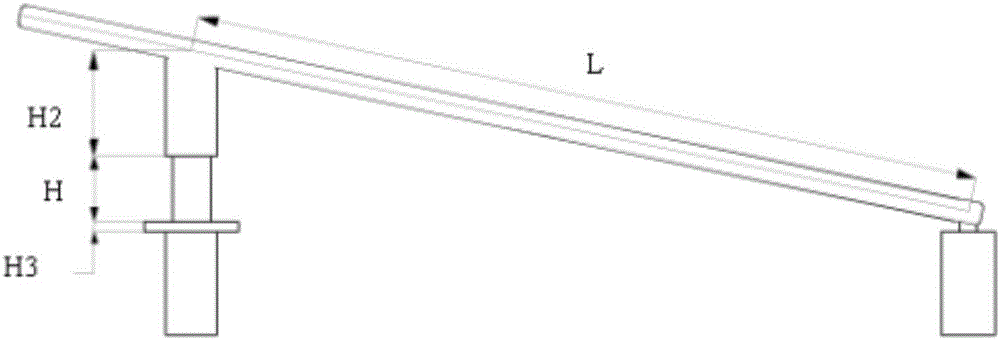

Track-detection-car-verification-platform dip angle reading device based on machine vision and method

ActiveCN106767337AImprove persuasivenessAvoid Human Discrimination ErrorsAngles/taper measurementsImage analysisMachine vision image processingCushion

The invention provides a track-detection-car-verification-platform dip angle reading device based on machine vision and a method. The track-detection-car-verification-platform dip angle reading device comprises a computer provided with halcon machine vision image processing software, a camera, a secondary light source, a track-detection-car verification platform and an active amount block combination. The camera is connected with the computer through a reticle, the active amount block combination is put between an upper supporting block and a lower cushion block of the track-detection-car verification platform, and the camera is matched with the secondary light source to be right opposite to the active amount block combination. The track-detection-car-verification-platform dip angle reading device is based on the machine vision for replacing traditional artificial data reading, the objectivity and the accuracy in the verification process are effectively guaranteed, and the verification result is more scientific.

Owner:SOUTH SURVEYING & MAPPING INSTR +1

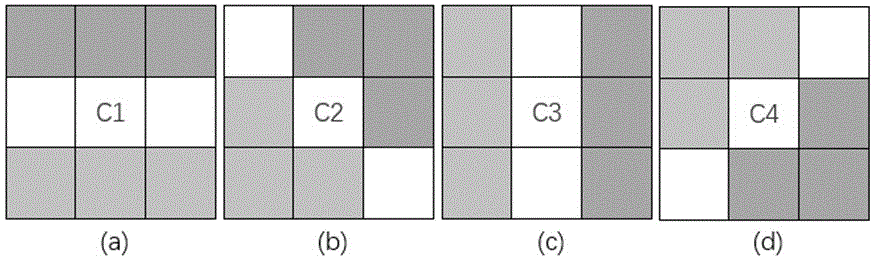

Multi-CCD spliced scanning mechanism and image processing method through same

InactiveCN104702813AHigh magnificationImprove resolutionPictoral communicationImaging processingField of view

The invention relates to a multi-CCD spliced scanning mechanism and an image processing method through the same and belongs to the technical field of machine vision processing. The mechanism comprises a fixation support, a fixation plate is fixed on the fixation support, a first CCD and a second CCD are arranged on the fixation plate in parallel, a first detection lens is fixed at the bottom of the first CCD, a second detection lens is fixed at the bottom of the second CCD, a first LED shiner and a second LED shiner are arranged below the first detection lens and the second detection lens in a fit mode and are disposed on the two sides of an imaging light path of the first LED shiner and the second LED shiner, and an object to be measured is arranged below the first LED shiner and the second LED shiner in a fit mode. By means of the mechanism and the method, within the controllable cost, the better resolution can be obtained for equally detected wide-view objects to be detected, and the mechanism and the method can be applied to actual production requirements reasonably.

Owner:HANGZHOU POWER TECH CO LTD

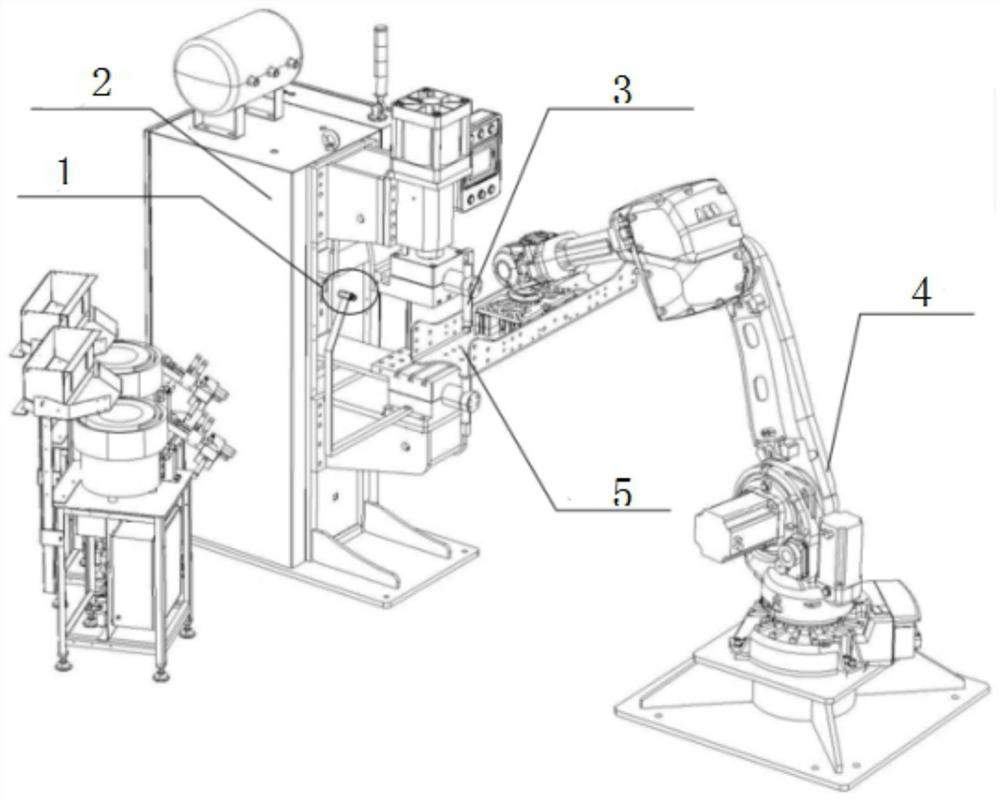

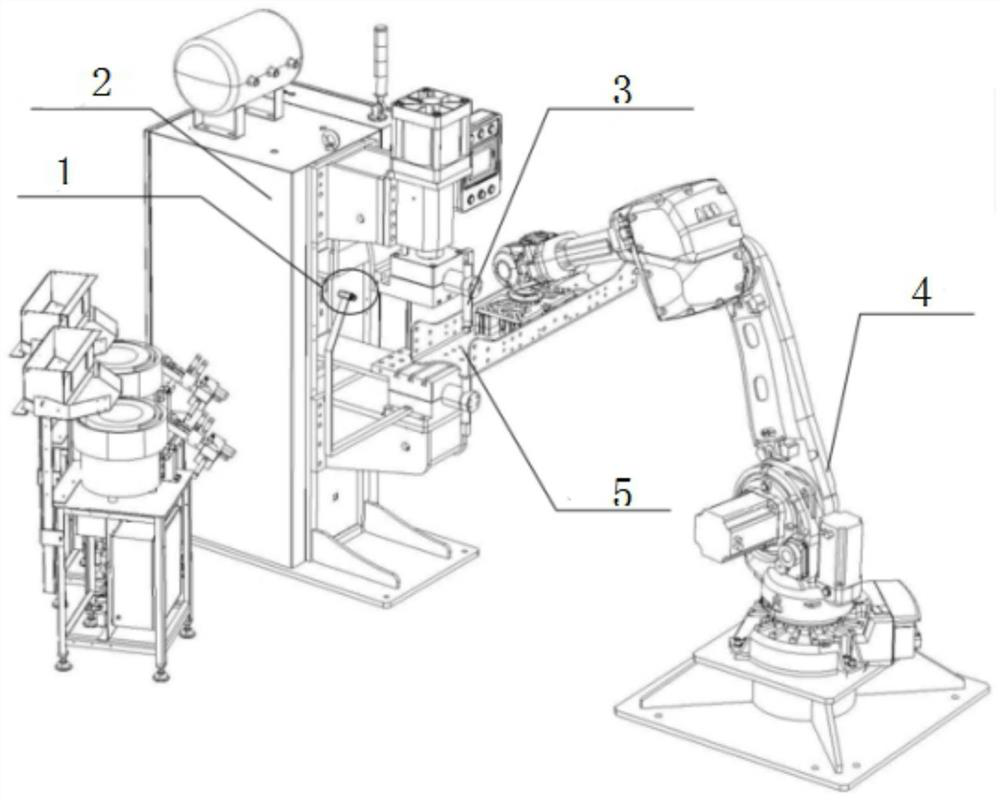

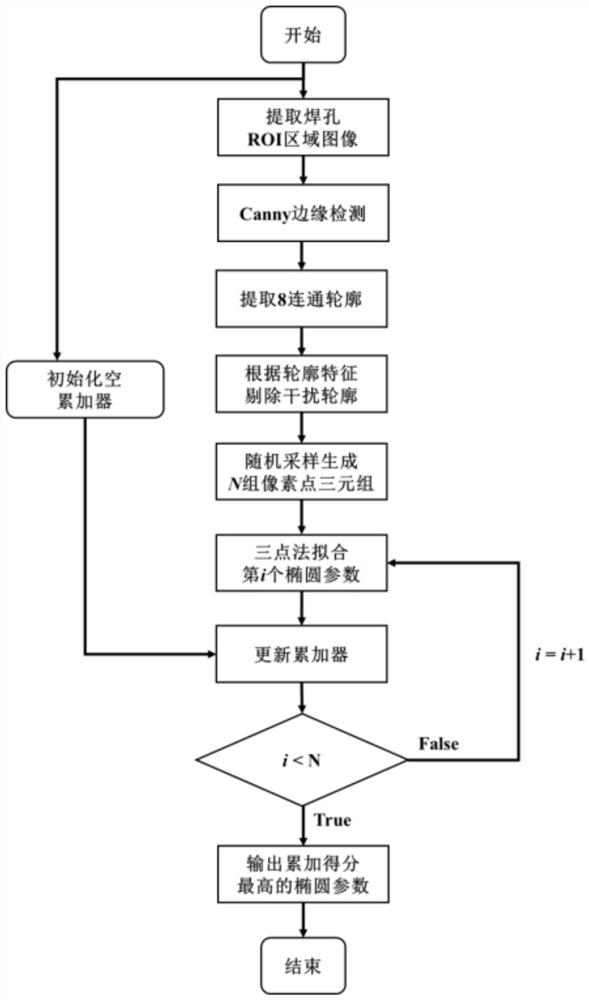

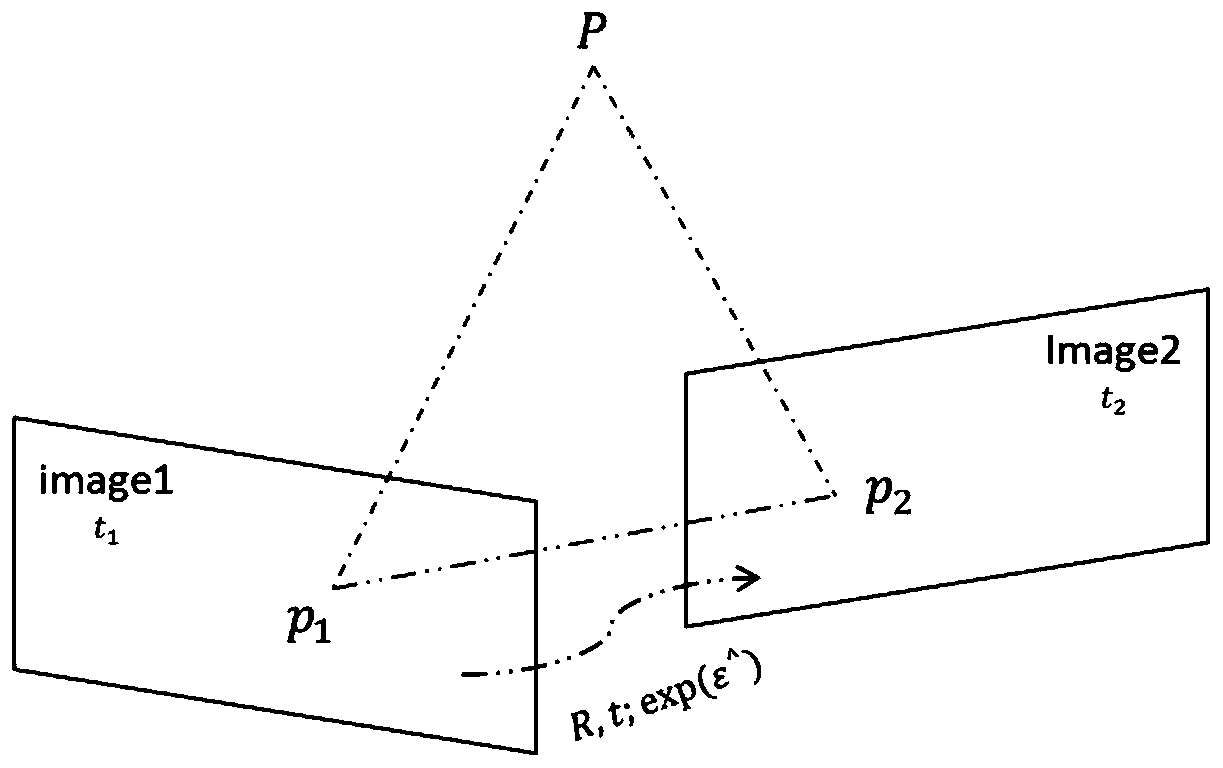

High-precision projection welding error compensation system based on robot hand-eye visual feedback

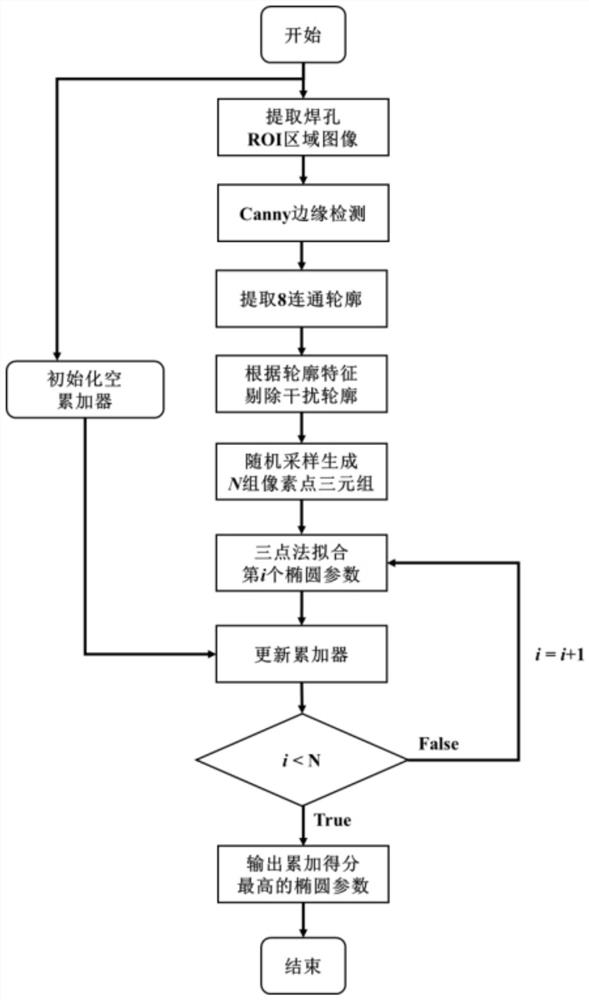

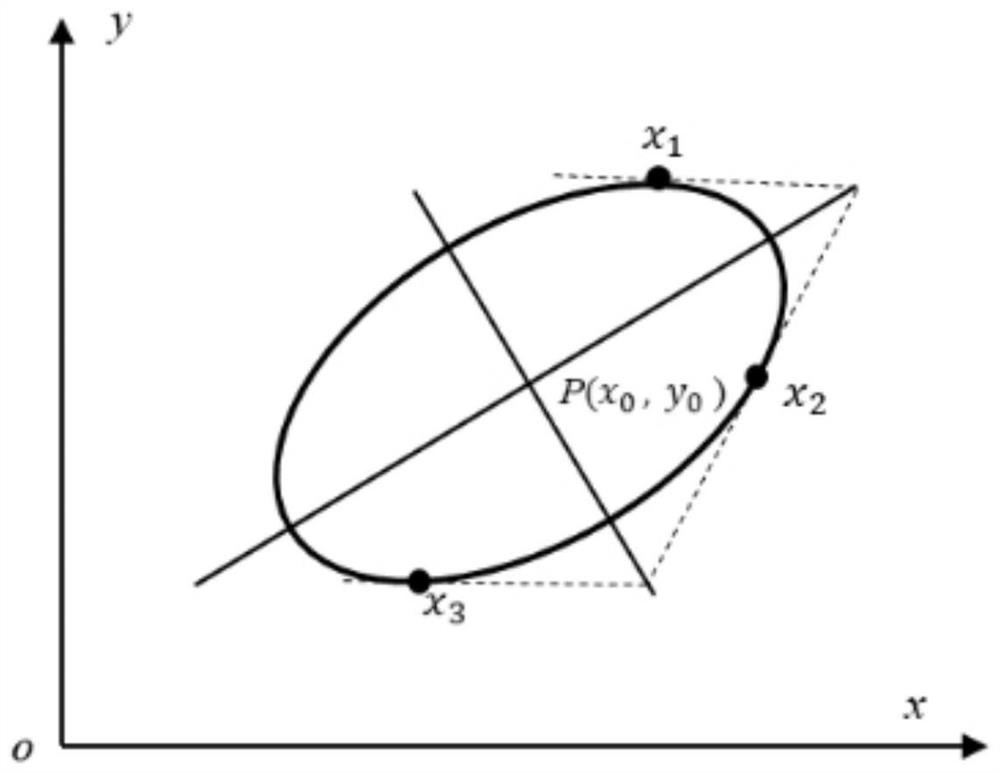

ActiveCN113118604ARealize online compensationImprove welding precisionResistance electrode holdersProgramme-controlled manipulatorRgb imageEdge maps

The invention belongs to the field of machine vision, image processing and robot control, particularly relates to a high-precision projection welding error compensation system based on robot hand-eye visual feedback, and provides the following scheme aiming at solving the problem of robot teaching welding track deviation caused by manufacturing errors of workpieces in an existing robot nut projection welding process. The high-precision projection welding error compensation system comprises a depth camera, welding equipment, a projection welding electrode, a welding robot and a target welding hole; the depth camera and the projection welding electrode are both arranged at one side of the welding equipment, the target welding hole is located below the projection welding electrode, the welding robot is located at the outer side of the welding equipment, and RGB images and depth images of a workpiece welding point area are collected through the depth camera; and welding hole ROI areas of the RGB images are extracted, Canny edge detection is carried out, and edge images are obtained. The high-precision projection welding error compensation system effectively solves the problem of welding track errors caused by workpiece manufacturing, and the welding precision and quality of the robot automatic nut projection welding process are improved.

Owner:SHANGHAI JIAO TONG UNIV

A Precise Positioning Method for Circular Objects with Thickness Interference

ActiveCN106650717BSolve the problem of rotating mirrorEliminate detection errorsCharacter and pattern recognitionEngineeringEdge based

Owner:FUDAN UNIV

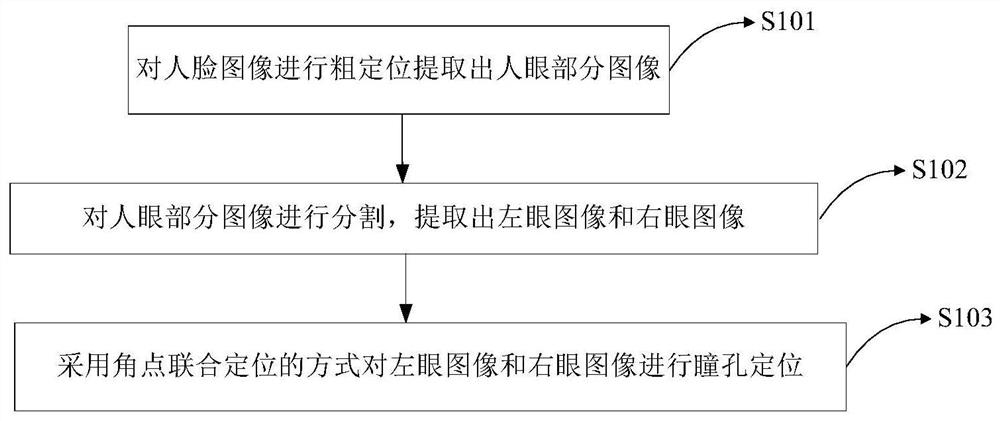

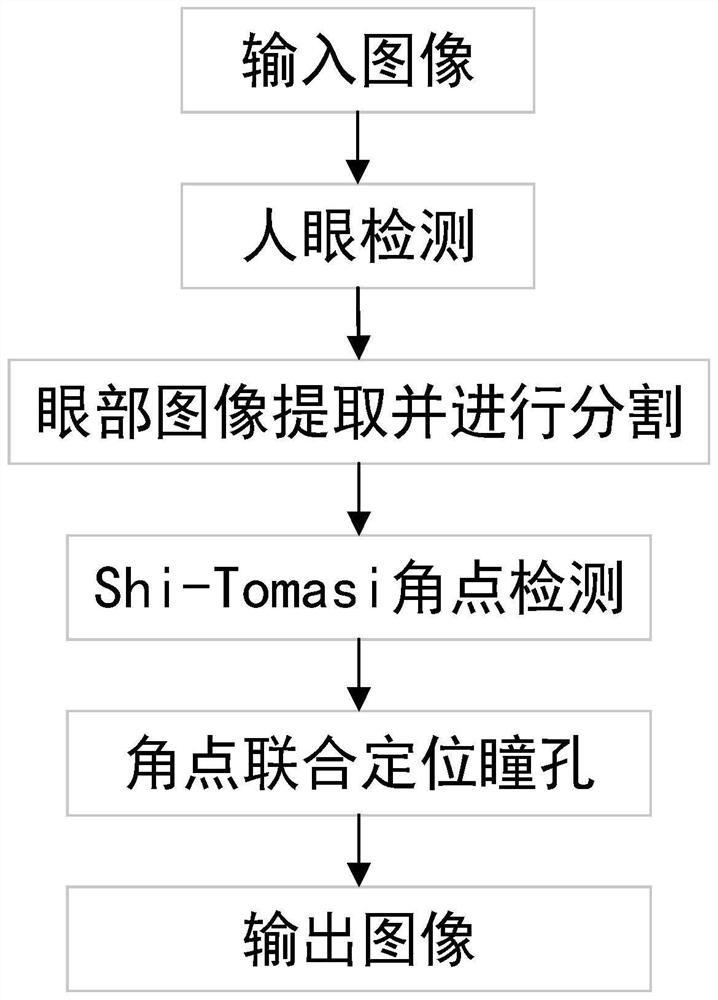

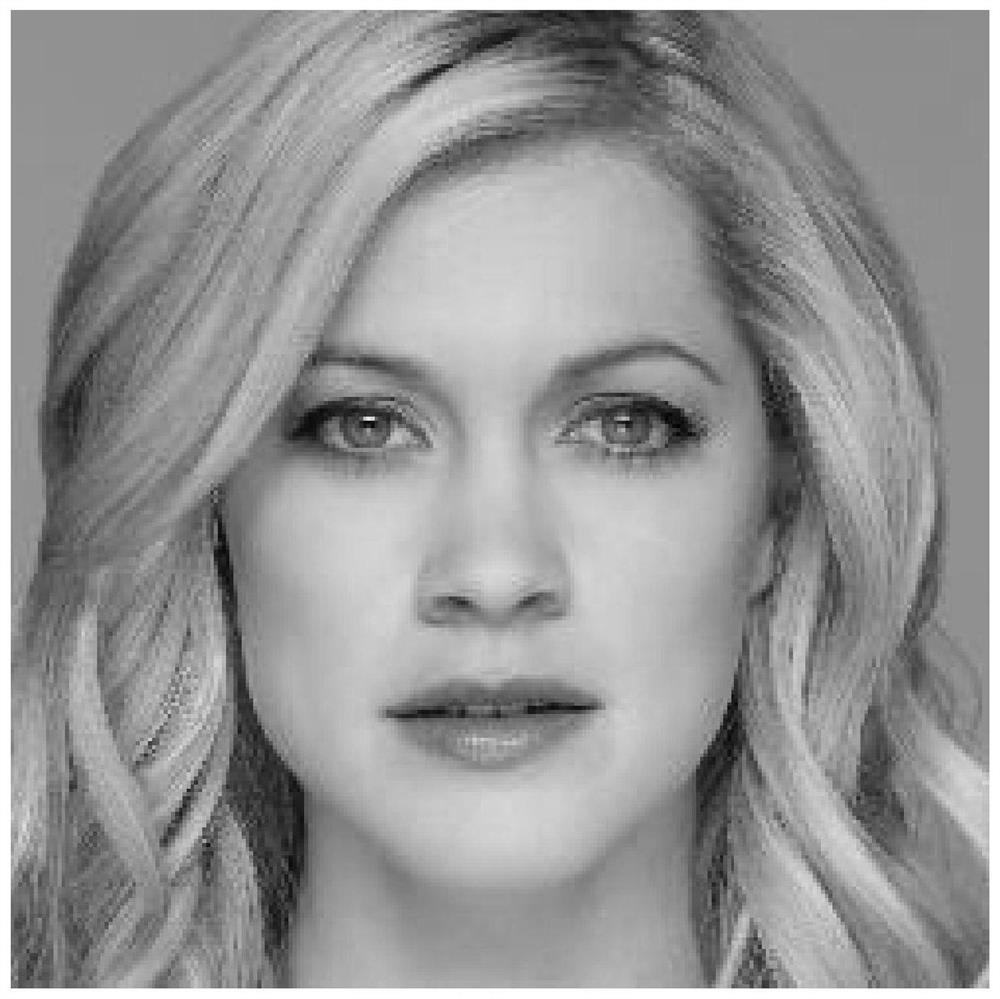

Pupil positioning method and device based on angular point detection

PendingCN114764944AReduce mistakesHigh precisionCharacter and pattern recognitionOphthalmologyAngular point

The invention relates to the field of machine vision image processing, in particular to a pupil positioning method and device based on angular point detection. According to the method and device, firstly, a face image is subjected to coarse positioning, and a human eye part image is extracted; segmenting the human eye part image, and extracting a left eye image and a right eye image; and finally, performing pupil positioning on the left eye image and the right eye image by adopting a corner joint positioning mode. According to the invention, the angular point detection algorithm is applied to the eye image and is improved, so that errors are reduced when pupil positioning is carried out, and higher precision is obtained.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

High-precision projection welding error compensation system based on robot hand-eye visual feedback

ActiveCN113118604BRealize online compensationImprove welding precisionResistance electrode holdersProgramme-controlled manipulatorRgb imageEdge maps

Owner:SHANGHAI JIAOTONG UNIV

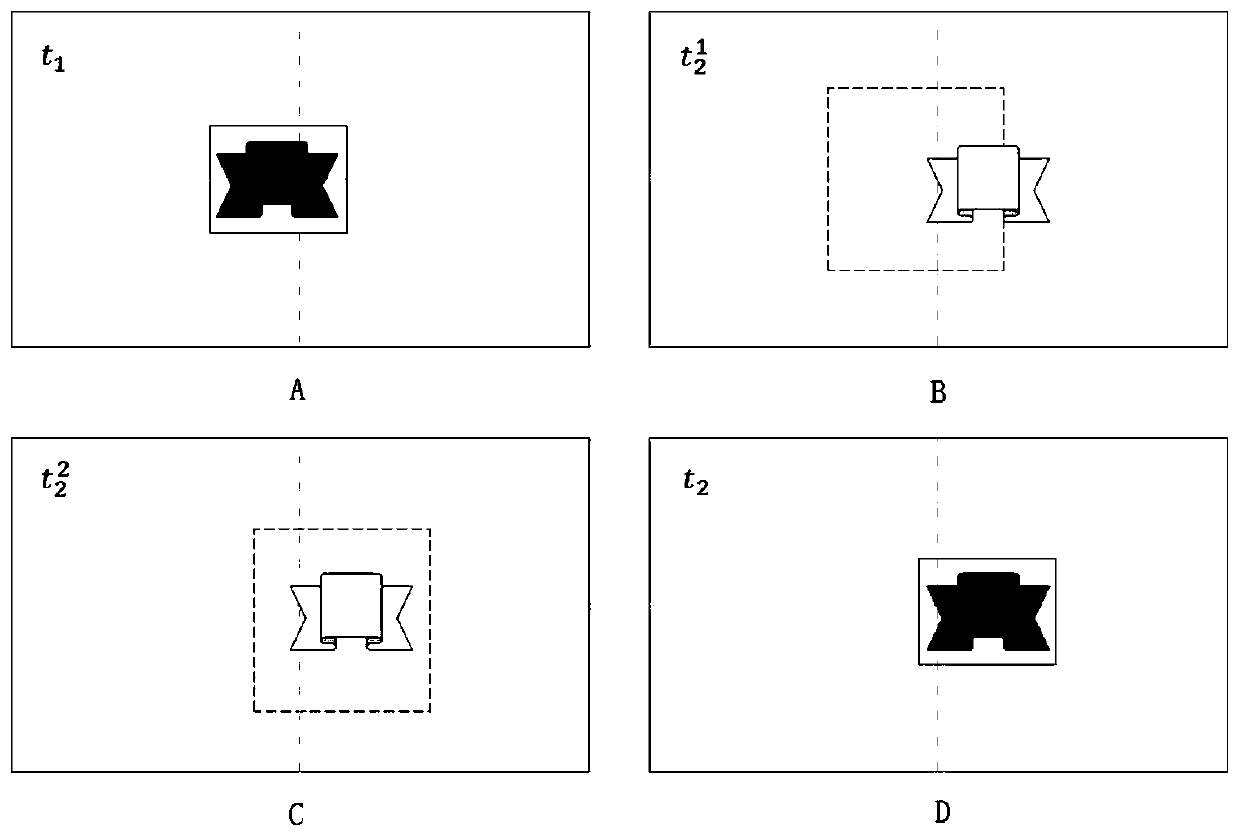

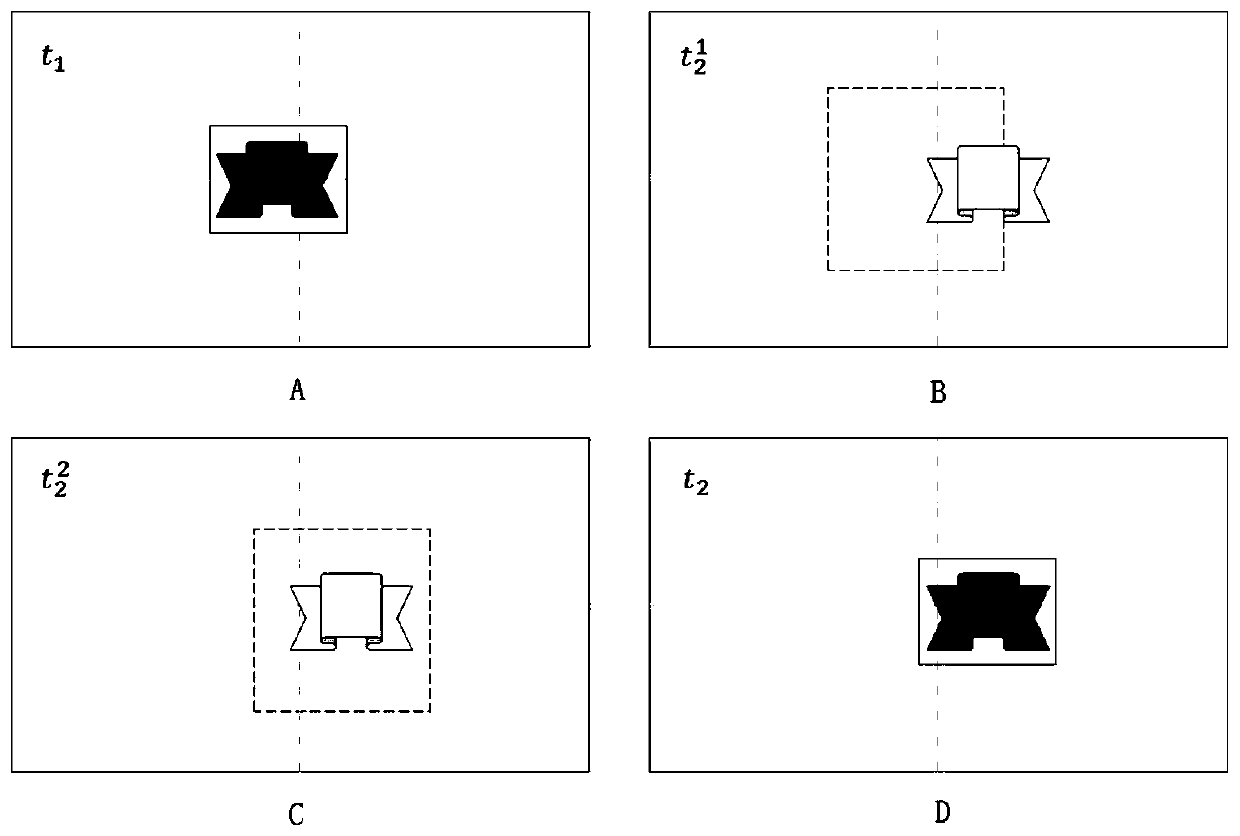

Self-adaptive target ROI positioning method for solar panel cleaning robot

ActiveCN111144406AAvoid detectionImprove detection efficiencyInstruments for road network navigationImage analysisEngineeringVisual perception

The invention belongs to the technical field of machine vision image processing, and particularly relates to a self-adaptive ROI target positioning method for a solar panel cleaning robot. According to the invention, the characteristic of limited position change of a target in two frames of images is utilized, and the detection result of the previous frame is fused with the sensor motion information to compensate the target position change; the possible region of interest of the target in the current image is estimated, the detection range is reduced, interference caused by large calculation amount of the whole image scanning target and a useless background region is avoided, the method focuses on an effective region, and the target can be efficiently and accurately detected in real time.According to the invention, the problems of large operand, poor real-time performance, much interference, easy target loss and the like caused by wide detection range, complex background and motion change of the cleaning robot on the solar panel are solved, the detection efficiency and stability of the cleaning robot are greatly improved, and the cleaning robot can quickly, efficiently and accurately complete the full-automatic cleaning work of the solar panel.

Owner:FUDAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com