Intelligent composite material net piece sorting machine

A composite material and sorting machine technology, applied in sorting and other directions, can solve the problems of low production efficiency, low degree of automation, high labor intensity, etc., achieve accurate mesh sorting, improve production efficiency, and ensure the effect of factory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

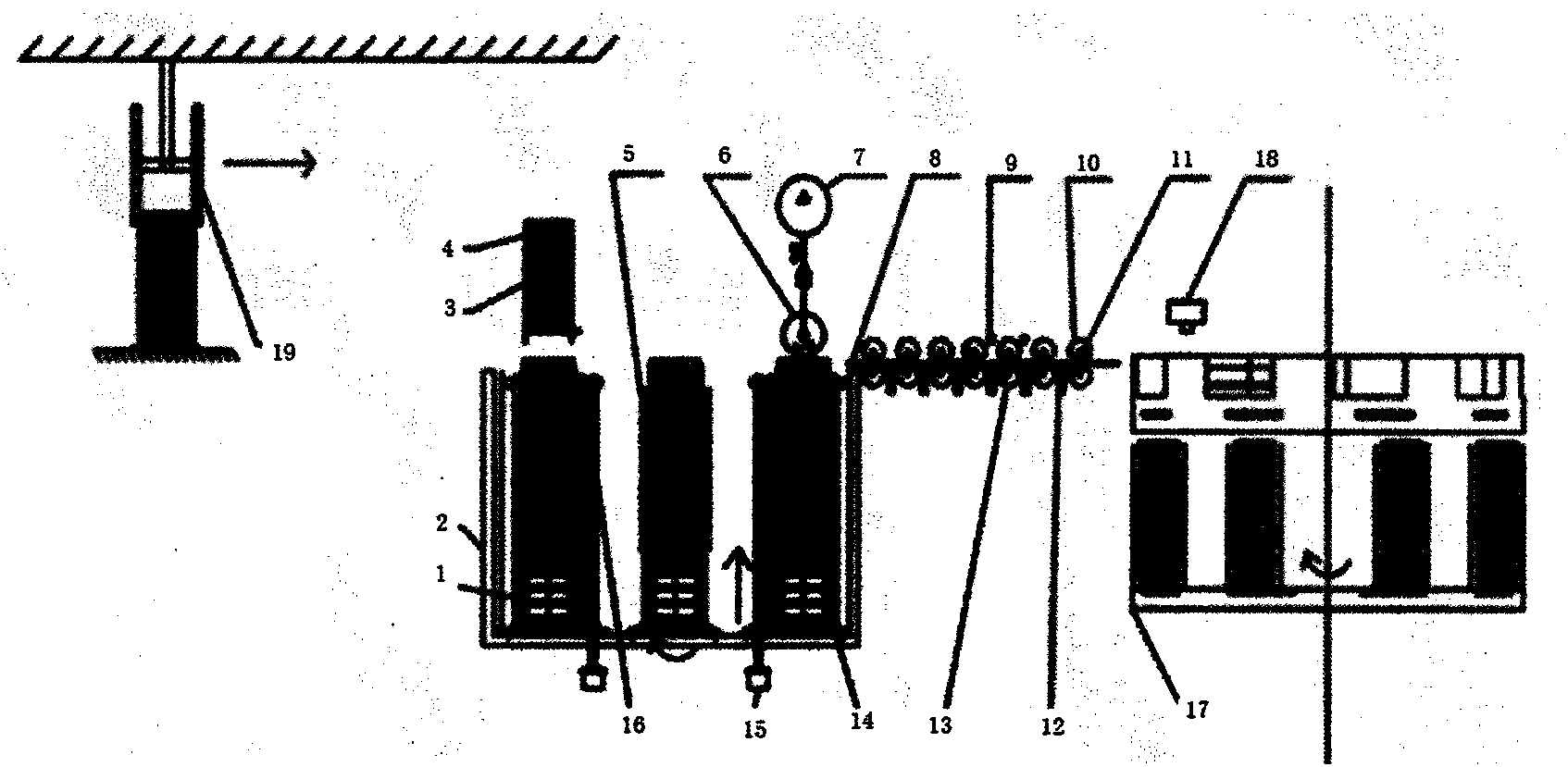

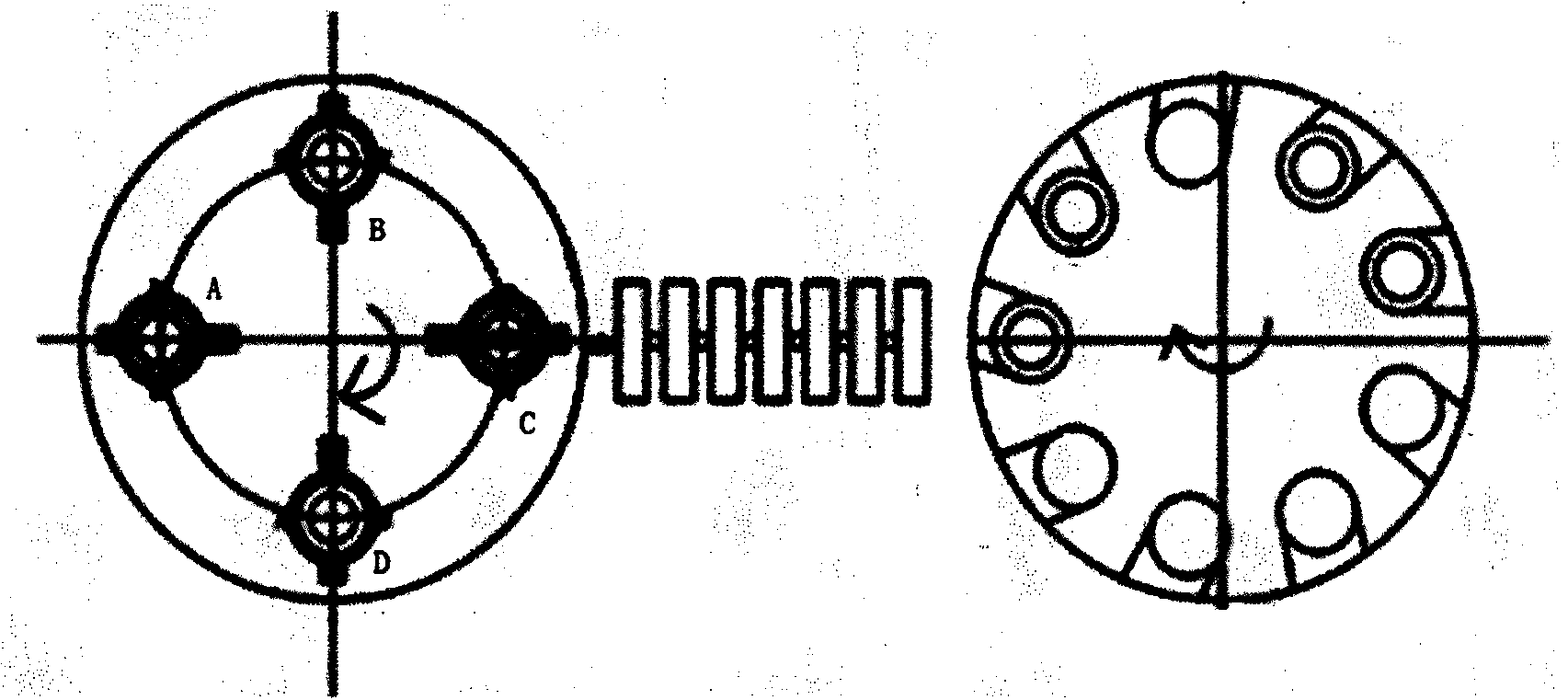

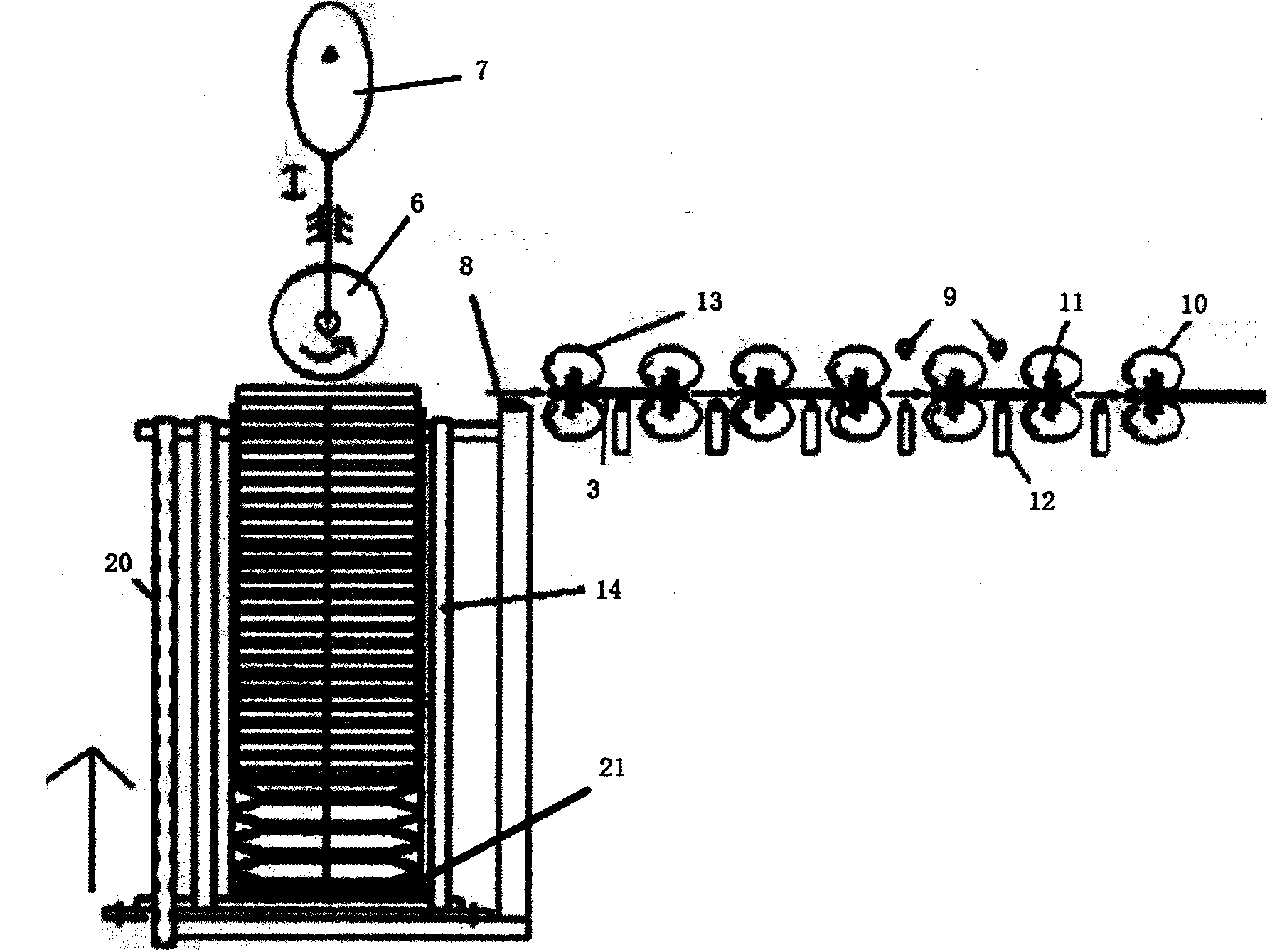

[0026] Such as figure 1 and figure 2 As shown, a composite material mesh intelligent sorting machine provided by the present invention includes a blanking cylinder 4 with a cover, a flip-type manipulator feeding subsystem, a multi-station turntable discharging subsystem, and a multi-sensor roller conveying subsystem , image processing and sorting subsystem and quality analysis and decision support subsystem.

[0027] After manually putting the composite material mesh sheet 3 into the blanking tube 4 in the manner of stacking up and down, the blanking tube 4 is closed with a cover.

[0028] The flipping manipulator feeding subsystem includes a clamping mechanism 19 and a pallet that can move up and down. The blanking cylinder 4 equipped with the composite material mesh 3 is placed on the pallet, and the blanking cylinder 4 is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com