Material-receiving device for squeezing production

A material receiving device and extruder technology, which is applied in metal extrusion, metal extrusion control equipment, ceramic molding machines, etc., can solve problems such as poor appearance quality, changes in external dimensions, internal cracks in products, etc., and achieve processing speed Fast, fast response, smooth running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0018] The embodiment of the present invention is a material receiving device for extruding and producing cemented carbide rods with a diameter below ¢2mm.

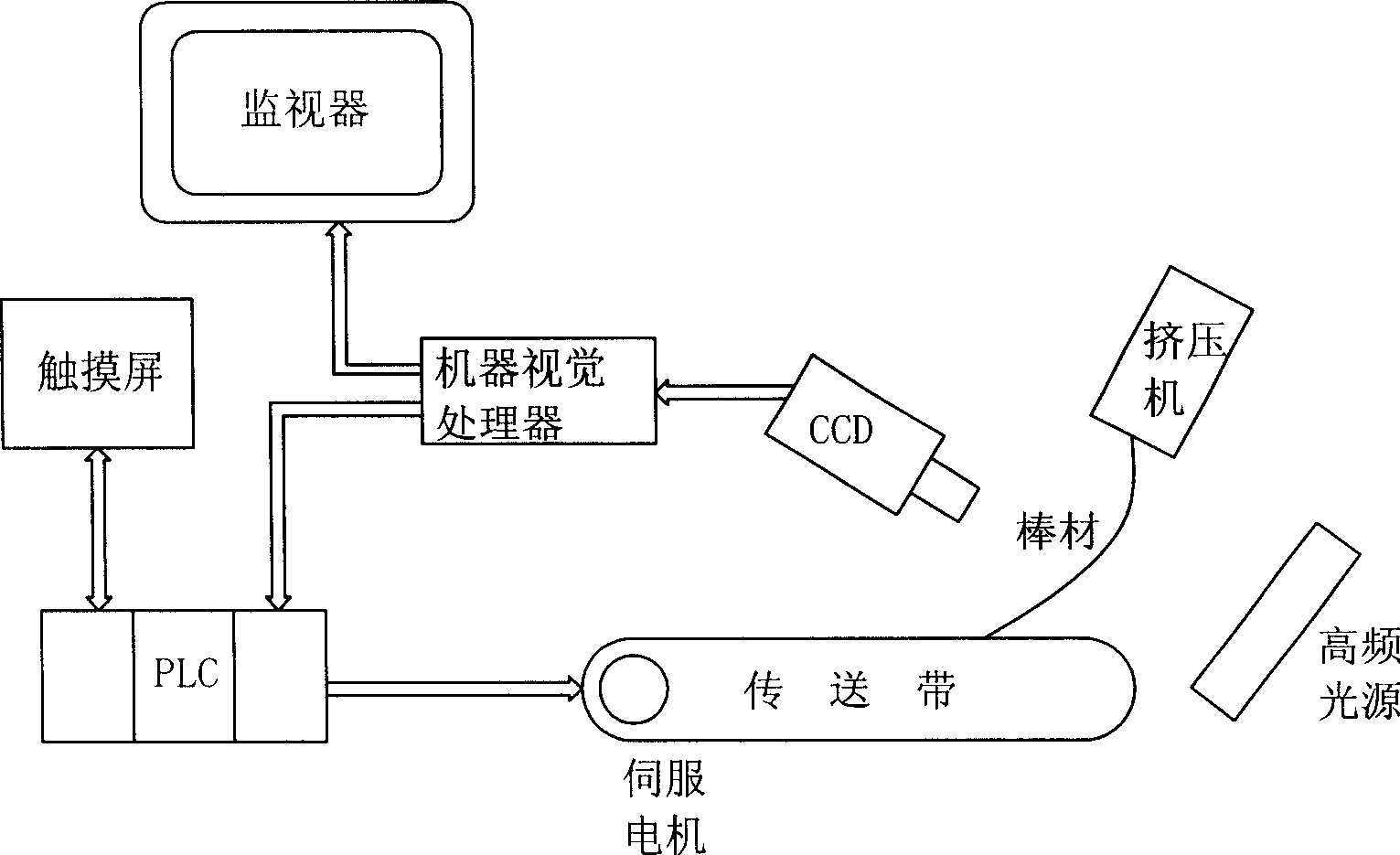

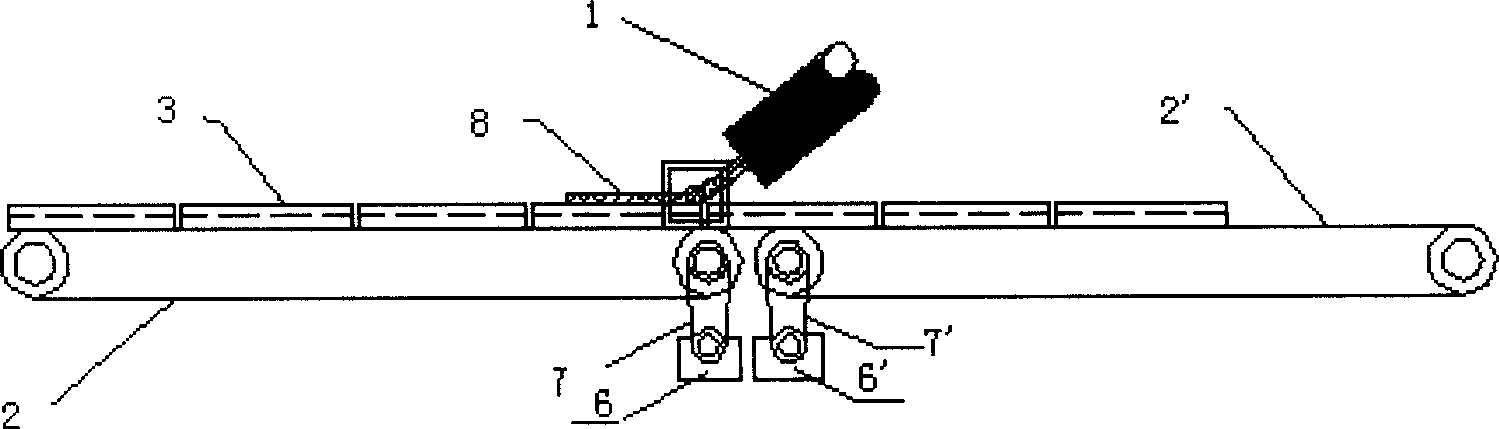

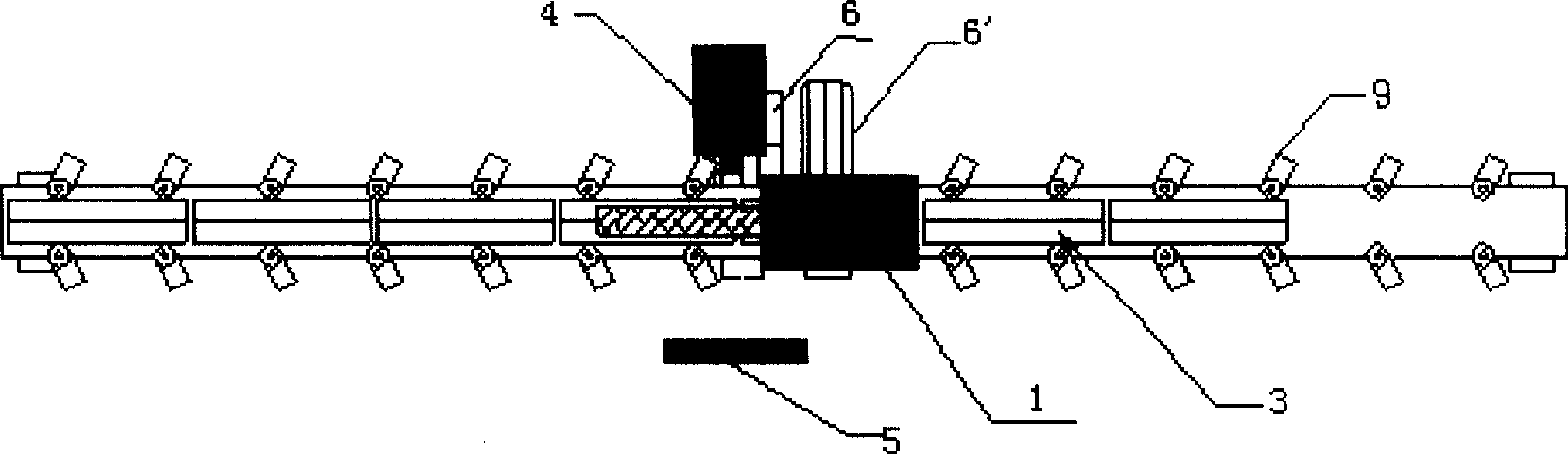

[0019] The material receiving device for extrusion production of the present invention includes a CCD camera 4 that takes pictures frame by frame of the bar stock 8 extruded by the extrusion head 1 of the extrusion machine, provides a high-frequency light source 5 of background light for the CCD camera 4, and receives the CCD camera 4. The machine vision image processor that takes photos and performs digital processing, receives the data from the machine vision image processor through the serial bus, and can analyze and judge the extruded product form. The PLC host that issues speed control instructions, according to The servo motor 6 that receives the PLC host speed control command actio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com