Measurement method for verticality of optical axis of microscope system

A microscopic system and measurement method technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of large errors, simplicity, roughness, etc., and achieve the effects of good feasibility, accurate positioning, and simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Determine the inclined plane of the optical axis

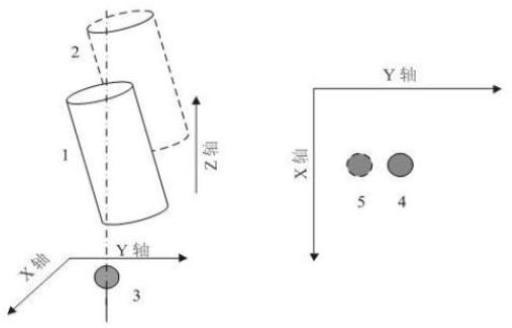

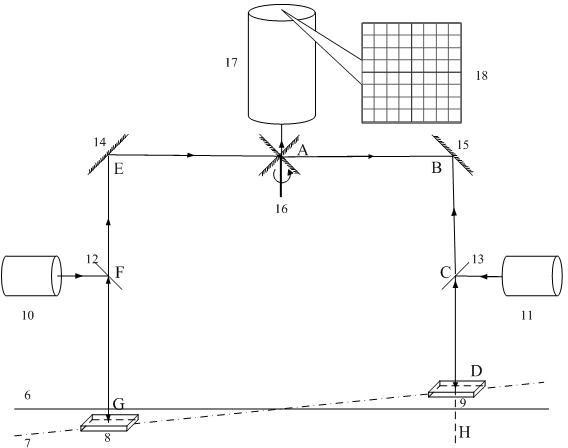

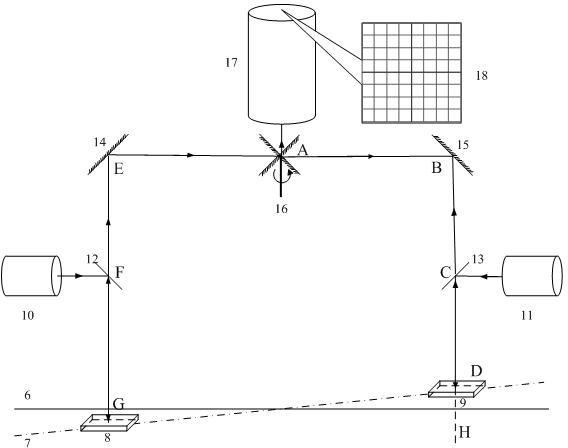

[0035] To measure the verticality of the optical axis with the optical path extension arm method, firstly, determine the direction in which the optical axis of the microscope system is tilted, so as to determine the placement direction of the calibration plate. Such as figure 1 , in order to accurately obtain the inclined surface of the optical axis, the specific method is: use a 1mm standard sphere 3 (the standard for selecting the size of the standard sphere is that the center of the sphere imaged by it in the microscopic system cannot exceed the field of view) as the measured object in the microscopic system 1 Imaging, adjust the standard sphere so that the center of the sphere is imaged at the center of the field of view, and use a motor drive device to drive the lens to move in parallel in a straight line perpendicular to the object plane. In this embodiment, the motor drives the microscope lens to move away fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com