Precise positioning method for circular object with thickness interference

A positioning method and precise positioning technology, applied in the directions of instruments, character and pattern recognition, computer parts, etc., can solve the problem of large rotation angle error, and achieve real-time detection, accurate detection and precise positioning, and high positioning accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention is further described below in conjunction with the accompanying drawings, but the scope of the present invention is not limited in any way.

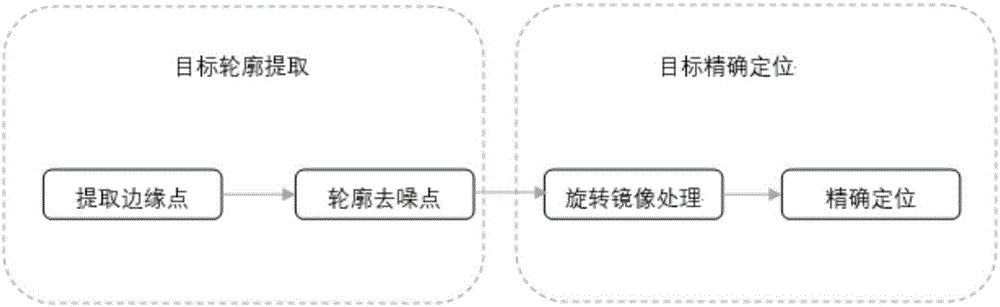

[0047] 1. Operation process

[0048] Such as figure 1 As shown, the framework of the present invention can be divided into three parts: contour extraction of noise-removing points, processing of rotating mirror images, and precise positioning. In the stage of contour extraction of noise-removing points, thickness noise is removed by calculating the density of edge points. Based on the judgment of the position relationship between the center of the noise point and the major axis of the ellipse detected by the Hough transform detection, the target precise positioning part uses the detected ellipse information to perform precise target positioning through the precise positioning algorithm.

[0049] Second, the specific implementation process

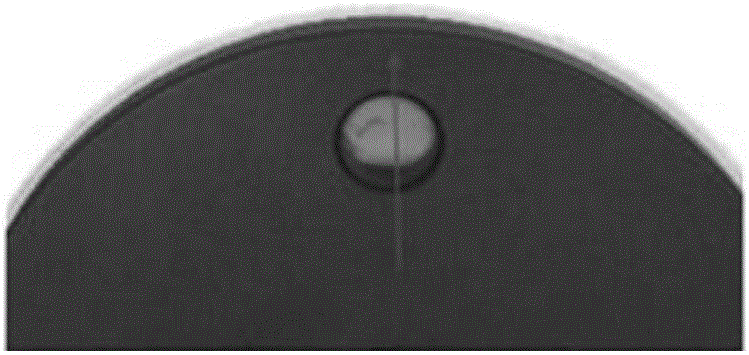

[0050] The precise detection and positioning method of a circular o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com