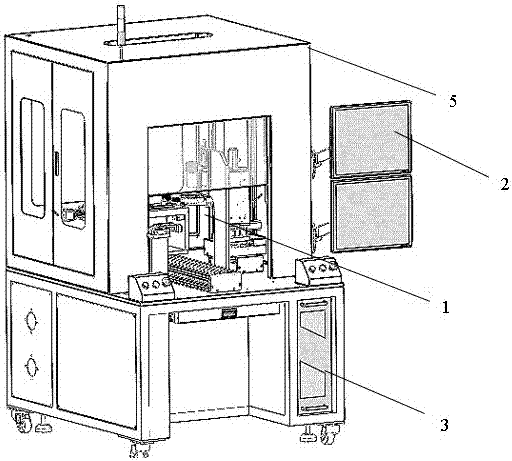

Automatic laser welding device with CCD vision detection function and welding method

A laser welding and laser technology, applied in the field of automatic laser welding equipment, can solve the problems of low efficiency, poor welding quality, poor positioning effect of welding head, etc., and achieve the effect of easy adjustment of positioning, improvement of welding efficiency, and improvement of positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

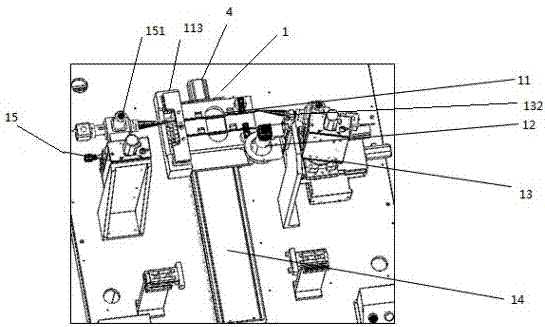

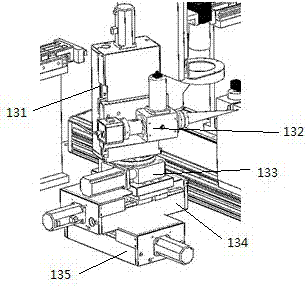

[0030] The product 111 fixture 11 is arranged on the feeding shaft 14, and its function is to fix and clamp the product 111 to be welded, and the feeding method is manual loading and unloading directly.

[0031] The rotary compression cylinder 112 is used to compress the product 111 to be welded after the loading of the product 111 to be welded is completed, so as to reduce the impact of the vibration caused during the movement on the welding machine.

[0032] The positioning datum 113 with guide rail is used to keep the positioning of the left side of the product to be welded relatively consistent each time the material is loaded.

[0033] The function of the feeding shaft 14 is to transport the product 111 fixture 11 to the position of the industrial camera 12 at a stable and uniform speed to take pictures and deliver the photographed information to the industrial control system 3 for calculation and processing. After completion, the product 111 is further sent to the four-di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com