Plate-fin heat exchanger fin machining quality online inspection method based on machine vision

A technology of plate-fin heat exchanger and machine vision, applied in the direction of neural learning methods, instruments, measuring devices, etc., can solve the problems of expensive equipment, not supporting online inspection of fin processing quality, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is further analyzed below in conjunction with specific examples.

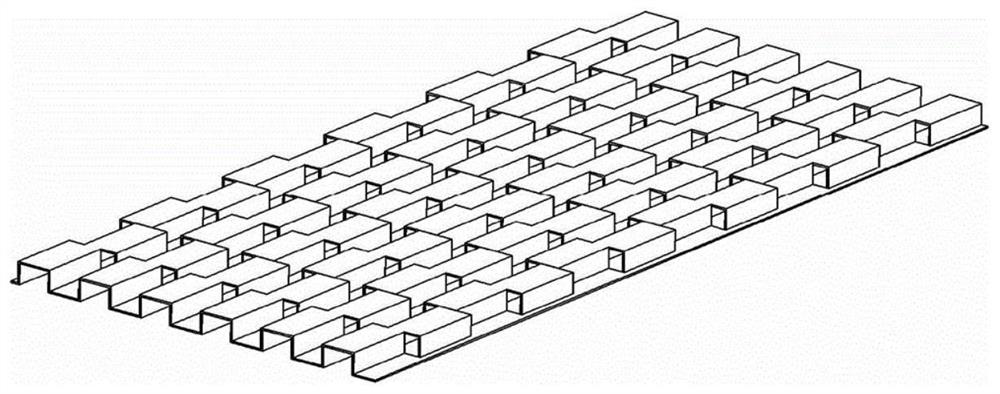

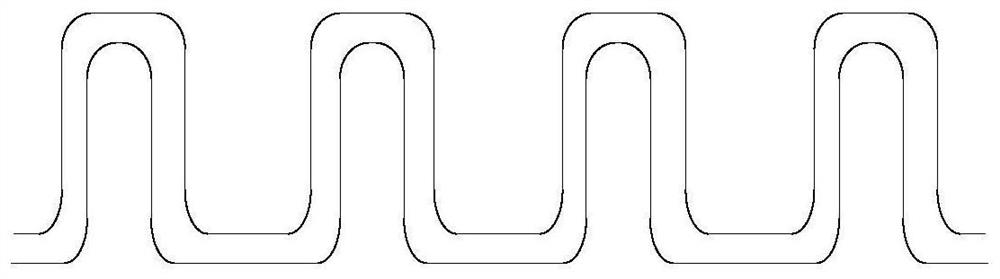

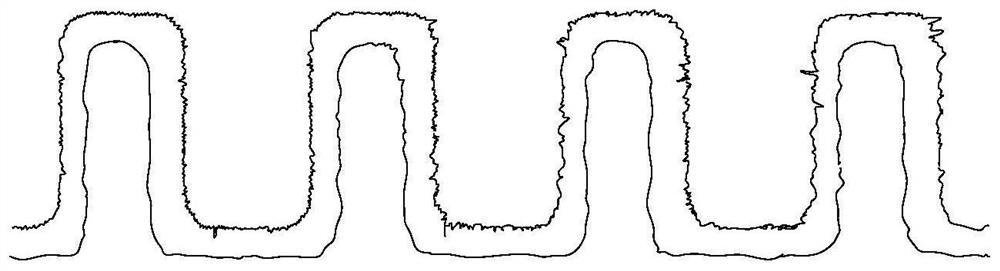

[0038] figure 1 Schematic diagram of the structure of the plate-fin heat exchanger; figure 2 is the burr-free fin cutout image; image 3 Cutout image for fin with burrs.

[0039] Such as Figure 4 The online inspection method of fin processing quality of plate-fin heat exchanger based on machine vision, specifically includes the following steps:

[0040] Step (1), obtaining the grayscale image of the fin incision;

[0041] The grayscale image of the fin incision was obtained by using LED light source and industrial high-definition image sensor (CCD).

[0042] Step (2), preprocessing of the grayscale image of the fin incision:

[0043] 2.1 Due to the reflection of the fin incision image acquired under the LED light source, some points are relatively bright, which may drown important information. In order to improve the flexibility and accuracy of recognition, the grayscale ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com