Coupling focal length press machine

A press and focal length technology, applied in the field of optical communication, can solve the problems of poor crimping accuracy, poor precision, poor crimping accuracy, etc., and achieve the effects of stable optical signal indicators, high pressing efficiency and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

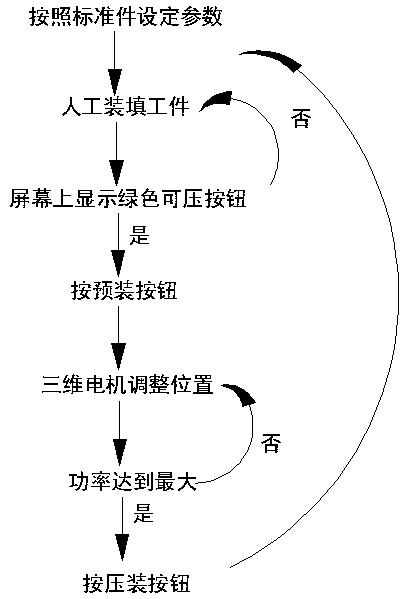

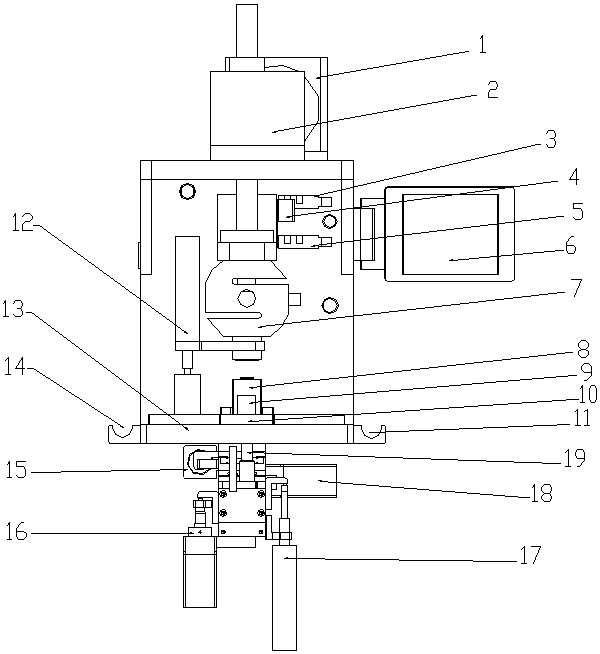

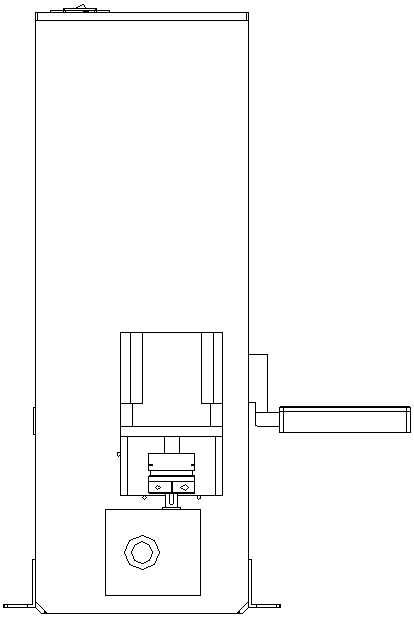

[0017] Such as figure 1 , figure 2 , image 3 As shown, a coupling focal length press includes an inner hollow shell, on which a first stepping motor 2 is arranged, and the first stepping motor 2 is connected with a spiral lifting rod 1, and one end of the spiral lifting rod 1 is arranged on In the housing, a limit switch, a pressure sensor 7 and a grating ruler 12 are arranged in the housing, and the limit switch, the pressure sensor 7 and the grating ruler 12 are all fixed on the part where the spiral lifting rod 1 is arranged in the housing, and the pressure sensor 7 is arranged on Below the limit switch, the connection between the grating ruler 12 and the spiral lifting rod 1 is located below the pressure sensor 7, and a grooved workbench 10 and a console 13 are installed in the housing, and the grooved workbench 10 and the console 13 are both arranged on the Below the pressure sensor 7, an indenter 9 and a tooling 8 are arranged above the trough workbench 10, the tooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com