Novel intelligent vibration device of full-automatic block making machine for bulk solid waste

A block forming machine and vibration device technology, which is applied to ceramic forming machines, fluids using vibration, manufacturing tools, etc., can solve the problems of consuming kinetic energy, affecting production efficiency, and insufficient excitation force, so as to reduce the vibration force energy consumption, highlighting the substantive features, and improving the vibration acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

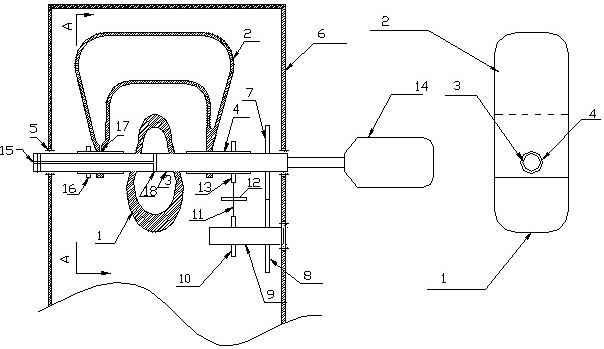

[0018] A new type of intelligent vibration device for the bulk solid waste automatic block forming machine. The device consists of an eccentric (1), an automatic coupling counterweight (2), a transmission main shaft (3), a transmission main shaft sleeve (4), a transmission main shaft bearing (5), a vibrator outer shell (6), and a driving gear (7 ), driven gear (8), gear shaft (9), transmission gear (10), crank pull rod (11), crank shaft (12), drive shaft sleeve drive wheel (13), motor (14), eccentric The oil inlet and outlet device (15), the automatic coupling counterweight body oil inlet and outlet device (16), the automatic coupling counterweight body oil inlet and outlet hole (17) and the eccentric element oil inlet and outlet hole (18) are formed.

[0019] The eccentric (1) is bar-shaped in shape and hollow inside, and is connected and fixed with the transmission main shaft (3), and rotates with the rotation of the transmission main shaft (3), and the other end of the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com