Miniature calorimeter

A micro calorimeter, mass flow technology, applied in the direction of material thermal development, etc., can solve problems such as quantitative analysis of difficult materials, inability to simulate fire combustion behavior, combustion test methods that cannot fully describe combustion performance, etc., achieving low cost and easy operation. , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described below in conjunction with accompanying drawing.

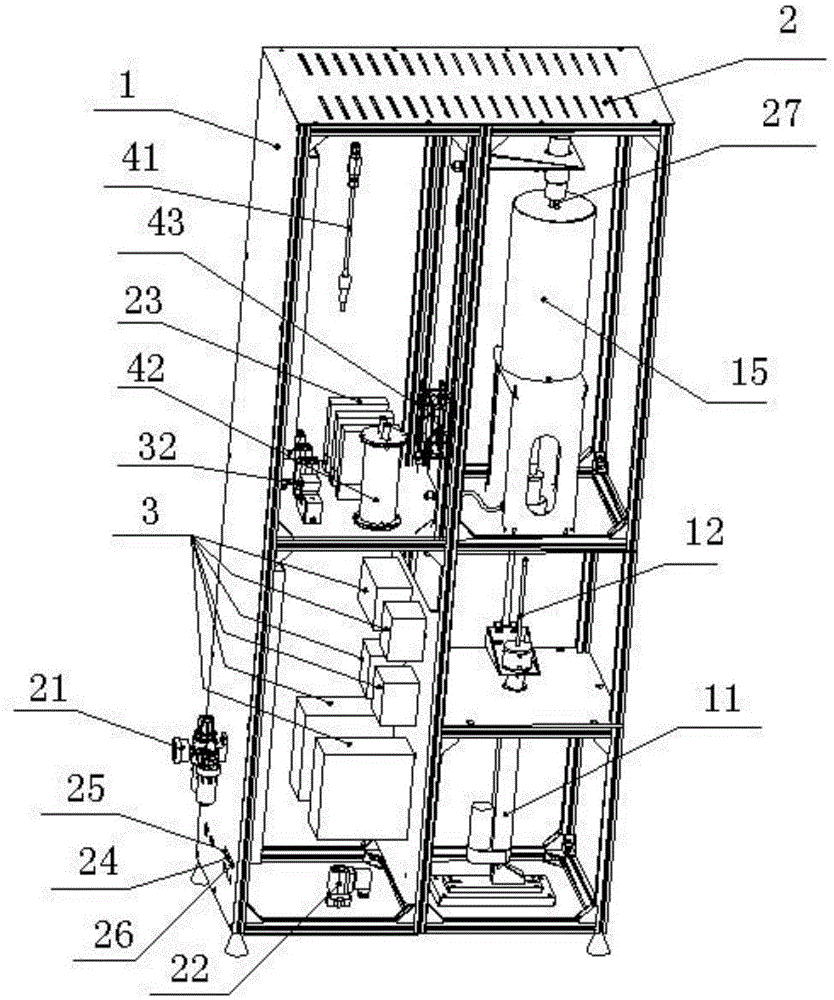

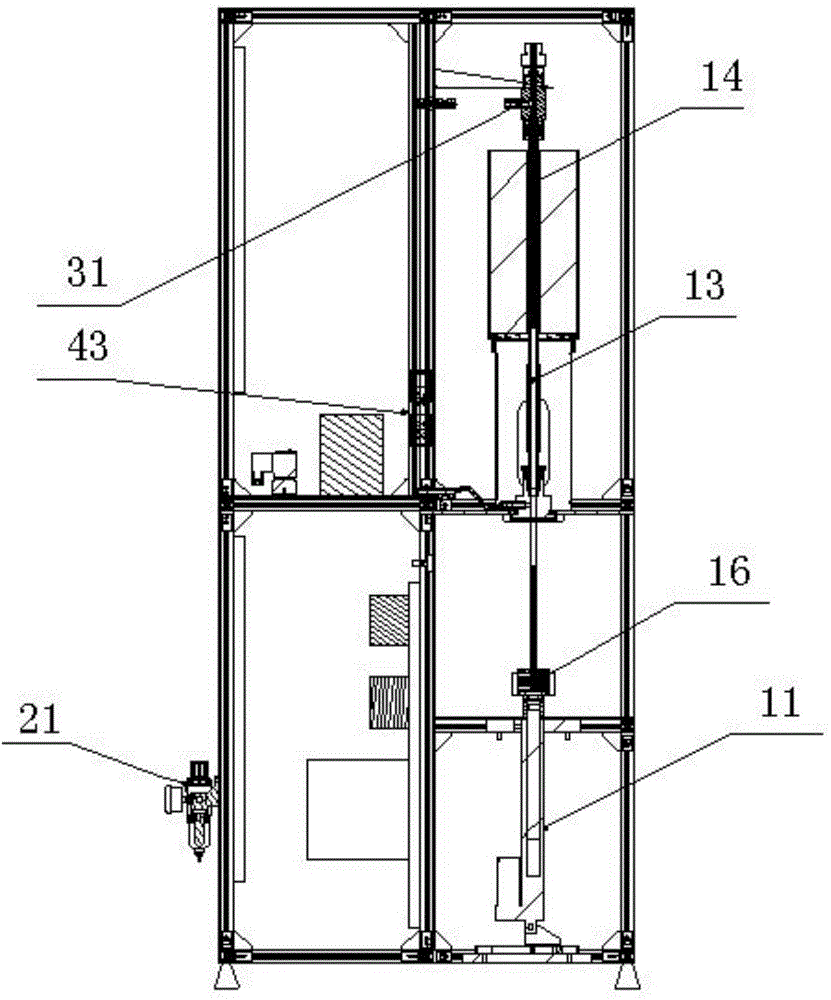

[0015] as attached Figure 1-2 As shown, a kind of miniature calorimeter described in the present invention comprises frame 1, and sample component, intake circuit, exhaust circuit and control system are arranged on frame 1, and the top of frame 1 is provided with multiple groups Heat dissipation holes 2; the sample assembly includes a sample delivery electric cylinder 11, a support rod 12, a decomposition chamber 13 and a combustion chamber 14; the decomposition chamber 13 and the combustion chamber 14 are provided with a heating furnace 15; the heating furnace 15 is divided into two One section corresponds to the decomposition chamber 13, and one section corresponds to the combustion chamber 14; the support rod 12, the decomposition chamber 13, the combustion chamber 14 and the two-stage heating furnace 15 are all provided with temperature sensors, and the temperature sensors of this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com