Crude oil produced hydrogen sulfide on-line monitoring experimental device

The technology of an experimental device and a monitoring device, which is applied in measuring devices, chemical method analysis, instruments, etc., can solve the problems of time-consuming and labor-intensive, high risk factor, and less data recording, so as to avoid direct contact, simple operation procedures, The effect of a small risk factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

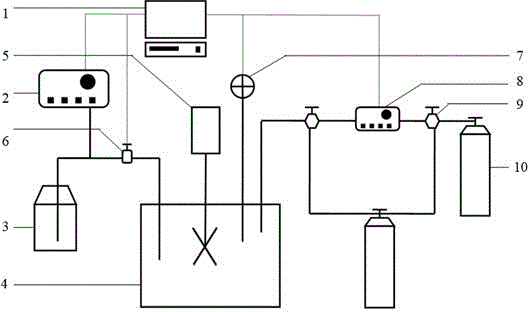

[0019] Such as figure 1 As shown in the experimental device for on-line monitoring of hydrogen sulfide produced by crude oil, the main high-pressure gas cylinder 10 is connected with a gas flow controller 8 to control the flow of gas entering the high-temperature and high-pressure reactor 4 . A pressure reducing valve is installed at the front and back of the gas flow controller, which is powered by the auxiliary high-pressure gas cylinder to control the stability of the pressure difference between the front and back of the gas flow controller. A stirrer 5 and a temperature and pressure sensor 7 are arranged in the reactor. A quick-opening valve 6 is connected to the back of the reactor, and the quick-opening valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com