Digital adjustable damping handle device and zero point positioning method therefor

A technology of zero point positioning and damping adjustment, which is applied in mechanical control devices, control/regulation systems, instruments, etc., can solve the problems of low control precision, short device life, and inability to adjust the operating force, achieving high control precision, simple structure, The effect of no transmission error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

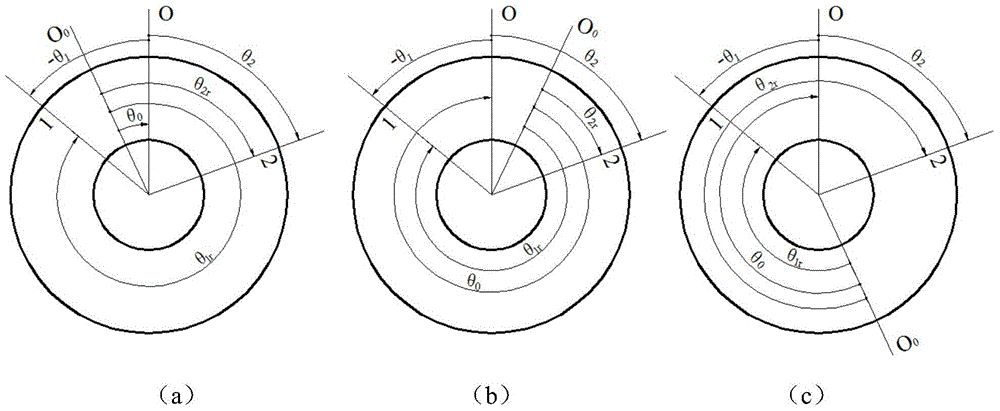

[0068] For the special heavy-duty machinery giant forging hydraulic press, the control angle is input through the operating handle, and the gear shaft on the corresponding distributor is controlled to rotate to the corresponding angle. The angle of the encoder on the handle device and the gear shaft device is compared to form a closed-loop control, so that the angle of the gear shaft is consistent with the angle of the handle.

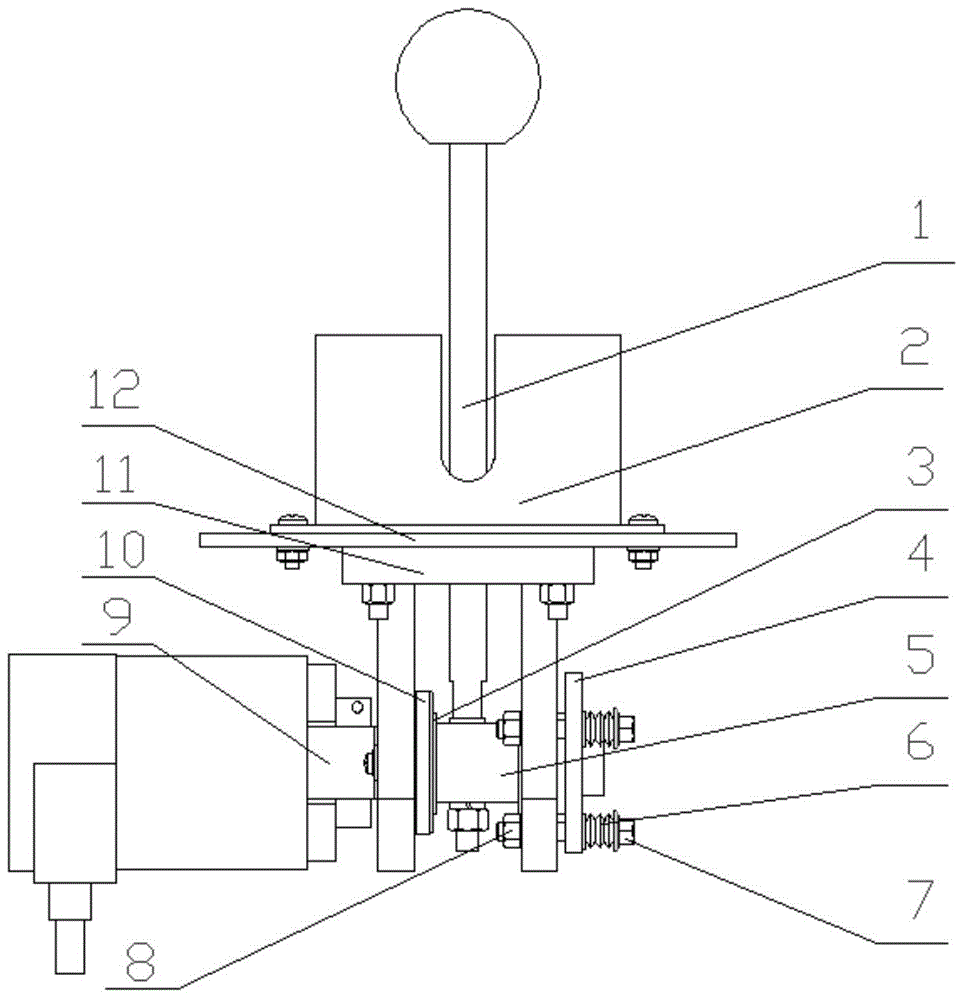

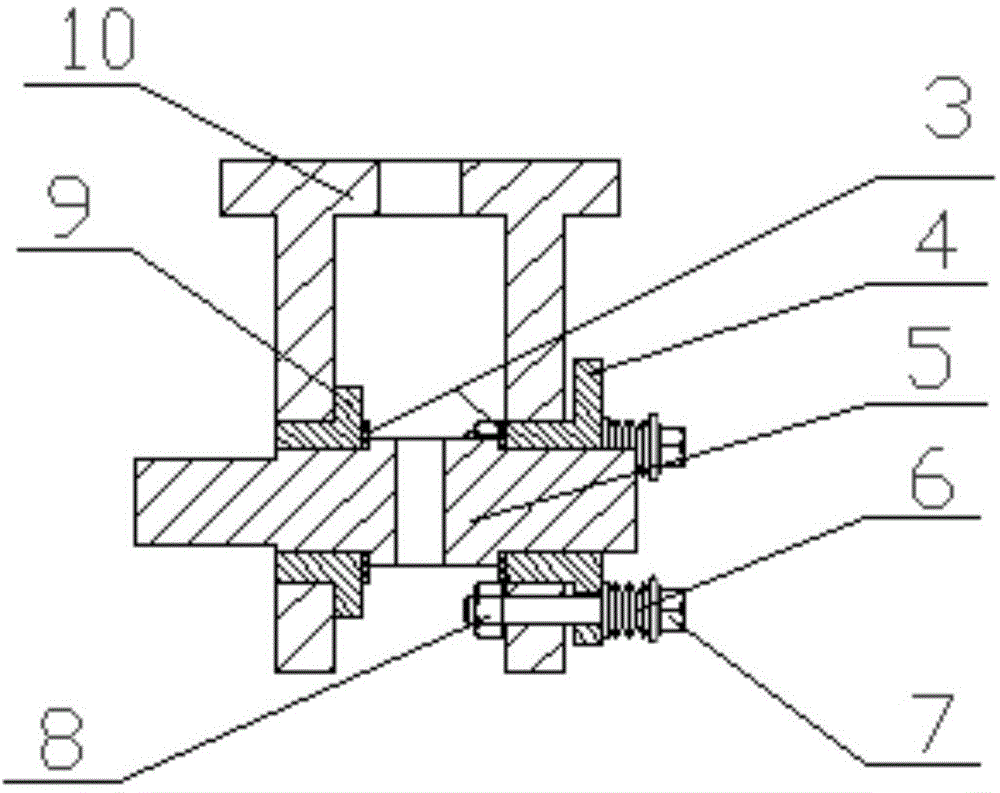

[0069] Such as figure 1 with figure 2 Describes the structure of a digital adjustable damping control handle device, which includes a bracket 10, a scale cover 2, a rotating shaft 5, a handle rod 1, a left sleeve 10, a right sleeve 4, a butterfly spring 6, and a friction ring 3. Rotary encoder 9 and operating platform 12;

[0070] The scale cover is used to limit the operating angle, and at the same time, installing a label on the scale cover can prompt the operator to push the handle to a certain position to indicate what operation instruction;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com