Dynamic displacement monitoring system for equipment chamber base plate of underground coal preparation plant

A technology of dynamic monitoring and equipment tunnels, applied in signal transmission systems, electrical signal transmission systems, non-electrical signal transmission systems, etc., can solve the problems of high accident rate, easy damage, large volume, etc., and achieve resistance to harsh industrial environments and reliable High performance and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

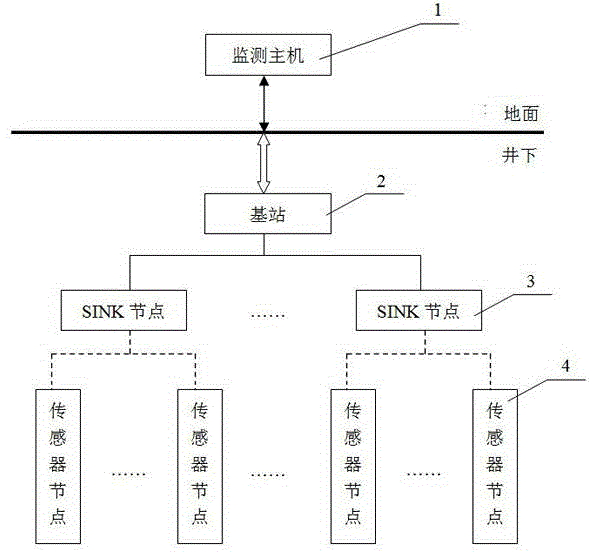

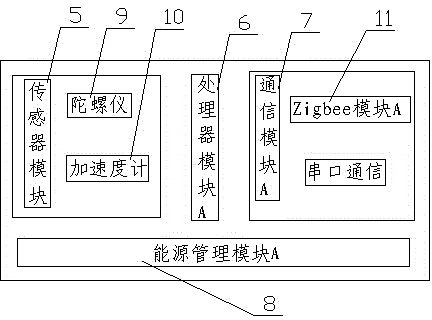

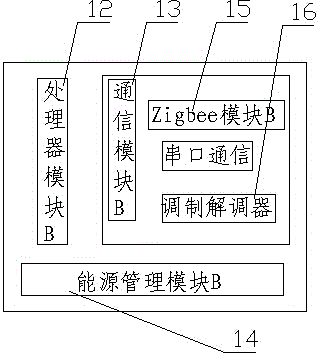

[0039] Such as Figure 1 to Figure 6 Shown: the present invention provides a kind of underground coal preparation plant equipment chamber floor displacement dynamic monitoring system, including sensor node 4, SINK node 3, base station 2 and monitoring host computer 1, described sensor node 4, SINK node 3 and base station 2 They are all arranged underground, the monitoring host 1 is arranged on the well, the sensor node 4 and the SINK node 3 are wirelessly connected, and the SINK node 3, the base station 2 and the monitoring host 1 are connected via wired connection. The sensor node is to monitor the displacement of the bottom plate in the equipment chamber of the underground coal preparation plant, and send the monitored data to the SINK node. Because the number of underground chambers is large and the situation in the mine is more complicated, SINK is adopted. The node performs data reception and command control on the sensor nodes in a certain area, and the SINK node is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com