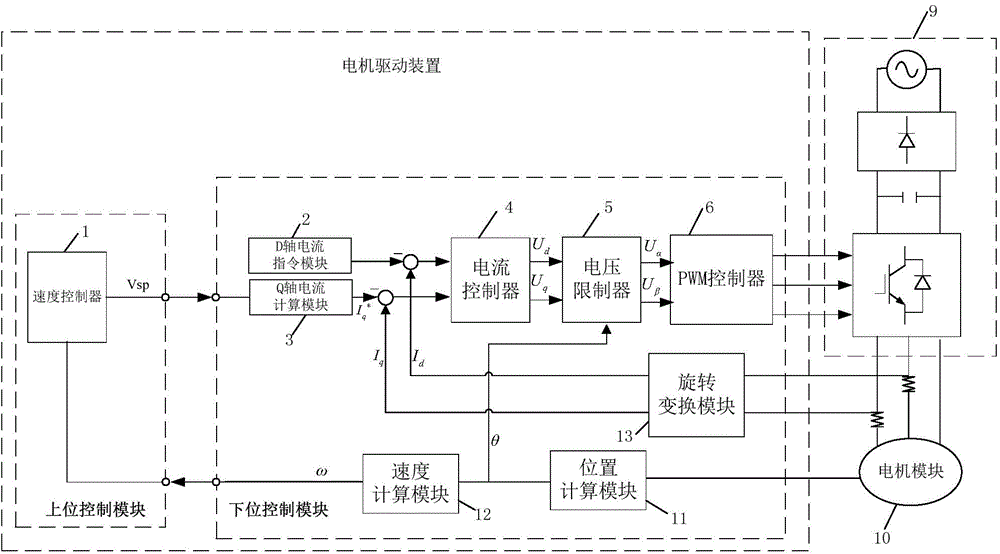

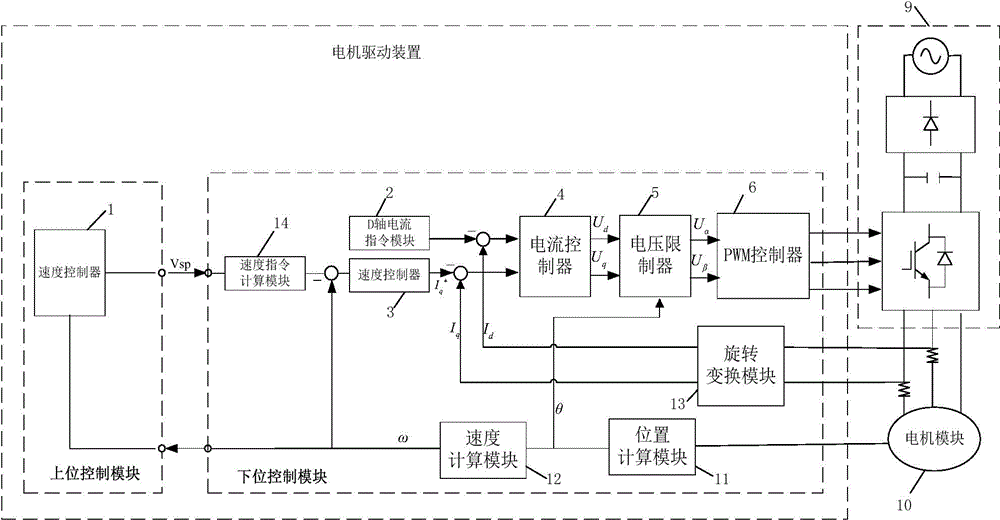

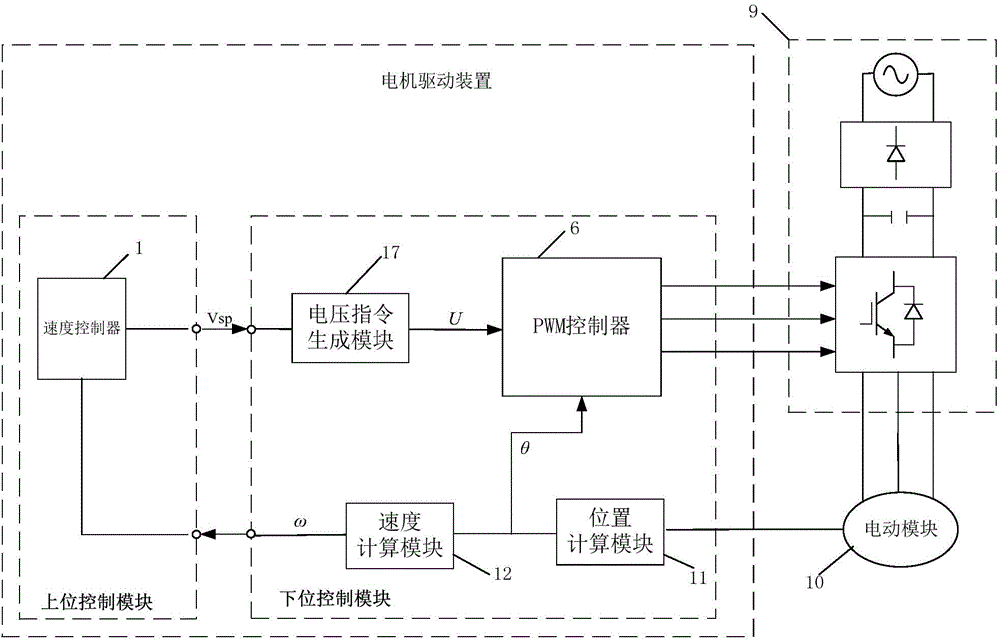

Motor drive device, motor drive method and motor

A technology of motor drive and motor rotor, which is used in the control of electromechanical transmission, control of generators, motor-generator control, etc., can solve the problems of poor resistance to load disturbance, large torque ripple, and uncontrollable current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0120] Further, as Figure 5 As shown, an implementation of the voltage limiter 5 outputting the direct-axis voltage and the quadrature-axis voltage after voltage limiting is as follows:

[0121] The voltage limiter 5 performs voltage limiting on the direct-axis voltage component and the preset quadrature-axis voltage component according to the limiting voltage, and then performs coordinate transformation according to the position feedback signal to output the direct-axis voltage and the quadrature-axis voltage.

[0122] Another implementation of the voltage limiter 5 outputting the direct-axis voltage and the quadrature-axis voltage after voltage limiting is as follows:

[0123] The voltage limiter 5 performs the coordinate transformation according to the position feedback signal, and then performs voltage limiting on the direct-axis voltage component and the preset quadrature-axis voltage component according to the limiting voltage to output the direct-axis voltage and the q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com