Assembling machine for automatically hanging pull tabs on the elephant trunk

A technology of elephant nose and assembly machine, which is applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problems of low assembly yield and low quality of finished products of zipper assembly machine, so as to save deburring process and improve quality , The effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

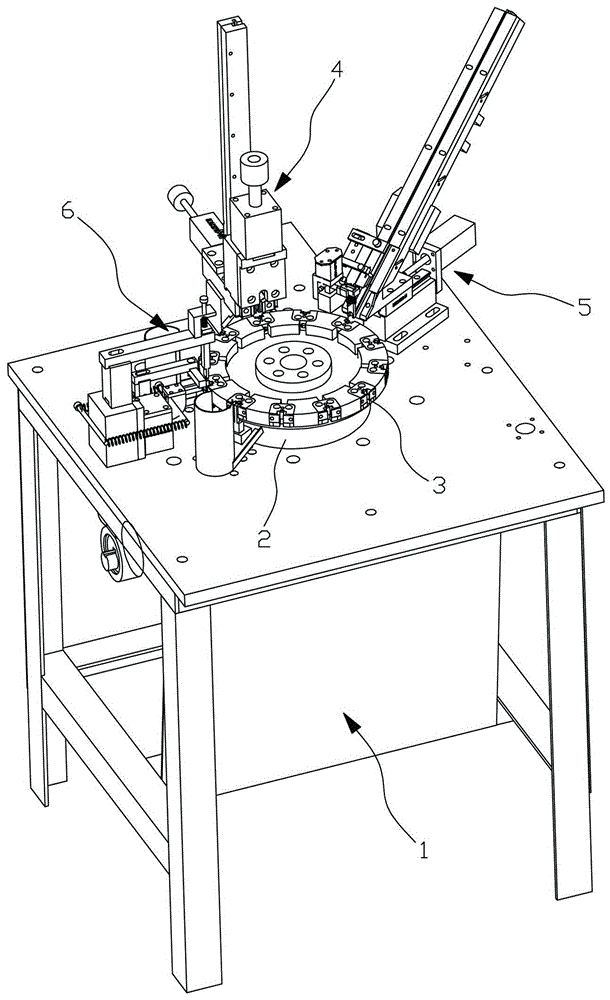

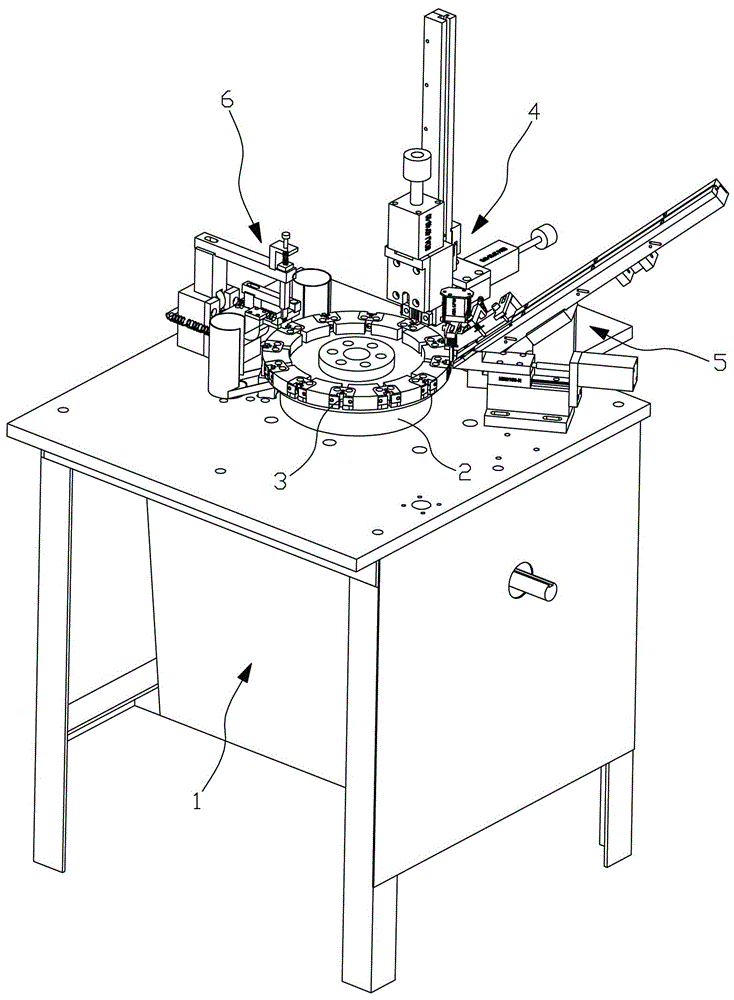

[0035] refer to figure 1 and figure 2 , an assembling machine for automatically hanging a pull tab on the trunk head, including a frame 1 and a circular turntable 2 arranged on the frame 1, and a plurality of slider die cores 3 are arranged on the circumferential surface of the circular turntable 2 at intervals. The frame 1 on the circumferential side of the circular turntable 2 is sequentially provided with a slider conveying device 4 , a pulling tab conveying device 5 and a riveting device 6 .

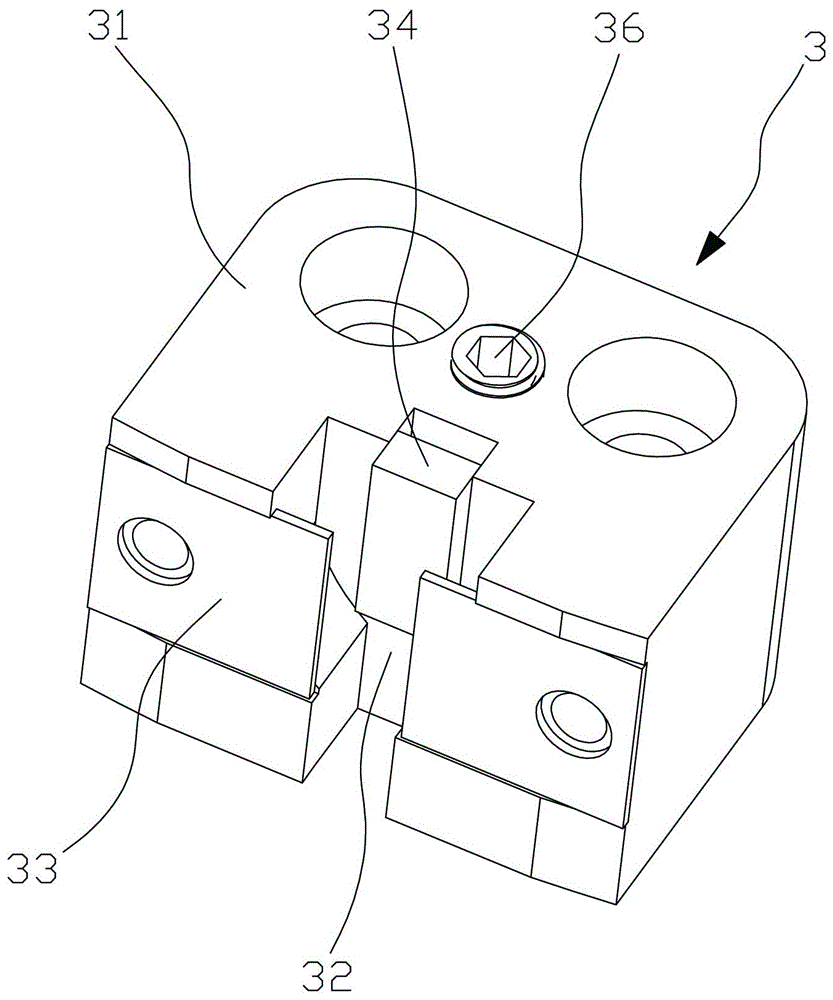

[0036]refer to image 3 and Figure 4 The above-mentioned slider mold core 3 includes a slider mold base 31, the slider mold base 31 is provided with a slider accommodating groove 32 with an opening at the front end, and two sides of the front end opening of the slider accommodating groove 32 are respectively provided with a sticker The vertical positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com