Printing and dyeing wastewater treatment device

A technology for treating equipment and printing and dyeing wastewater, applied in the fields of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of discount of precipitation treatment effect, long precipitation time, difficult to clean, etc., to achieve good pretreatment effect and environmental requirements Low, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

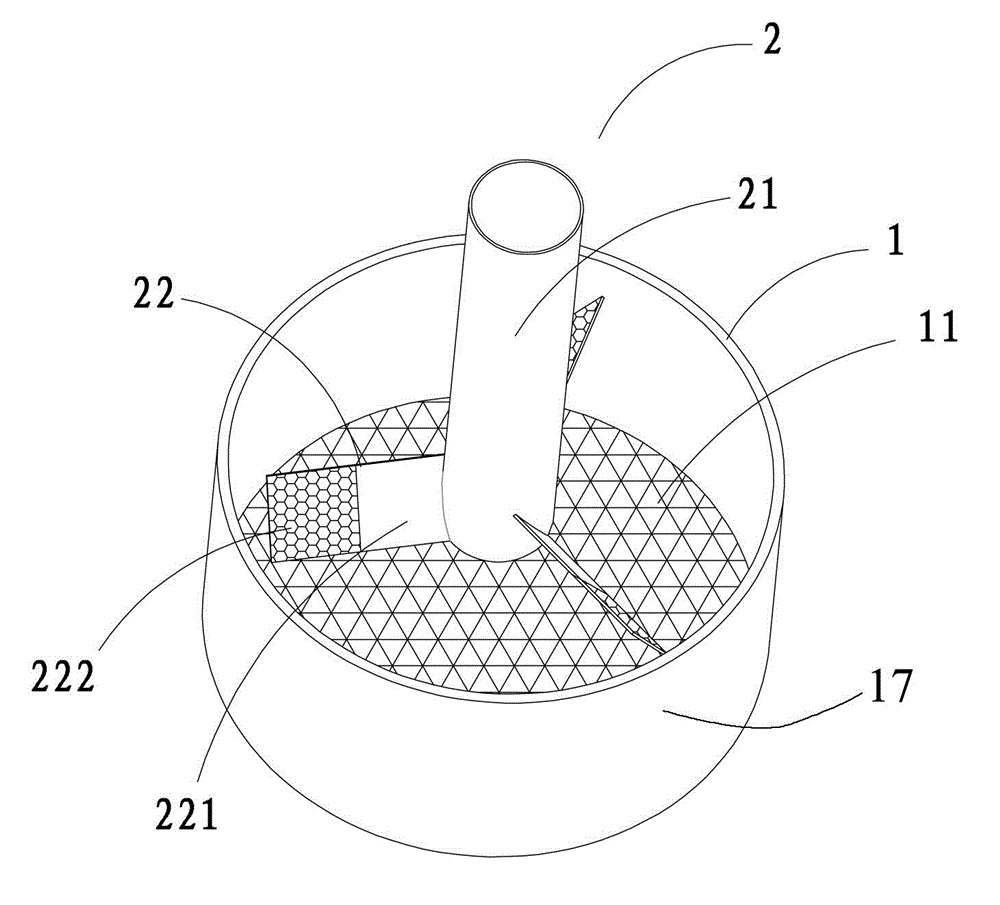

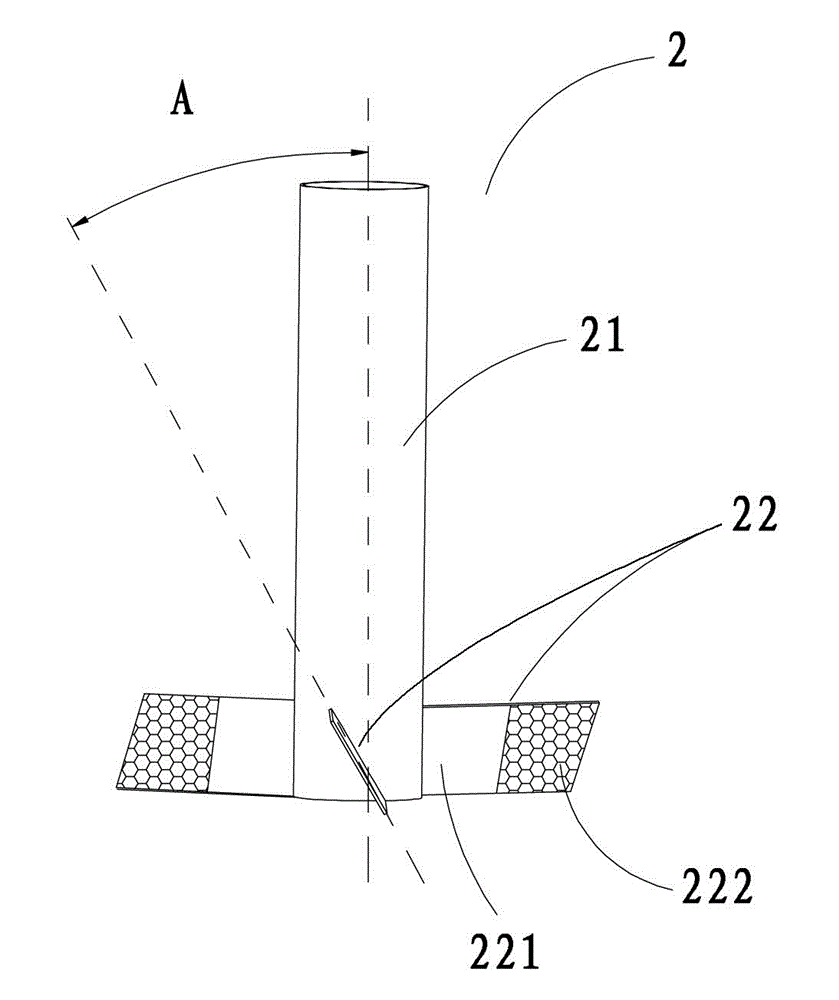

[0027] Such as figure 1 and 2 As shown, a kind of printing and dyeing wastewater treatment equipment includes a water filter tank 1 and a rotary filter mechanism 2, the bottom of the filter water tank 1 is provided with a bottom filter screen 11, and the rotary filter mechanism 2 includes a rotating shaft 21 and is fixedly connected to the The centrifugal filter blade 22 on the rotating shaft 21, the centrifugal filter blade 22 includes a solid sheet area 221 and a filter screen area 222, and the solid sheet area 221 is arranged on an end where the centrifugal filter blade 22 is connected to the rotating shaft 21, The filter screen area 222 is disposed at the end of the centrifugal filter blade 22 . The centrifugal filter blade 22 is arranged obliquely relative to the axial direction of the rotating shaft 21, and the angle A between the centrifugal filtering blade 22 and the rotating shaft 21 is 40°, that is, in the working state, the rotating shaft 21 It is arranged vertic...

Embodiment approach 2

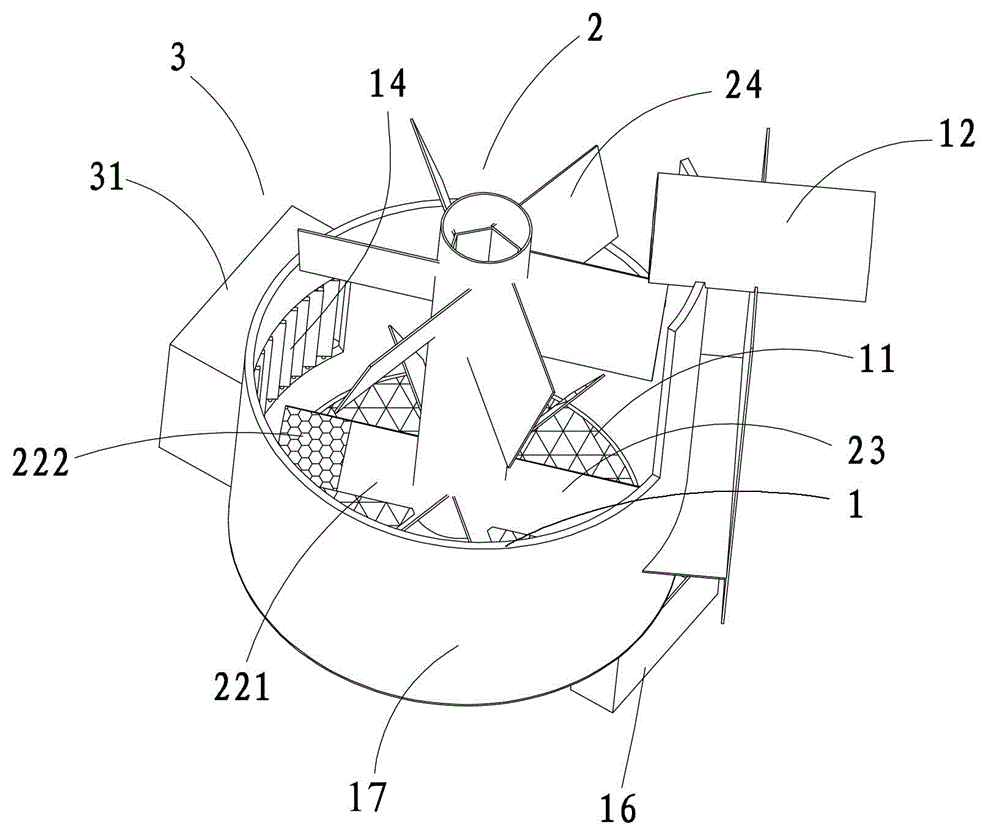

[0030] Such as Figures 3 to 7 As shown, a kind of printing and dyeing wastewater treatment equipment includes a water filter tank 1 and a rotary filter mechanism 2, the bottom of the filter water tank 1 is provided with a bottom filter screen 11, and the rotary filter mechanism 2 includes a rotating shaft 21 and is fixedly connected to the The centrifugal filter blade 22 on the rotating shaft 21, the centrifugal filter blade 22 includes a solid sheet area 221 and a filter screen area 222, and the solid sheet area 221 is arranged on an end where the centrifugal filter blade 22 is connected to the rotating shaft 21, The filter screen area 222 is disposed at the end of the centrifugal filter blade 22 . The centrifugal filter blade 22 is arranged obliquely relative to the axial direction of the rotating shaft 21, and the angle A between the centrifugal filtering blade 22 and the rotating shaft 21 is 40°, that is, in the working state, the rotating shaft 21 Set vertically to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com