Casting machinery waste gas treatment system

A technology for waste gas treatment and casting machinery, which is applied in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, etc. It can solve the problems of poor air quality, polluted indoor air, pollution, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

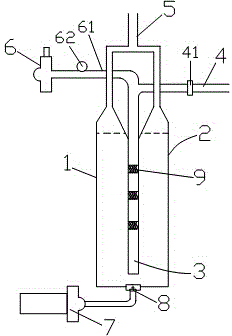

[0008] Such as figure 1 As shown, a waste gas treatment system for foundry machinery mainly includes two tanks, an inlet pipe 3, an air delivery pipe 4, an outlet pipe supervisor 5, a Roots pump 6 and a return pump 7, and the two tanks are tank-1 And the tank body two 2 adjacent bottoms are connected, the introduction pipe 3 is arranged between the tank body one 1 and the tank body two 2, the lower end nozzle communicates with the tank body bottom of the connecting body, the upper end of the introduction pipe 3 One side is connected with the air delivery pipe 4, and a pipe check valve 41 is installed on the air delivery pipe 4, and the other side is connected with the infusion tube 61, and the other end of the infusion tube 61 is connected with the Roots pump 6, and the infusion A flow meter 62 is installed on the pipe 61 , and an outlet pipe is respectively installed on the upper ends of the first tank body 1 and the second tank body 2 and converges on the main pipe 5 of an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com