Novel permanent magnetic iron removal machine

A permanent magnet and permanent magnet technology, applied in the field of new permanent magnet iron remover, can solve the problems of inconvenient daily maintenance, high use cost and high failure rate, and achieve low magnetic field demagnetization rate, low use cost and low failure rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

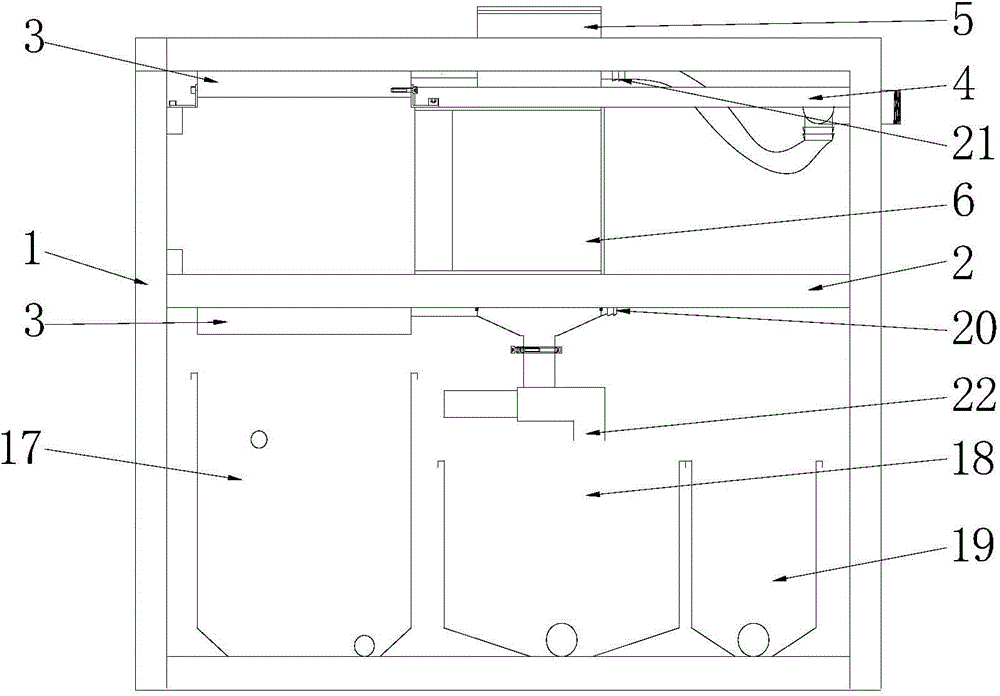

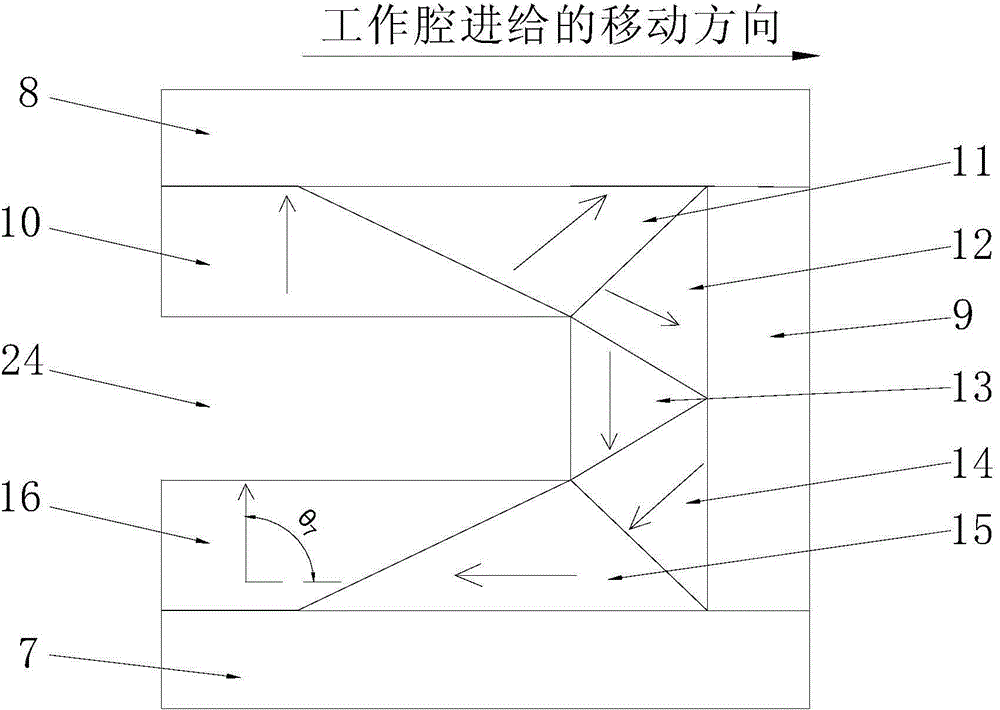

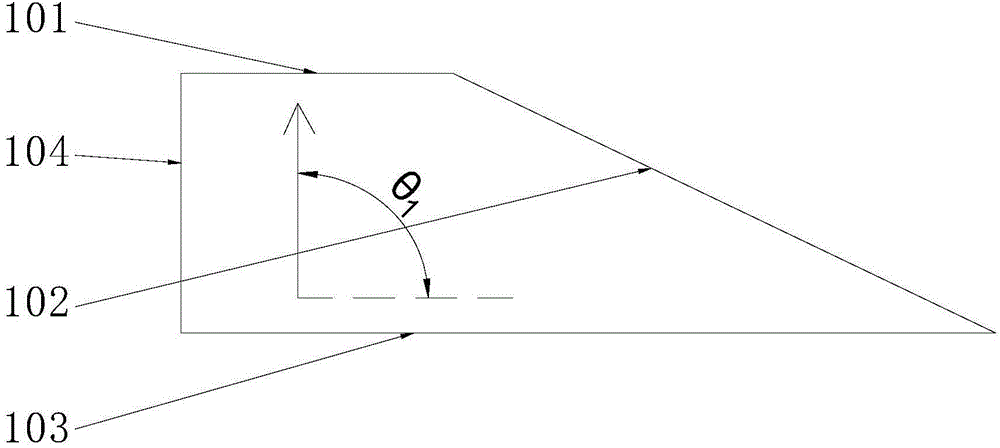

[0033] Such as figure 1In the shown iron remover, a fixed bracket 2 is installed on the frame 1, and a cylinder 3 as a translation device is fixed on the fixed bracket 2. The top of the frame 1 is also equipped with another cylinder 3 as a translation device, and the two cylinders 3 are parallel to each other. In addition, a linear guide rail 4 as a linear guide is installed on the frame 1 , and the linear guide rail 4 is arranged parallel to the moving direction of the piston rod of the cylinder 3 . A working chamber 5 is installed on the linear guide rail 4 , and the working chamber 5 is connected with the piston rods of the two cylinders 3 . Several soft magnetic rods as soft magnetic mesons are installed in the working cavity 5 . Several cleaning nozzles are installed on the top of the working chamber 5, and the cleaning nozzles can adopt the exi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com