ti 3 sic 2 ‑Co-based diamond ultra-thin saw blade material preparation method

A technology of ultra-thin and saw blades, which is applied in the direction of mechanical equipment, other manufacturing equipment/tools, turbines, etc., can solve the problems of restricting applications and shortening the service life of diamond ultra-thin saw blades, achieve high precision of composition control, and overcome high-speed cutting Performance, process stability and reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

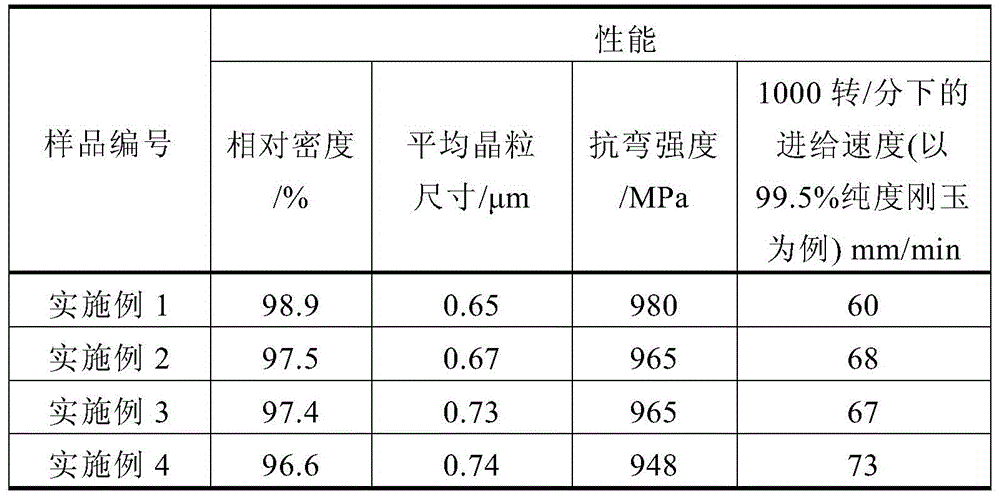

Examples

Embodiment 1

[0024] (1) First, pre-mix titanium powder, silicon powder, graphite powder and aluminum powder according to the molar mass ratio of 2.8:1.3:2.1:0.25 for 1.5 hours, then ball mill the pre-mixed powder for 14 hours under the protection of argon atmosphere, and the ball mill speed is 280 rpm, the ball milling medium is absolute ethanol, the balls and the ball milling tank are made of stainless steel, material: ball: absolute ethanol = 1:19:0.3; the ball mill powder is sintered under the protection of argon atmosphere, The sintering temperature is 1450°C, the holding time is 2 hours, the heating rate is 5°C / min, and the cooling rate is 16°C / min, to obtain Ti 3 SiC 2 powder.

[0025] (2) by mass percentage, take 87% Ti 3 SiC 2 , 9% Co, 4% MBD with an average particle size of 40 μm 8 Artificial diamond, ball milled under the protection of argon atmosphere for 30 hours, the speed of the ball mill is 160 rpm, the grinding balls are hard alloy balls, the material of the ball millin...

Embodiment 2

[0028] (1) Ti 3 SiC 2 Powder preparation is the same as in Example 1.

[0029] (2) By mass percentage, take 89.2% Ti 3 SiC 2 , 7% Co, 3.8% MBD with an average particle size of 40 μm 8 Artificial diamond was ball milled for 26 hours under the protection of an argon atmosphere, the ball mill speed was 180 rpm, and all the other process parameters were the same as in Example 1.

[0030] (3) Put the obtained mixed powder into a special mold for cold pressing, and the forming pressure is 100 MPa; under vacuum conditions, put the cold-pressed green body into a hot-pressing sintering furnace, sinter at 780 ° C, and keep it warm for 6 minutes. When cooling, the cooling rate is 25°C / min.

Embodiment 3

[0032] (1) Ti 3 SiC 2 Powder preparation is the same as in Example 1.

[0033] (2) By mass percentage, take 90% Ti 3 SiC 2 , 6.2% Co, 3.8% MBD with an average particle size of 40 μm 8 Artificial diamond was ball milled for at least 28 hours under the protection of an argon atmosphere, the ball mill speed was 150 rpm, and the remaining process parameters were the same as in Example 1.

[0034] (3) Put the obtained mixed powder into a special mold for cold pressing, and the forming pressure is 100MPa; under vacuum conditions, put the cold-pressed green body into a hot-pressing sintering furnace, sinter at 790°C, and keep it warm for 5 minutes. When cooling, the cooling rate is 30°C / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com