Special cutting machine for floor open joint repair batten

A cutting machine and seam separation technology, applied in the manufacture of thin wood chips, wood processing equipment, manufacturing tools, etc., can solve the problems of narrow width, difficult wood strips, easy to break, etc., and achieve simple structure, convenient operation, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

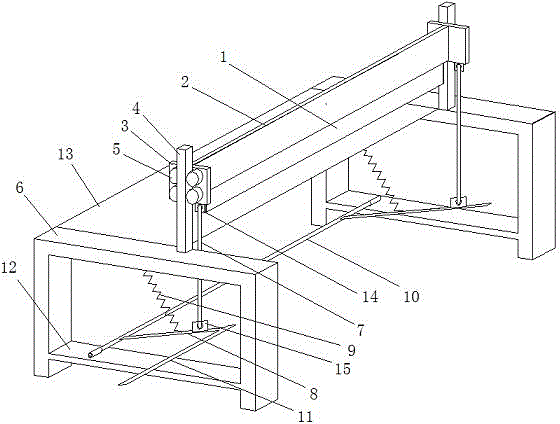

[0012] Such as figure 1 The shown special cutting machine for repairing wooden strips from the floor includes a cutter 1 and a platform 13 with brackets 6 on both sides. There are two positioning plates 3, and the two positioning plates 3 are respectively provided with two rows of guide wheels 5 on one side facing the outside of the platform 13, and guide rods 4 are slidably connected between the two rows of guide wheels 5, and the guide rods 4 are vertically connected respectively. Fixed directly on the brackets 6 on both sides of the platform 13; the cutter 1 is parallel to the end of the platform 13, and the side of the cutter 1 facing the platform 13 coincides with the plane where the end of the platform 13 is located; A driving rod 8 is connected, and one end of the driving rod 8 is fixedly connected to the rotating shaft 10 on the beam 12 of the bracket 6 below the platform 13, the rotating shaft 10 is parallel to the end of the platform 13, and the driving rod 8 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com