Biomass fuel forming machine

A biomass fuel and forming machine technology, applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve problems such as troublesome production operations, achieve convenient operation, prolong service life, and liberate labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

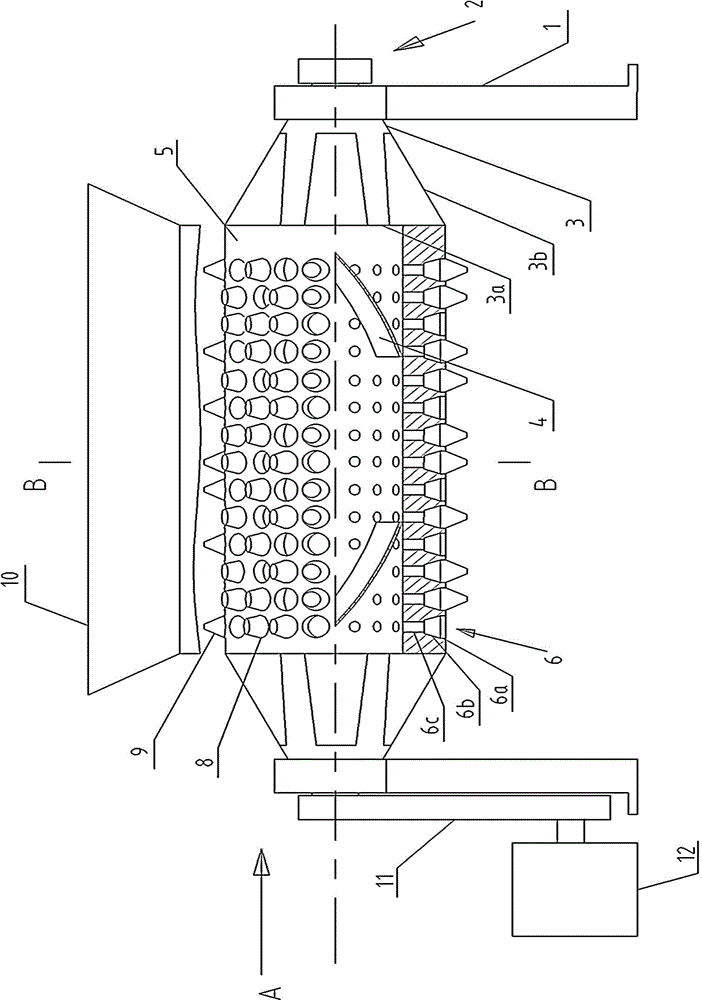

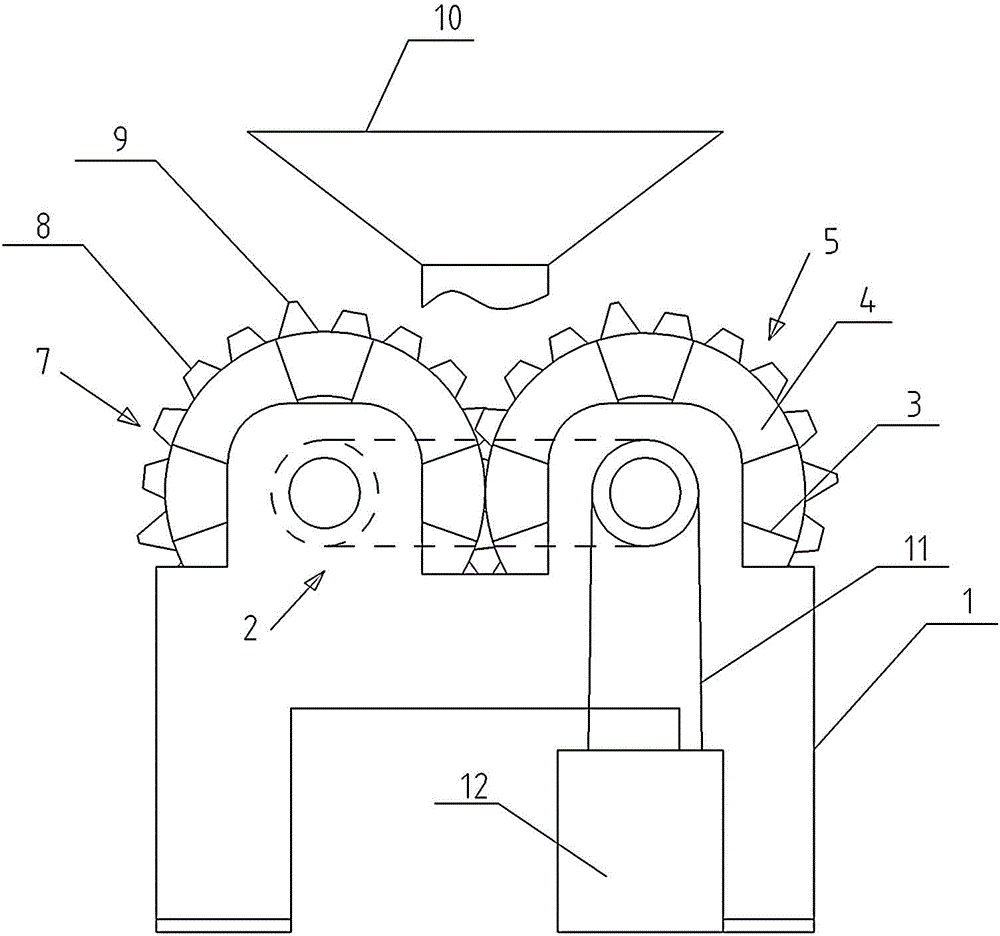

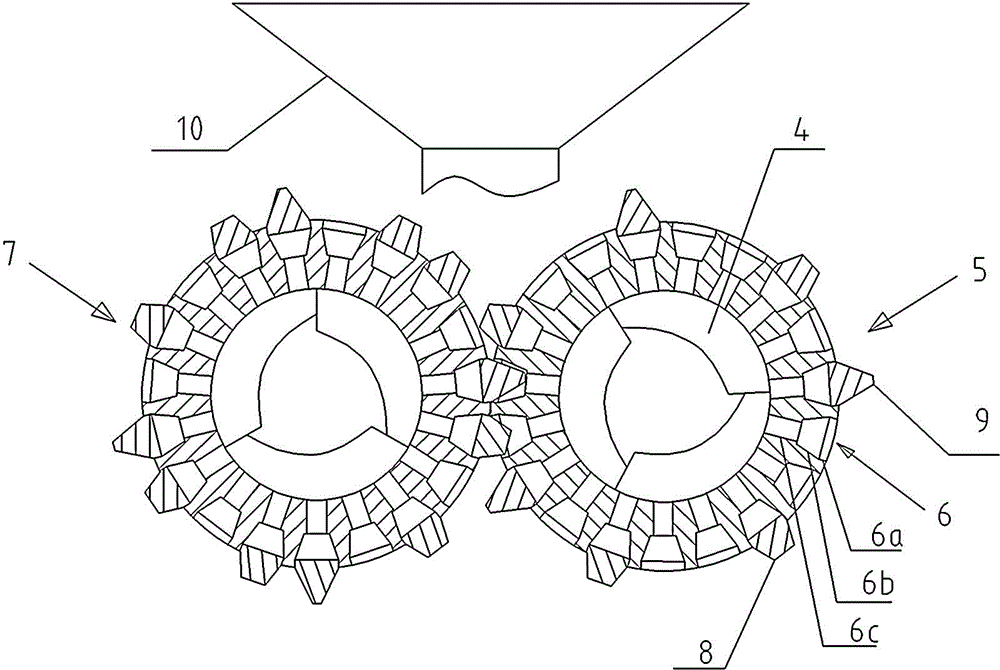

[0018] Such as figure 1 , figure 2 and image 3 As shown, a biomass fuel molding machine provided by the present invention includes a frame 1 on which a driving roller 5 and a driven roller 7 with open ends are arranged, and the corresponding ones of the driving roller 5 and the driven roller 7 are The two sides are attached to each other, and a feed hopper 10 is provided directly above the joint. A group of forming holes 6 are evenly distributed on the driving roller and the driven roller. Each forming hole 6 includes a base hole 6a, and one end of the base hole is connected with a Round table hole 6b, the large-diameter end of the circular table hole is connected with the base hole, and the small-diameter end is connected with a cylindrical hole 6c, and one end of the cylindrical hole is connected with the driving roller 5 and the driven roller 7 in the cylinder. A group of first bosses 8 and second bosses 9 are distributed interspersedly, wherein the first bosses 8 and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com