Tire crane cart walking mechanism tire assembling method

A technology of tire assembly and running mechanism, which is applied in tire installation, tire parts, vehicle parts, etc. It can solve the problems of excessive weight and inappropriateness, and achieve the effects of improving efficiency, convenient assembly, and ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

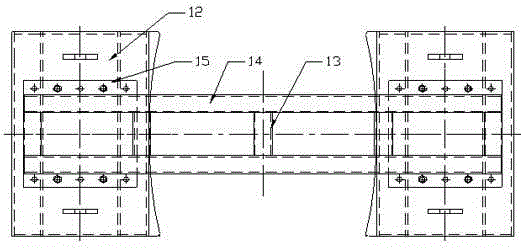

[0025] image 3 The sectional view of the assembled wheel is given, and the various parts can be clearly seen; according to the number, they are: 1-steel ring, 2-tire, 3-valve cover, 4-valve, 5-retaining ring, 6-seat ring, 7-lock ring.

[0026] The invention discloses a tire assembly method for a traveling mechanism of a tire crane cart. The method comprises the following steps:

[0027] The first step is to install the valve: check the airtightness of the valve 4, remove the valve cover 3 on the steel ring 1, install the valve 4 and tighten the nuts, cover the valve cover 3, and put the valve The edge of the mouth cover plate 3 is coated with sealant.

[0028] The second step is to pre-treat the accessories: clean up the water and debris in the tire 2, apply tire removal lubricant on the upper and lower parts of the lip, prepare the accessories of the steel ring 1, and clean the burrs and debris on it .

[0029] The third step is to pre-install the tire: put the tire 2 fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com