Boil-off gas (BOG) liquefying process and device

A process and compressor technology, applied in the field of BOG liquefaction process and device, can solve the problems of combustible gas combustion, environmental pollution, greenhouse effect, etc., and achieve the effects of reasonable heat exchange, simple operation and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

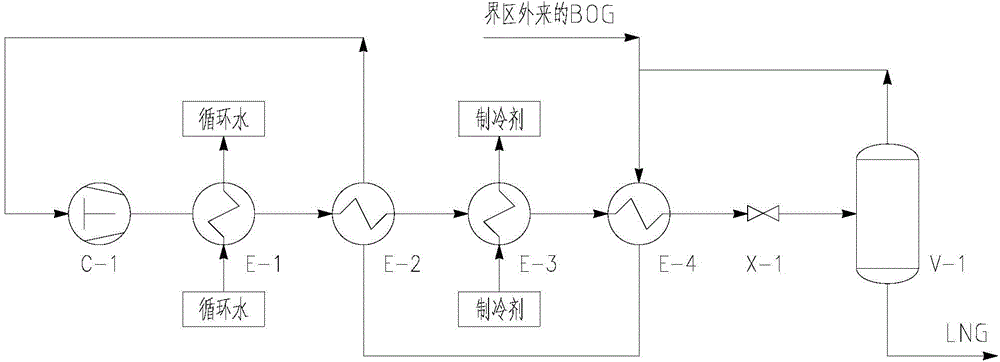

[0025] The invention proposes a BOG liquefaction process, which has a simple liquefaction process, a single refrigerant, and little impact on the original system, and is especially suitable for LNG storage and distribution stations and LNG filling stations.

[0026] Refer to attached figure 1 , the process of the present invention is realized through the following technical solutions: the low-temperature BOG from the LNG storage tank or the LNG loading and unloading system first enters the BOG low-temperature heat exchanger E-4 to recover cold energy, and the cold energy is increased by the BOG compressor C-1 After pressing, the high-pressure BOG is heat-exchanged and reheated to -20~-50°C (for example, -40°C), and optionally enters the BOG normal temperature heat exchanger E-2 for reheating to 15~25°C (for example, 20°C); The heated BOG is pressurized to 10-25MPaA (such as 20MPaA) by BOG compressor C-1, and then cooled to about 40-45°C in compressor aftercooler E-1, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com