Patents

Literature

66results about How to "No leakage issues" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

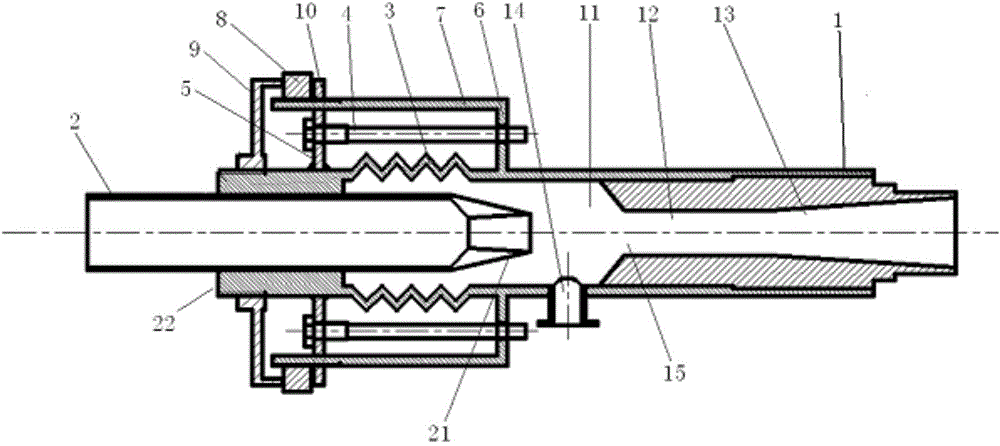

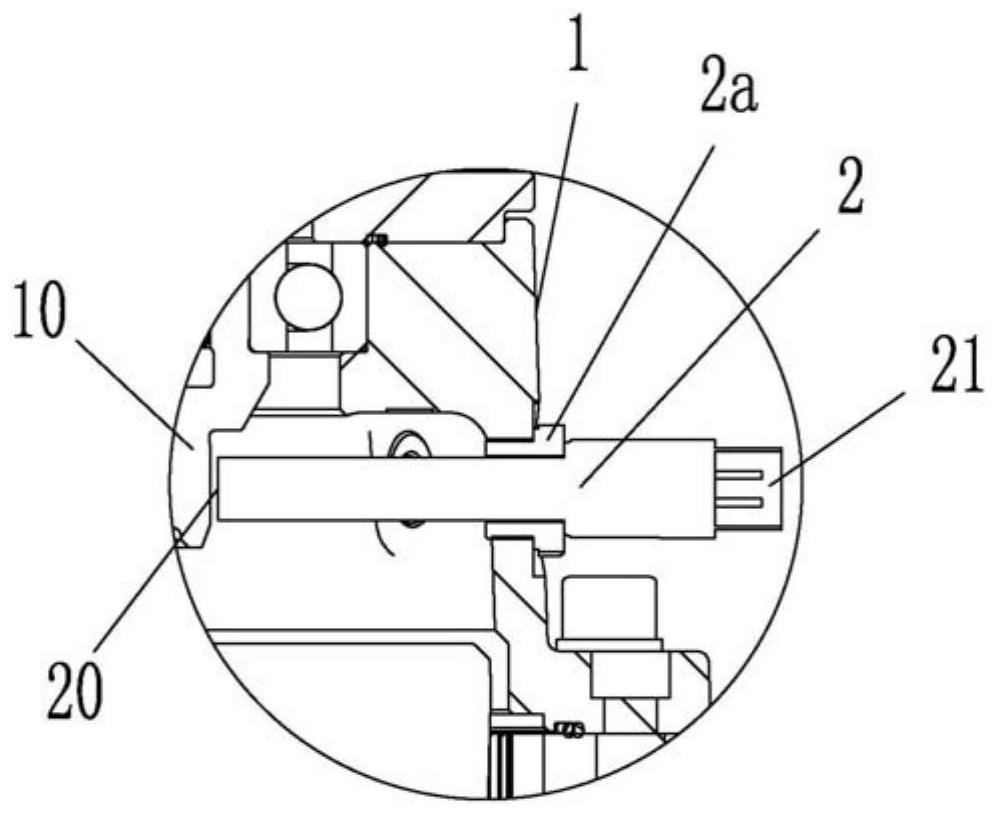

Nozzle-adjustable steam ejector

ActiveCN104675760AImprove performanceSave power steamJet pumpsMachines/enginesInjectorMixing chamber

The invention discloses a nozzle-adjustable steam ejector. The nozzle-adjustable steam ejector comprises an ejector housing with a suction chamber, a mixing chamber and a diffusing chamber inside, and a spray pipe which is partially inserted into the suction chamber, wherein the spray pipe is provided with a nozzle which faces to the mixing chamber. The nozzle-adjustable steam ejector further comprises a retractable pipe which is hermetically connected with the ejector housing and the spray pipe, and an adjusting device which is used for adjusting the distance between the nozzle and the mixing chamber; a guide mechanism is arranged between the spray pipe and the ejector housing. The nozzle-adjustable steam ejector disclosed by the invention has the advantages that of simple structure, low manufacturing cost and simplicity and convenience in installation and disassembling. Not only can the distance between the nozzle and the inlet of the mixing chamber be adjusted, can the performance of the steam ejector be improved and can the ejector be kept to have the optimum working performance within a wider operating range, but also the sealing performance is not influenced during adjustment of the distance between the nozzle and the suction chamber since the spray pipe is hermetically connected with the nozzle with the ejector housing by adopting the retractable pipe, and the problem of leakage caused by a reason that the sealing performance is poor or becomes deteriorated does not exist.

Owner:ZHEJIANG UNIV

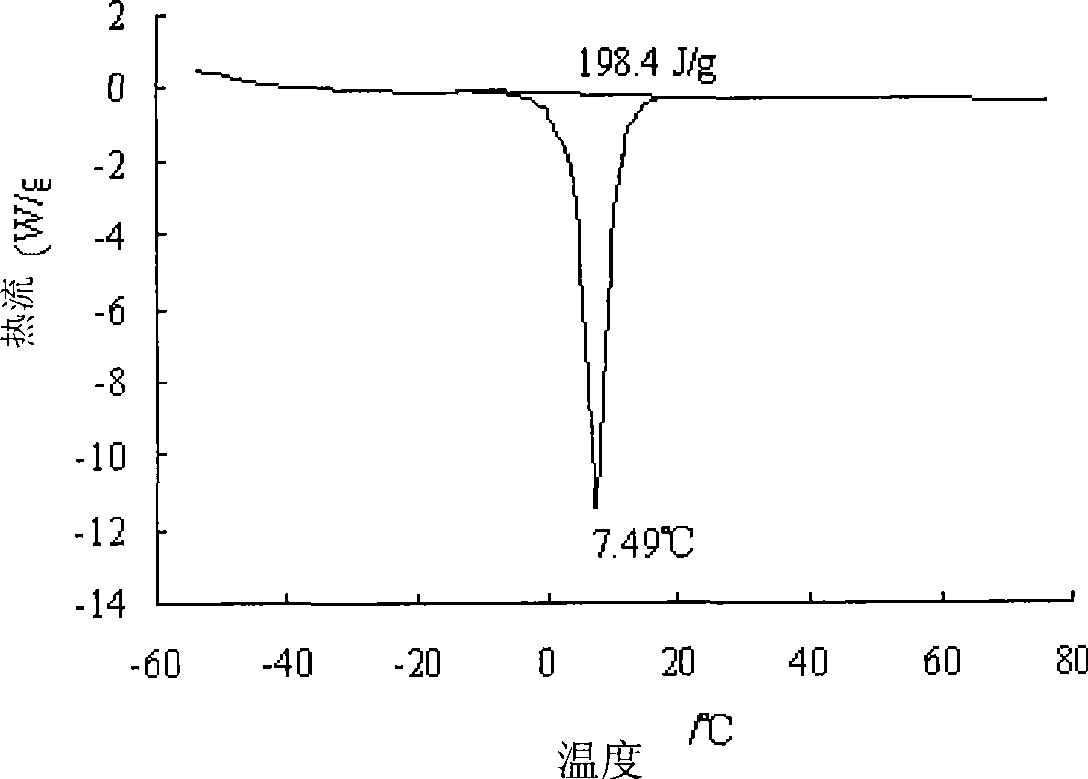

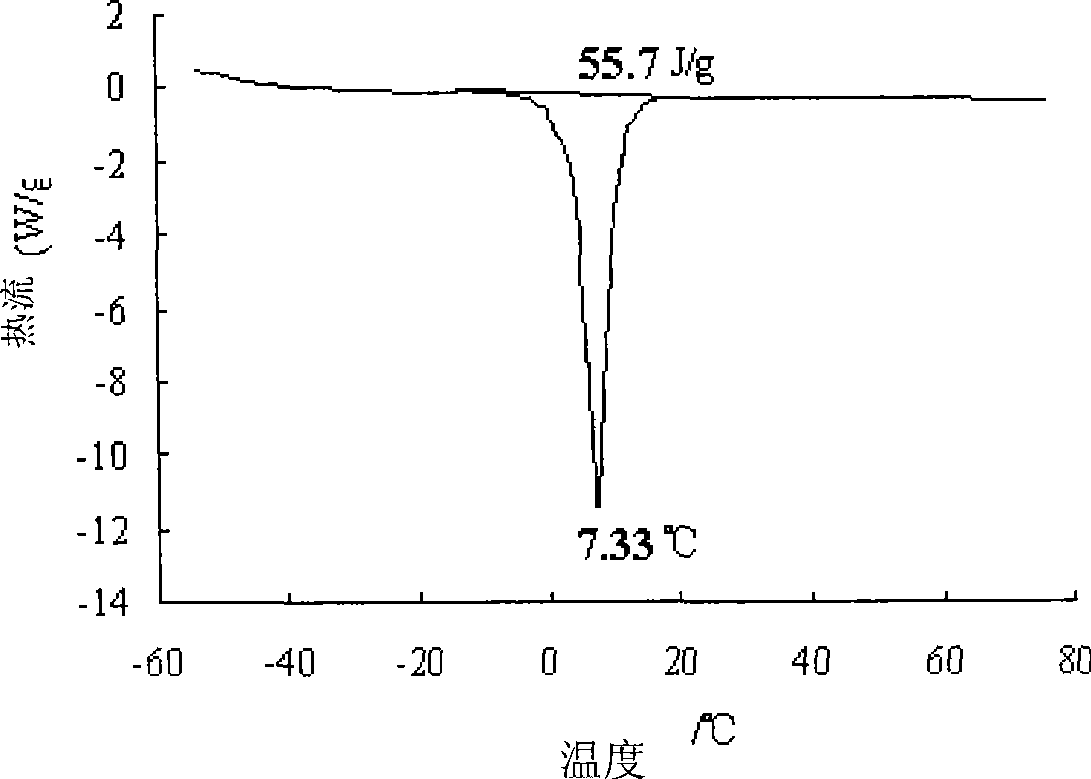

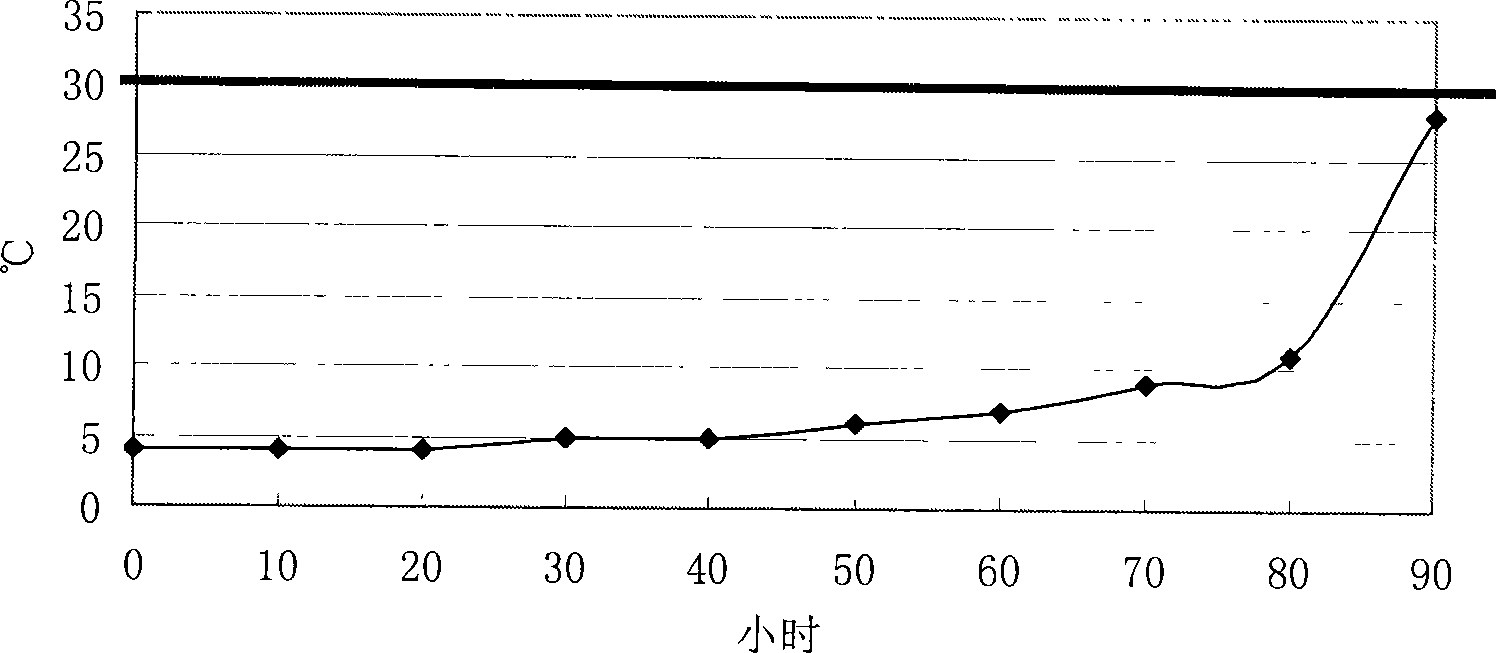

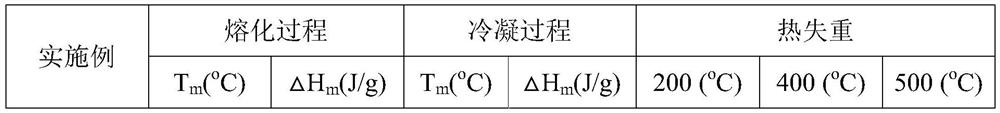

Fixed shape phase-change material based on tetradecane and method for producing the same

ActiveCN101423749AKeep shapeMaintain strengthHeat-exchange elementsPolymer scienceWorking temperature

The invention discloses a figuration phase change material based on tetradecane. The figuration phase change material is formed by mixing and processing the tetradecane with the mass percentage between 30 and 80 percent and the balance being a polymer framework material, wherein the polymer framework material is one or a combination of polyethylene (PE), styrene-butadiene-styrene copolymer (SBS) or styrene-isoprene-styrene copolymer (SIS). The invention has the tetradecane absorbed and / or wrapped in the specific polymer material as a framework. Because the polymer material as the framework can not be deformed in the working temperature range (20 below zero to 40 DEG C for example) of the tetradecane, the shape of the material can be kept, and the problems about collapse or flowing and leakage can not occur. Therefore, the obtained figuration phase change material can be widely applied to the low-temperature preservation and transportation of medicines, foods and the like.

Owner:FIELD OPERATION BLOOD TRANSFUSION INST OF PLA SCI ACAD OF MILITARY

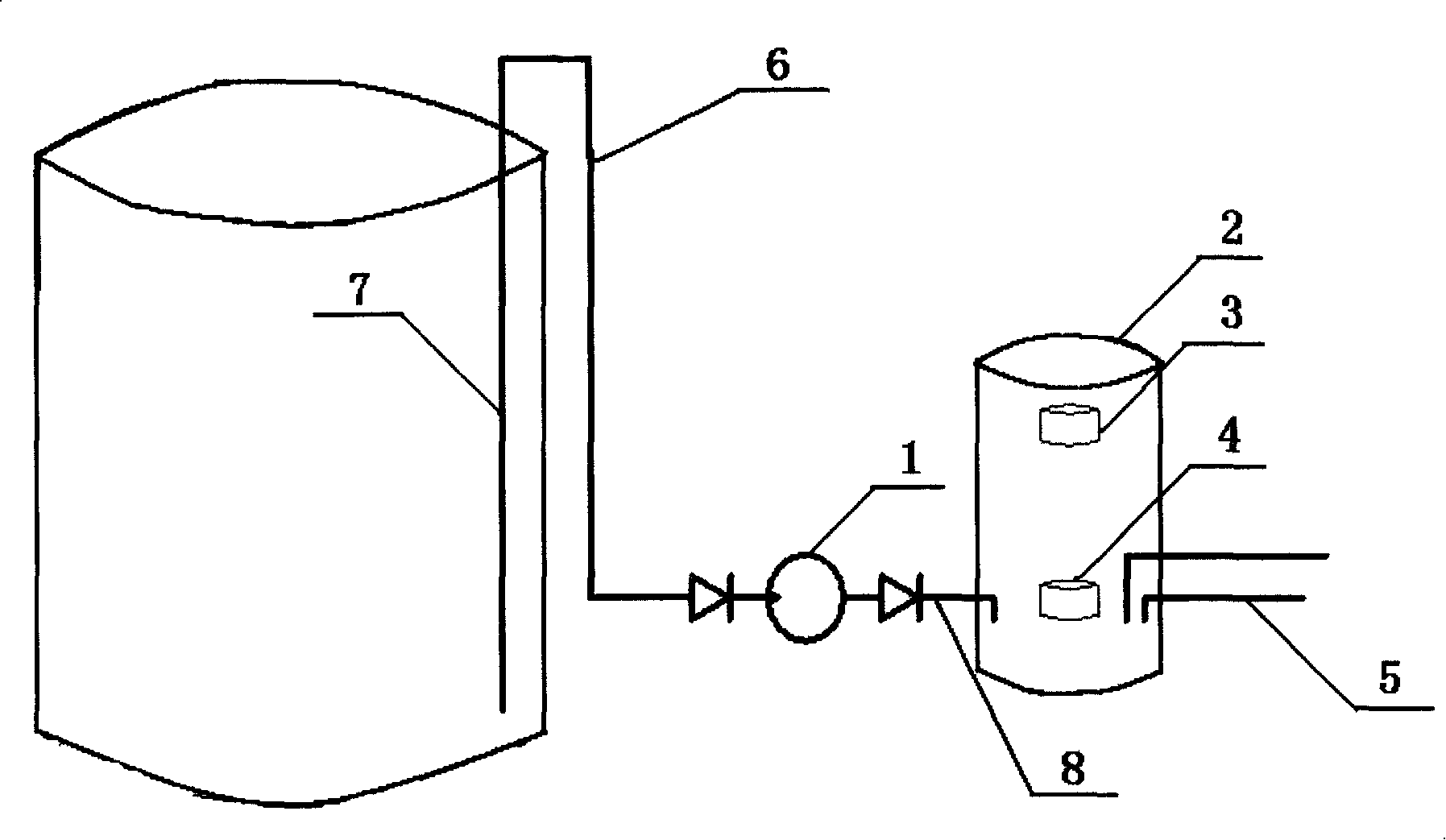

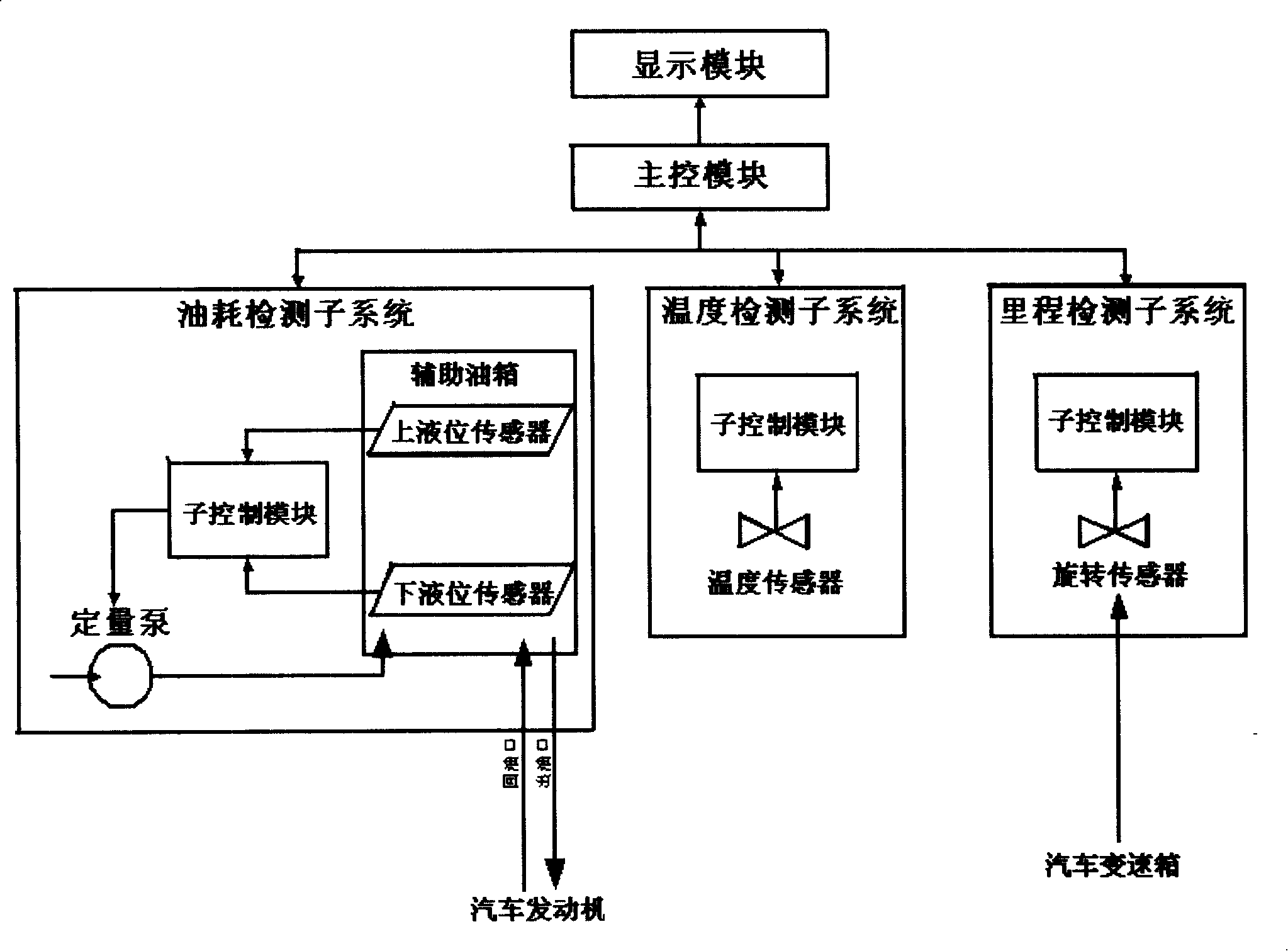

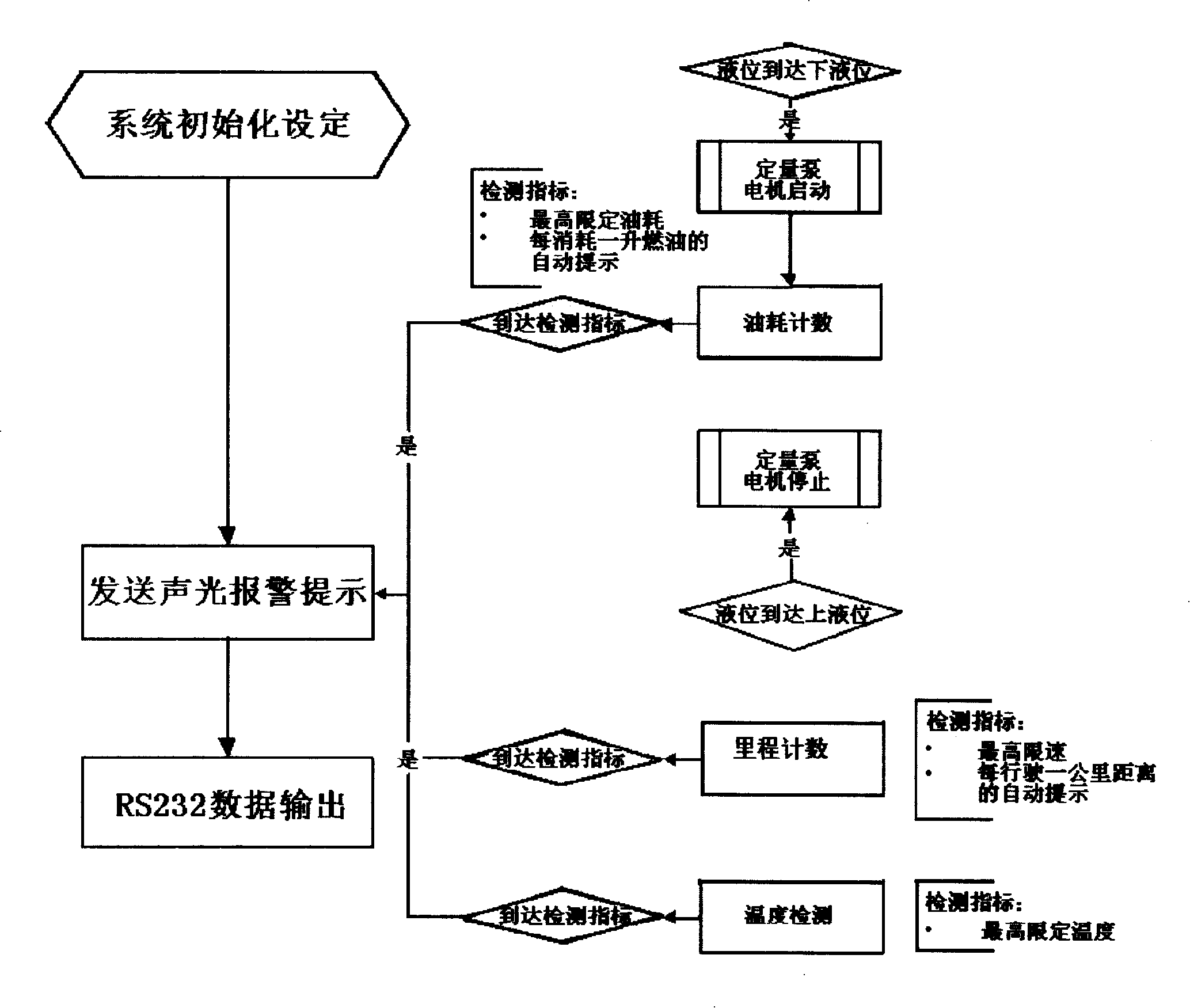

System and method for detecting practical oil consumption and mileage of motor vehicle

InactiveCN101196418ASolve the problem of fuel consumptionSimple structureVehicle testingThermometer detailsThird partyAutomatic control

The invention provides a vehicle practical gasoline consumption and mileage detecting system and the detecting method, which is used for detecting automatically and analyzing the gasoline consumption and driving mileage and temperature. The detecting system comprises a main control module, used for collecting and sorting data, data communicating and finishing automatic control logic; a gasoline consumption detecting sub-system, using the electromechanical automatic control component to conduct practical gasoline detecting; a driving mileage detecting sub-system, calculating out the practical driving mileage of vehicle and current speed through counting the turning circle of main axle of gear-box; a temperature detecting sub-system installed at the position assigned by user; a display module, used for counting the data including driving mileage, gasoline consumption and the tested temperature during the driving process of vehicle, and display the data to the driver through LED. The system has simple structure and high detecting precision, which can finish detecting work automatically and quickly. The whole process doesn't need the third party to interfere in, thus the applicability is high.

Owner:广东新蓝德信息产业有限公司

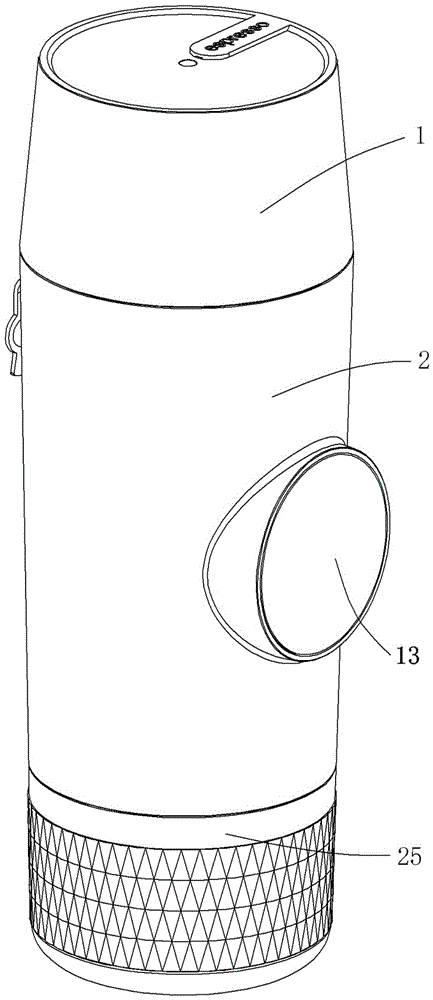

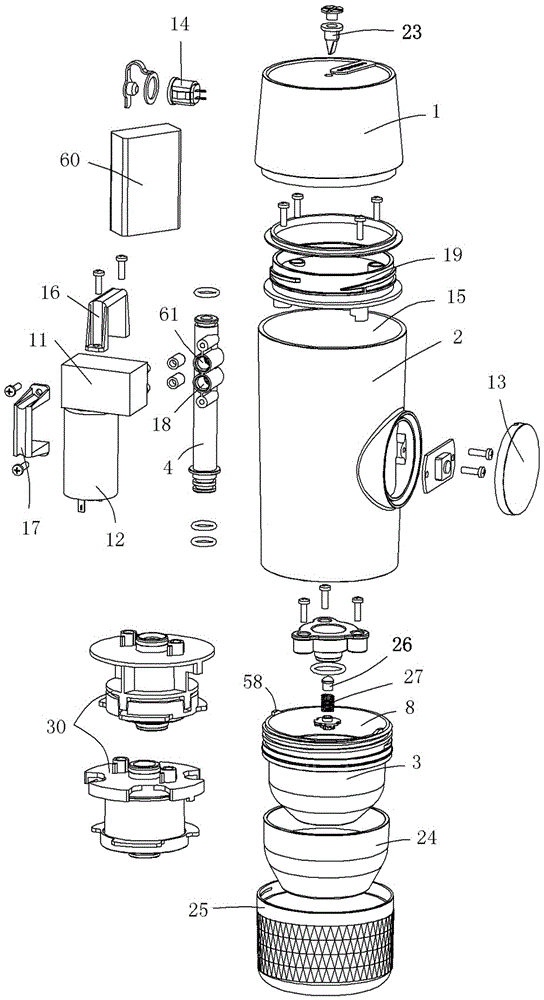

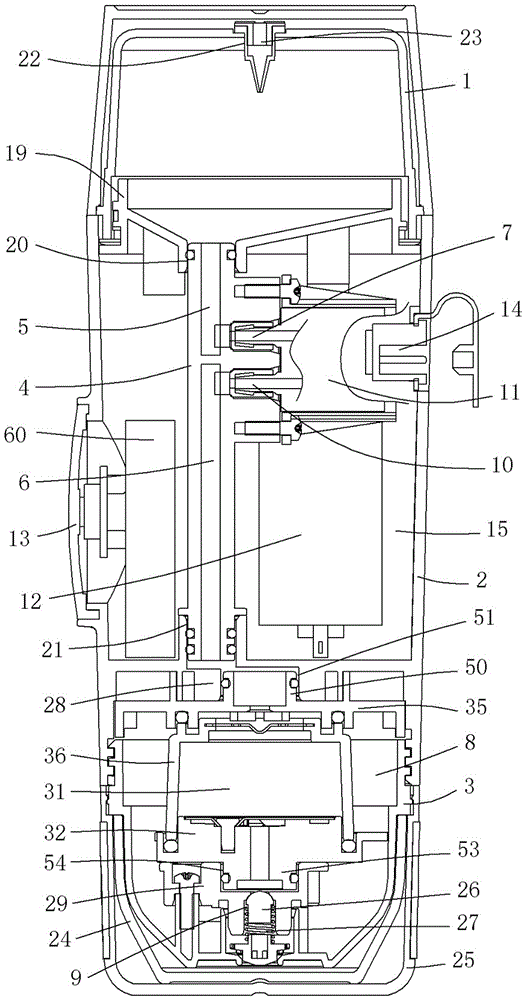

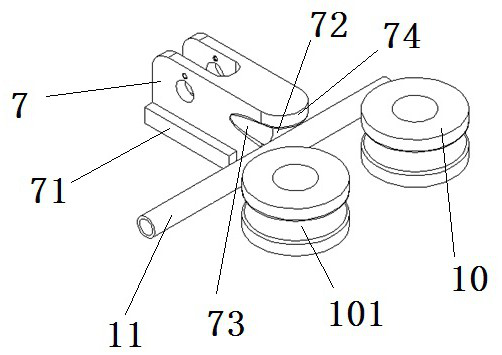

Portable coffee maker

ActiveCN106724821AReduced sealing requirementsEasy to operateBeverage vesselsInlet channelPore water pressure

A portable coffee maker comprises a cup body, a water pressure seat body and a coffee making seat body, wherein a water pump component, a water inlet channel and a water outlet channel are arranged in the water pressure seat body, the water inlet channel and the water outlet channel are not communicated with each other, the water inlet channel is communicated with the cup body and a water inlet of the water pump component, a containing cavity communicated with the water outlet channel and used for brewing coffee and a coffee outlet channel communicated with the containing cavity are formed in the coffee making seat body, and the water outlet channel is communicated with the containing cavity and a water outlet of the water pump component. The portable coffee maker has the advantages that hot water in the cup body is directly pumped into the containing cavity by the water pump component to brew coffee, the operation is very simple, water pressure can be up to 15 bar after the hot water passes through the water pump component, the water pressure requirement of a user is completely met, made coffee is rich, the brewing quality is good, and meanwhile the portable coffee maker is simple and compact in structure, small in size and convenient to carry. In addition, the cup body does not need to bear pressure, the sealing requirement is not high, and no leakage problem exists.

Owner:CIXI OWNER ELECTRICAL APPLIANCE

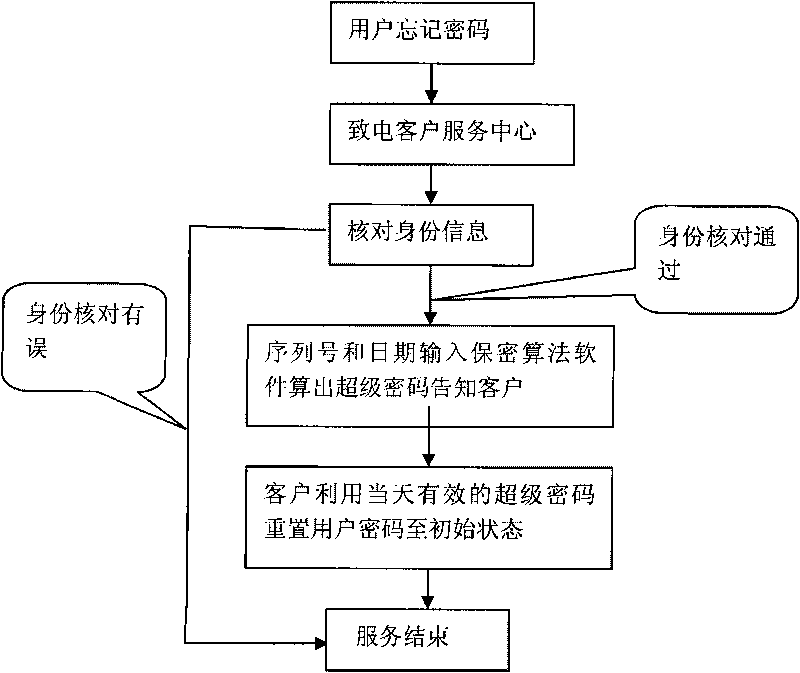

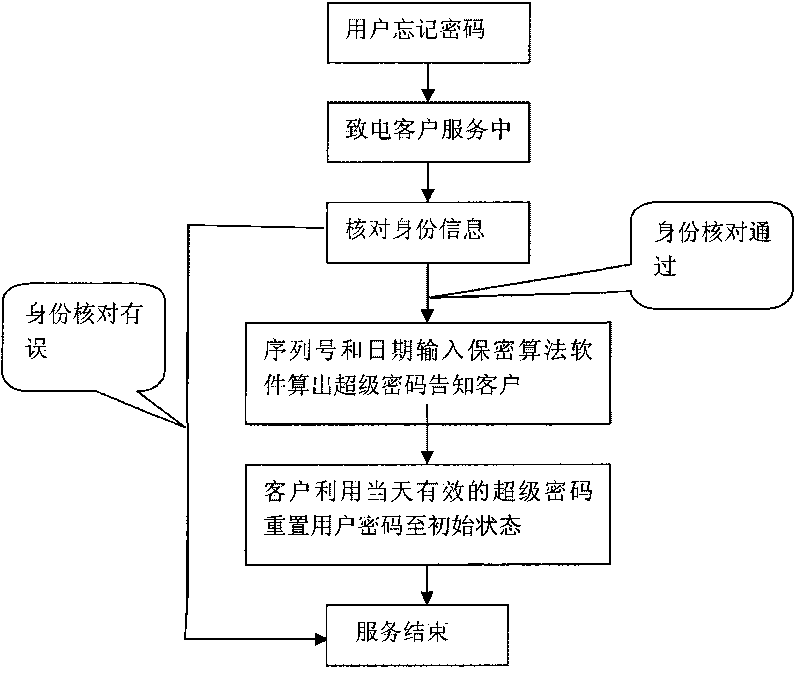

Dynamic password control method

InactiveCN101742060ANo leakage issuesTelevision system detailsAnalogue secracy/subscription systemsUser inputPassword

The invention discloses a dynamic password control method which comprises the following steps: a. an encryption algorithm F is set in equipment / software, and the encryption algorithm takes the characteristic value and date of the equipment as variables; b. when losing the password, a client puts forward an inquiry request to a service provider; c. the service provider firstly check the identity of the client, then extract the characteristic value and the date of the current day of the client, starts the encryption algorithm to produce a superior password P1 and returns the superior password P1 to the client, wherein the encryption algorithm is as the same as the encryption algorithm F set in the equipment / software; d. the client inputs the superior password P1 into the equipment, the equipment starts the set-in encryption algorithm F after receiving the input of the client, and a superior password P2 can be calculated by taking characteristic value and the date of the current day of the equipment as variables; and e. the equipment compares superior passwords P1 and P2, when P1 and P2 are identical, the equipment verifies the superior password input by the client to be valid, thus the client password is reset to the initial password. The dynamic password control method provided in the invention effectively solves the leakage of the superior password with simple operation.

Owner:KONKA GROUP

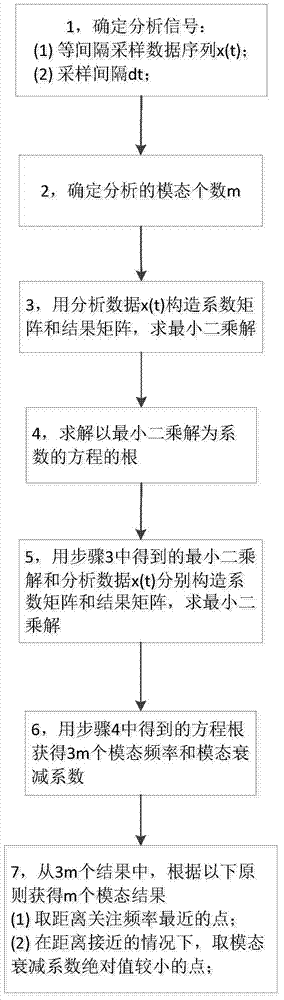

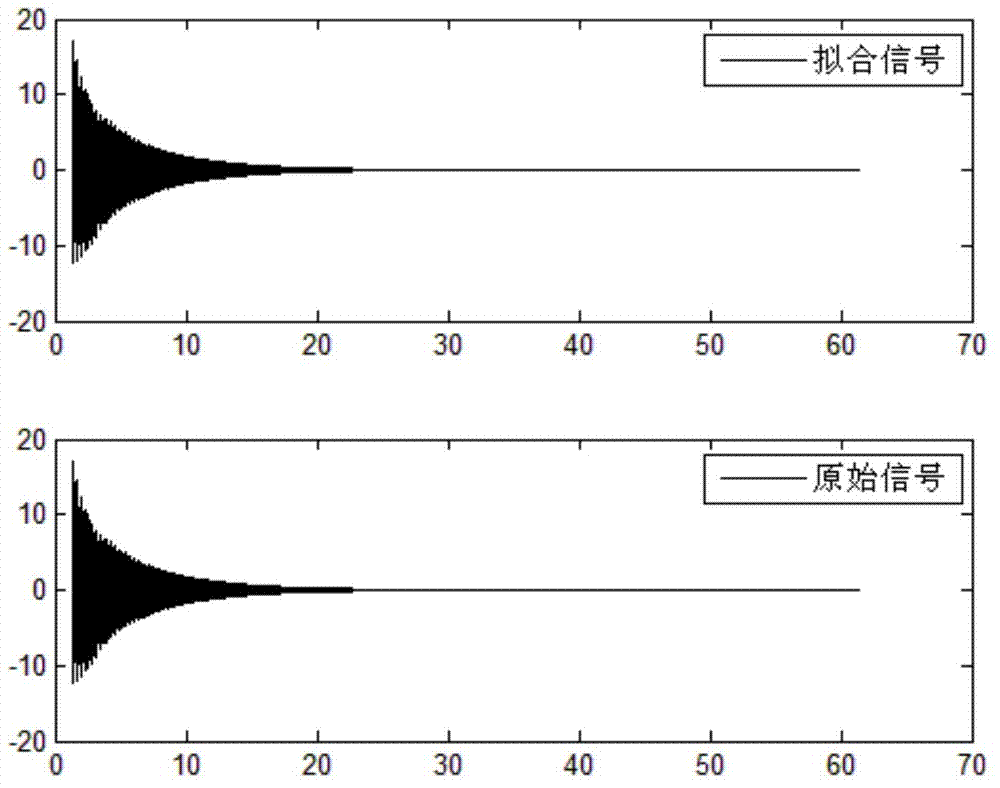

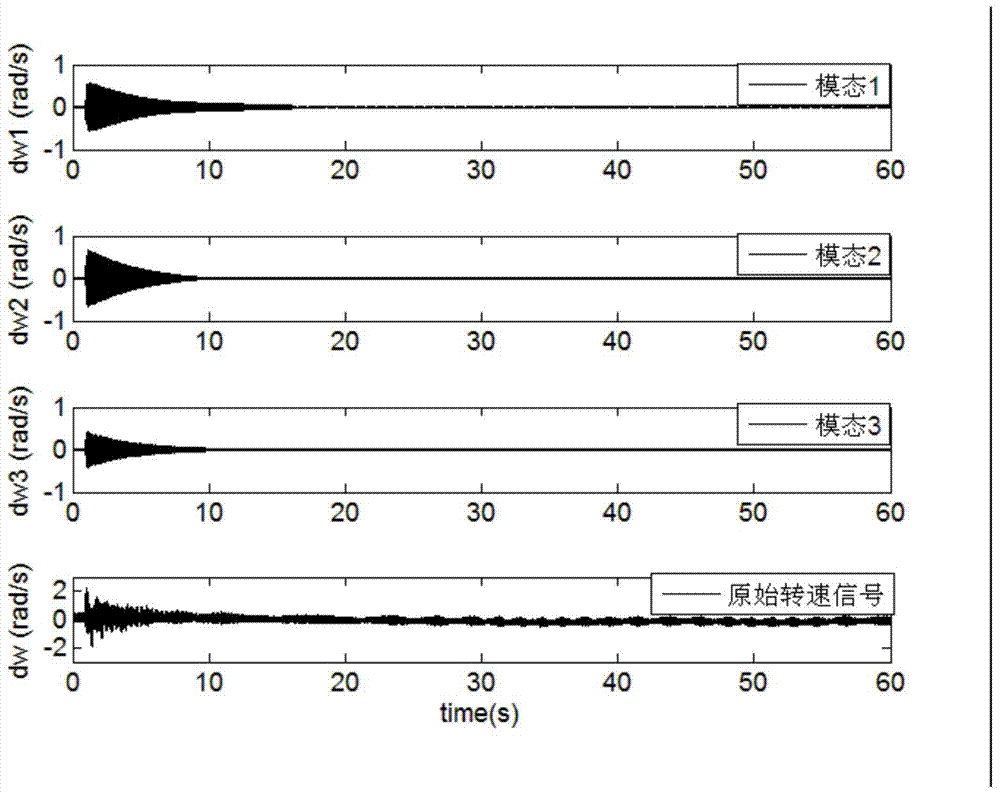

Calculation method of sub-synchronous oscillation mode attenuation coefficients based on Prony algorithm

InactiveCN104852392AImprove noise immunityAccurate and fast calculationPower oscillations reduction/preventionSpecial data processing applicationsAttenuation coefficientUltrasound attenuation

The invention relates to a calculation method of the sub-synchronous oscillation mode attenuation coefficients based on Prony algorithm, and mainly aims at solving the problem in extracting key modal parameters as modal frequency and attenuation coefficients from sub-synchronous signals. The calculation method is based on the Prony algorithm, takes shafting rotating speed signal of high sensitivity as input signals, employs least square fit, greatly eliminates influence of noise signals, requires no filtering, reserves all data information, is capable of extracting multiple modal information, and thus, extracts attenuation coefficients of different modes accurately and rapidly.

Owner:SHENHUA GUOHUA (BEIJING) ELECTRIC POWER RES INST +1

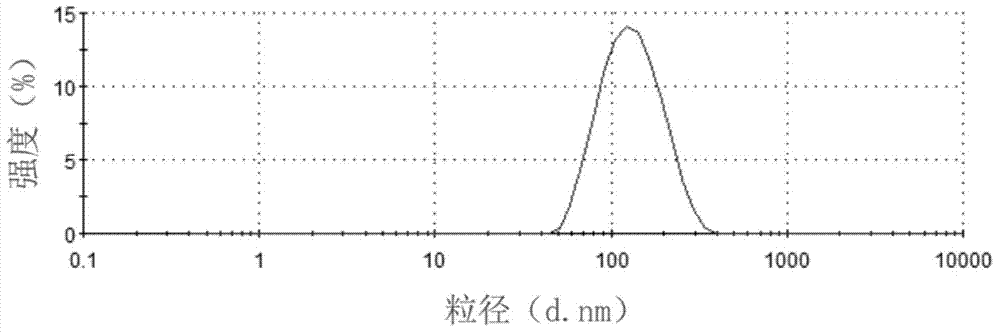

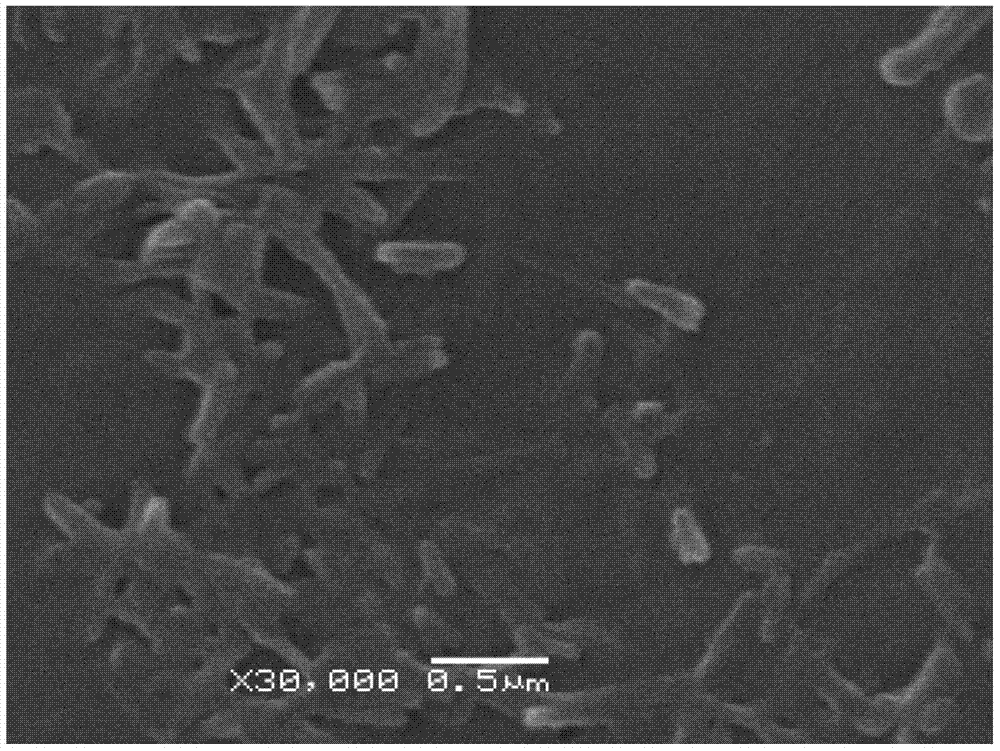

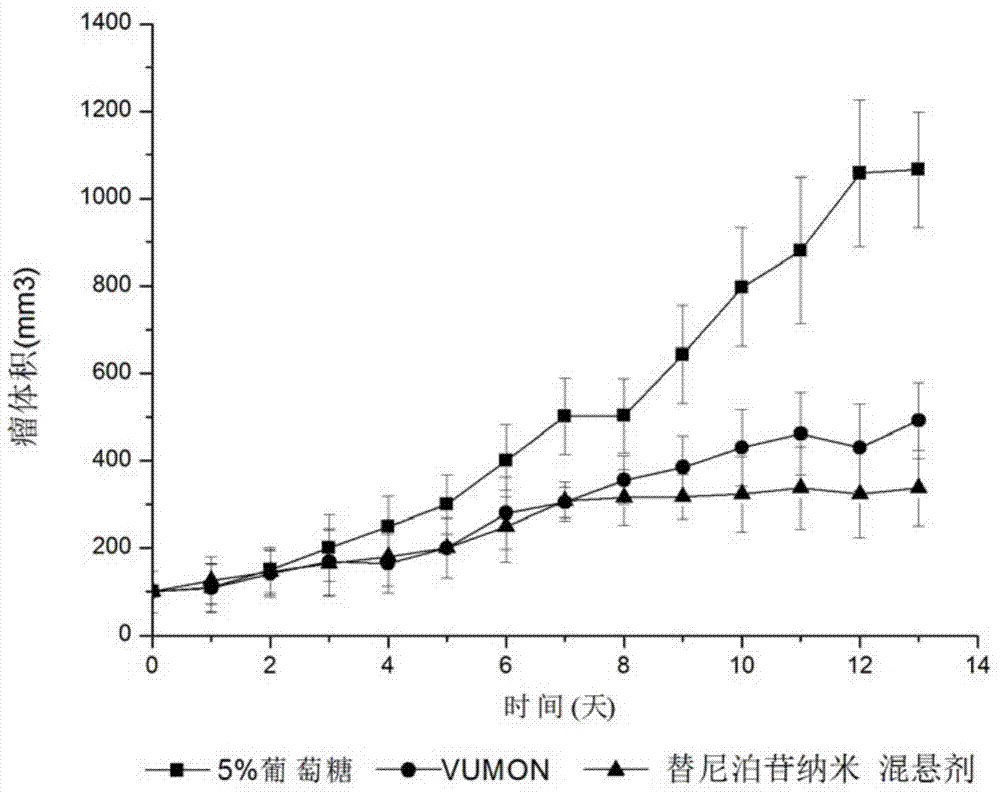

Teniposide nanosuspension and preparation method thereof

InactiveCN104288100AFully exert antitumor activityHigh drug loadingOrganic active ingredientsSolution deliverySide effectClinical efficacy

The invention discloses a teniposide nanosuspension and a preparation method thereof. Each 1ml of the nanosuspension contains 0.1-50mg of teniposide, 0.1-500mg of a stabilizer, 0-500mg of an additive, and the balance of water. Compared with commercially available teniposide injections (VUMON), teniposide intravenous emulsions, teniposide solid lipid nanoparticles and phospholipid complex liposomes, the teniposide nanosuspension has the advantages of high drug load, good stability, no carriers or co-solvents, avoiding of the use of organic solvents, low toxic side effects, reduction of the untoward reactions of patients, good patient compliance; high-efficiency low-toxicity performance of the antitumor activity of teniposide, good clinical curative effect and good application prospect.

Owner:HENAN UNIV OF SCI & TECH

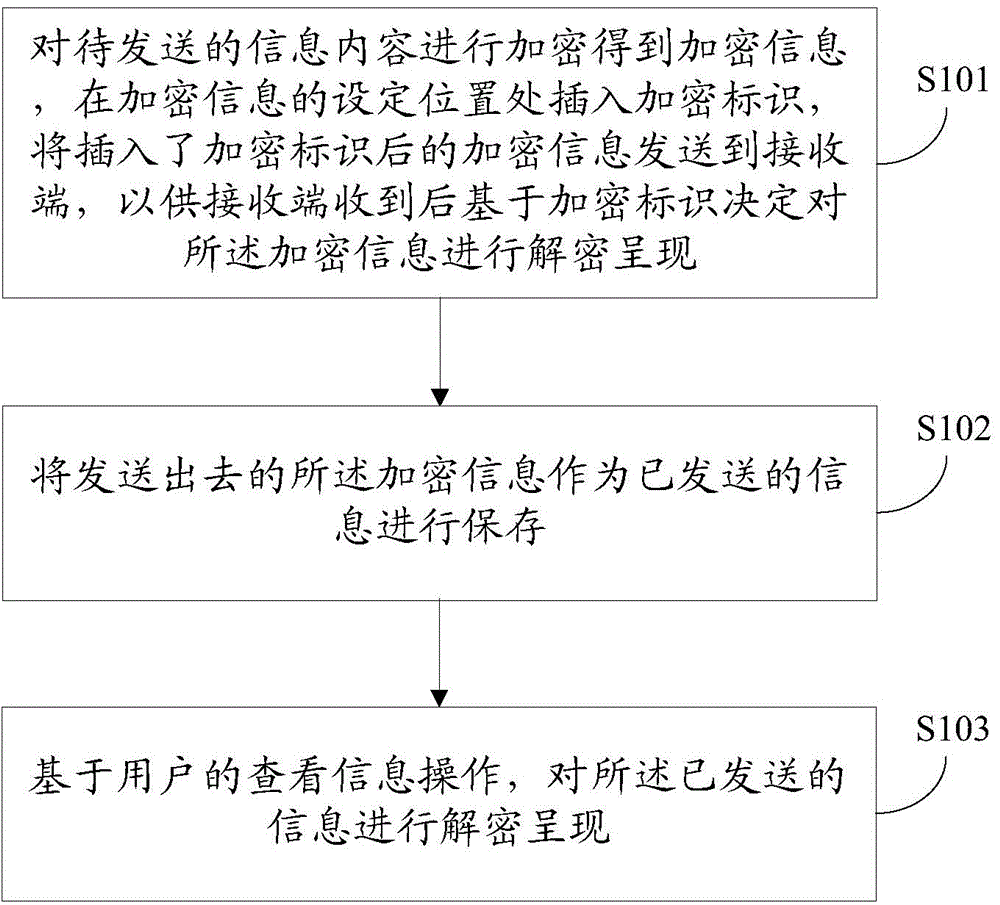

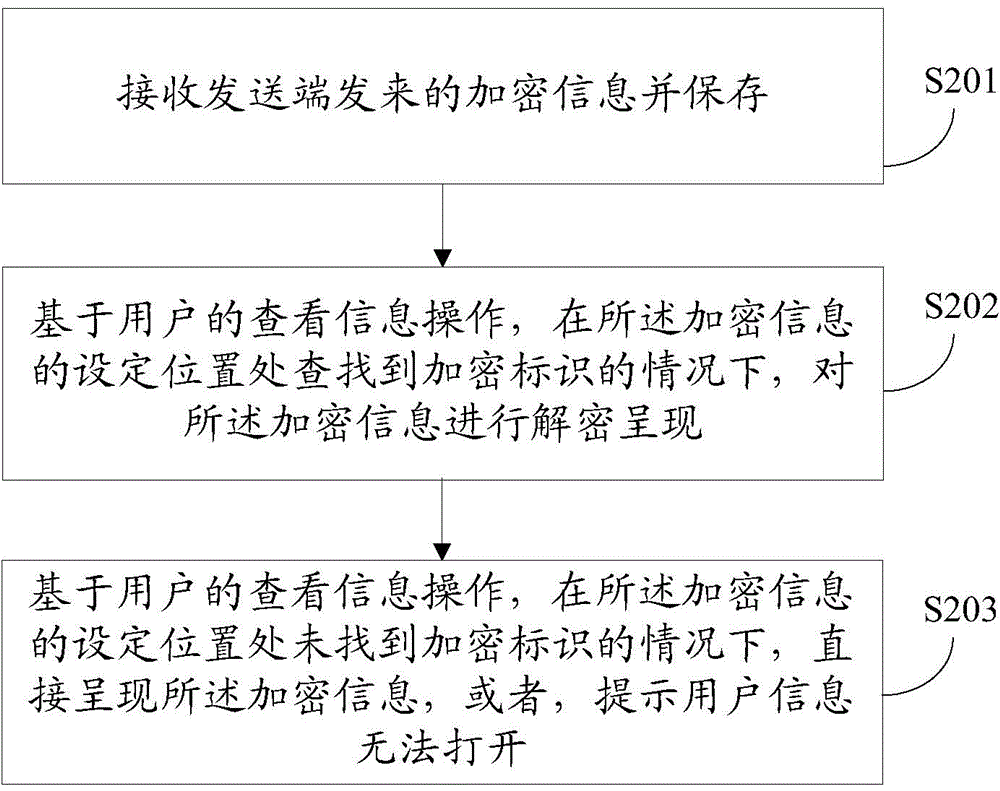

Information transmission method and mobile terminal

InactiveCN105391677AEnsure safetyNo leakage issuesEncryption apparatus with shift registers/memoriesMessaging/mailboxes/announcementsUser needsInformation transmission

The invention proposes an information transmission method and a mobile terminal. During information transmission, the mobile terminal provided by the invention is used for transmitting and receiving a short message, thereby causing no leakage of the short message even if the short message is sent to other common mobile terminals. Because a transmitting end and a receiving end stores and transmits information in an encrypted manner, information decryption display for a user based on an encryption identification can be determined to be carried out only if the user needs to check the detail of the information, thereby guaranteeing the safety of information transmission. Moreover, even if the information data of the user in the mobile terminal is copied to other electronic equipment, such as a computer, the user does not need to worry about the leakage of the contents of data because other equipment does not have a decryption function corresponding to the mobile terminal.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

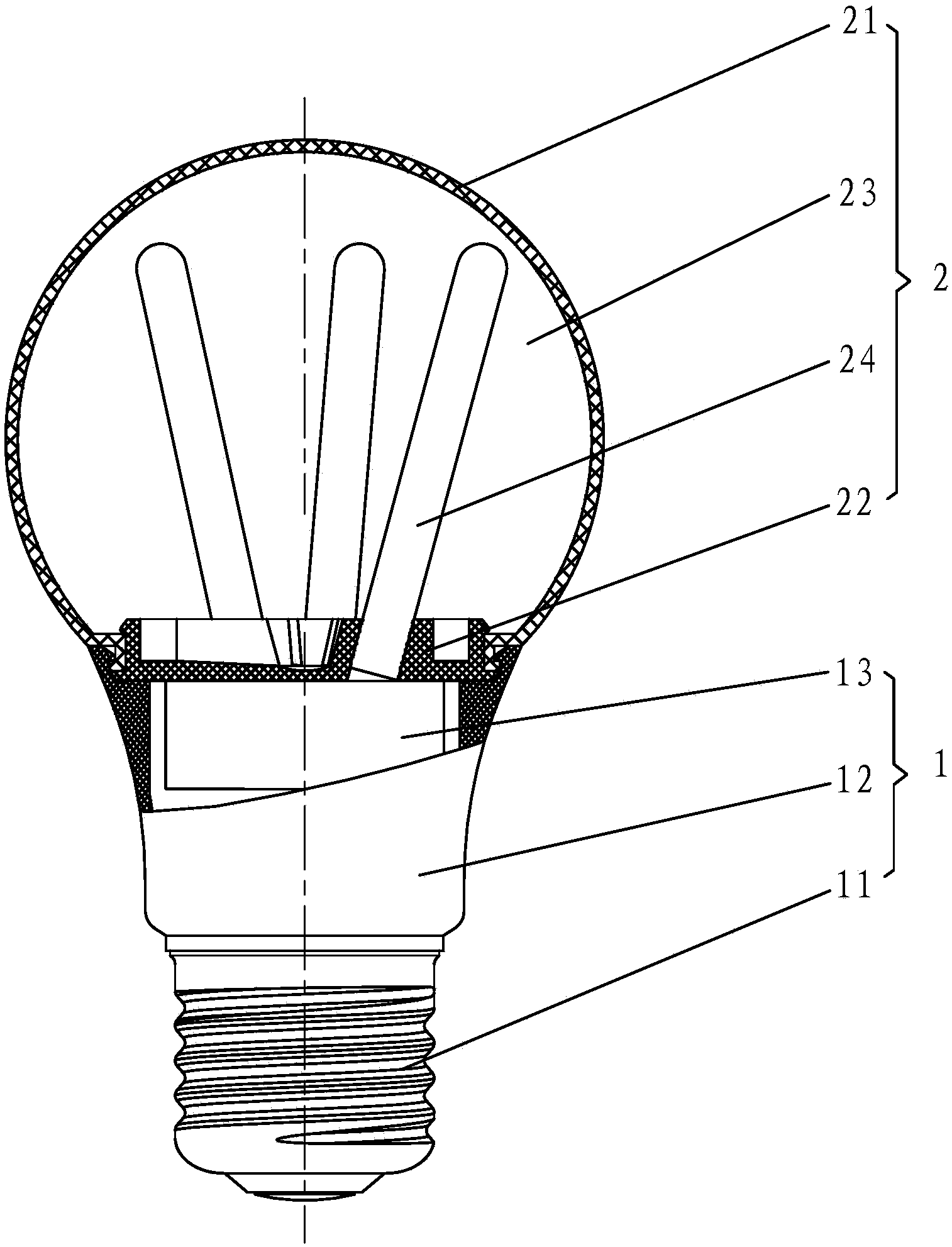

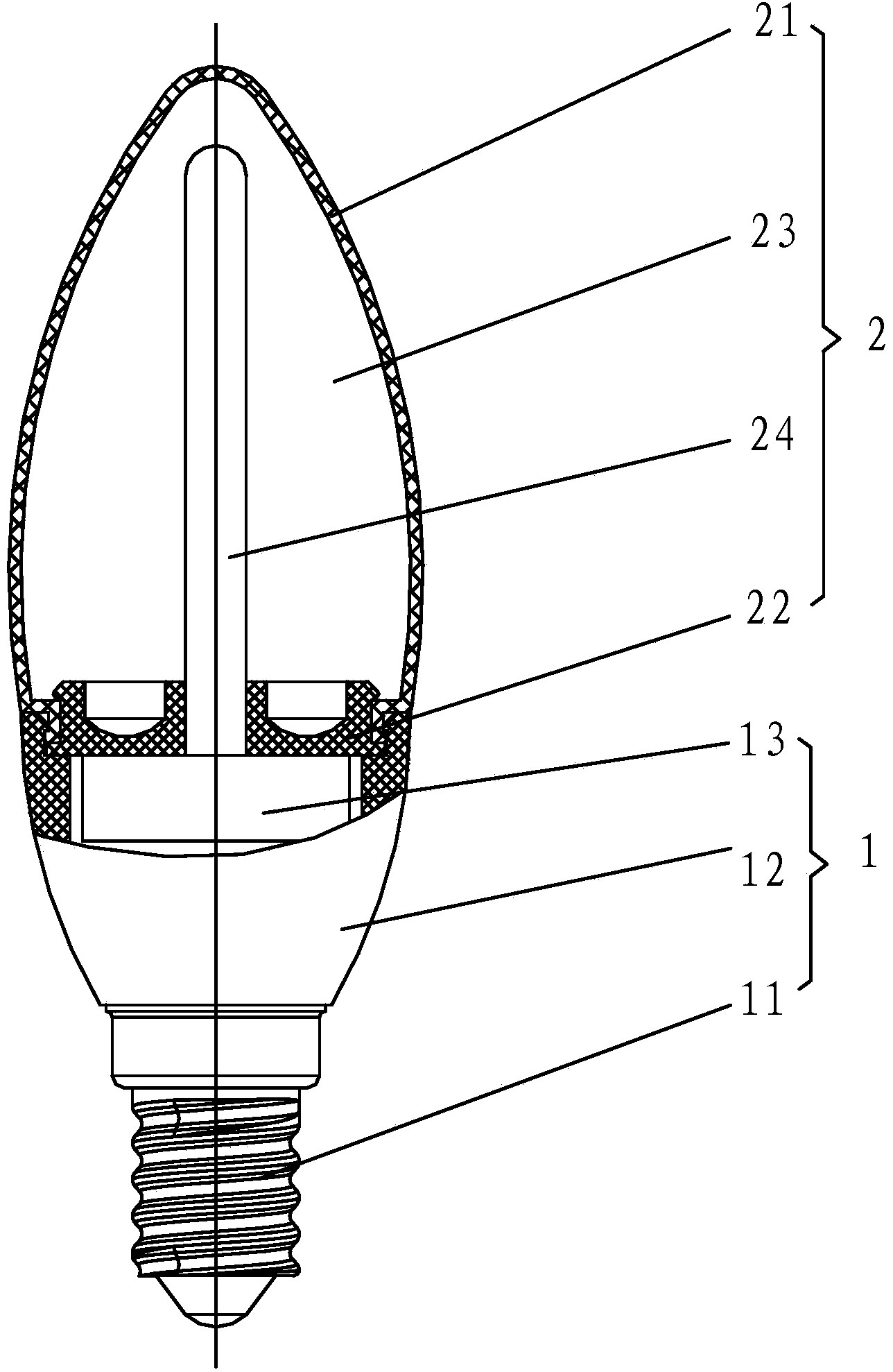

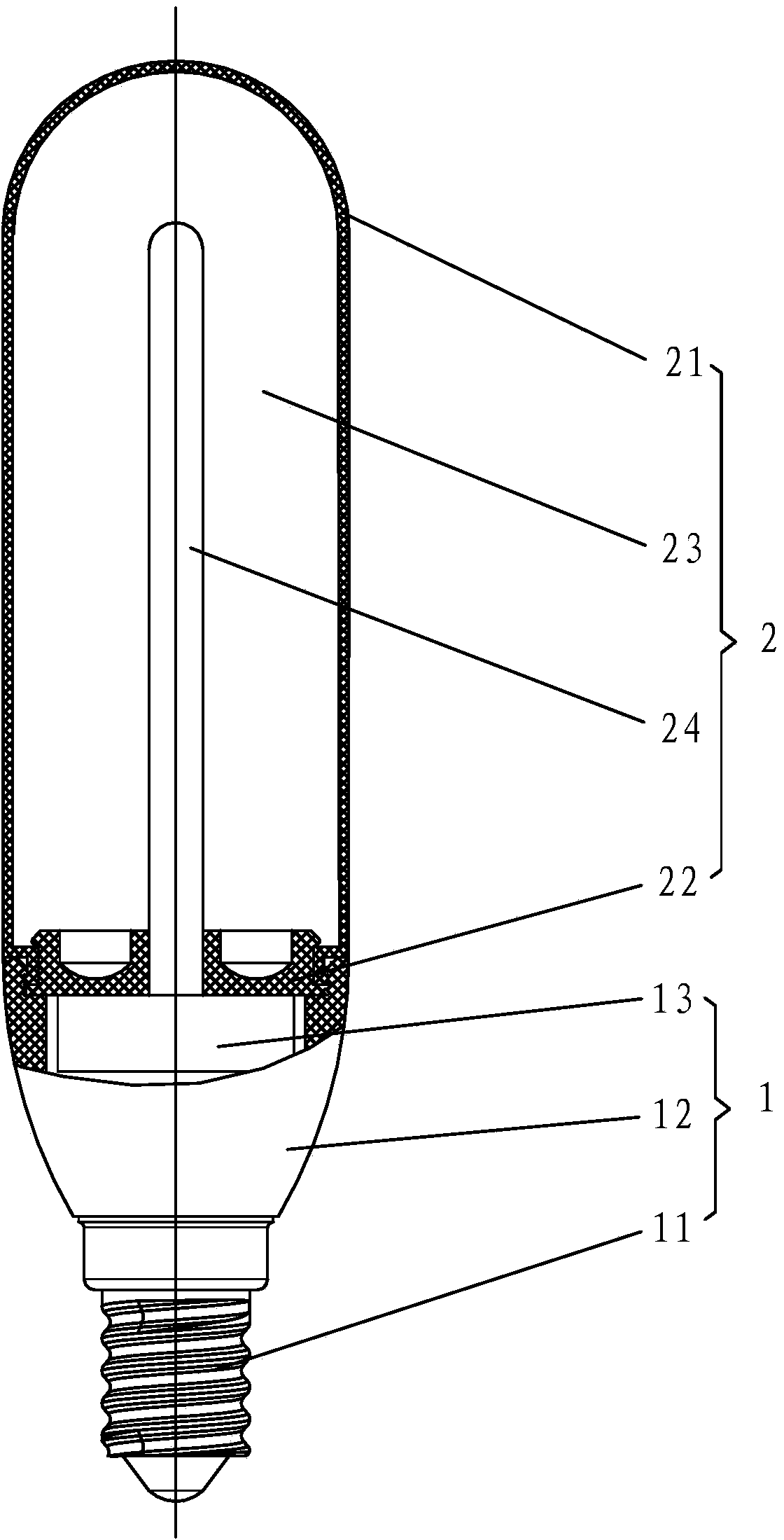

LED (light emitting diode) illumination light source

InactiveCN103867943ALight evenlyRealize omni-directional heat conductionPoint-like light sourceLighting heating/cooling arrangementsHeat conductingLight transmission

The invention belongs to the technical field of an LED (light emitting diode), and particularly relates to an LED illumination light source, which comprises a light transmission lamp shade, an elastic sealing cover, heat conduction light transmission cooling liquid and an LED luminous element, wherein the light transmission lamp shade and the elastic sealing cover are connected in a sealed way for forming a sealed space, the LED luminous element is arranged in the light transmission lamp shade and is fixedly arranged on the elastic sealing cover, and heat conducting light transmission cooling liquid is filled in the sealed space. The invention aims at solving the technical problems to provide the LED illumination light source with the advantages of heat conducting light transmission cooling liquid cooling, all-direction heat conduction and all-direction uniform light outlet.

Owner:FUJIAN YDJ LIGHT

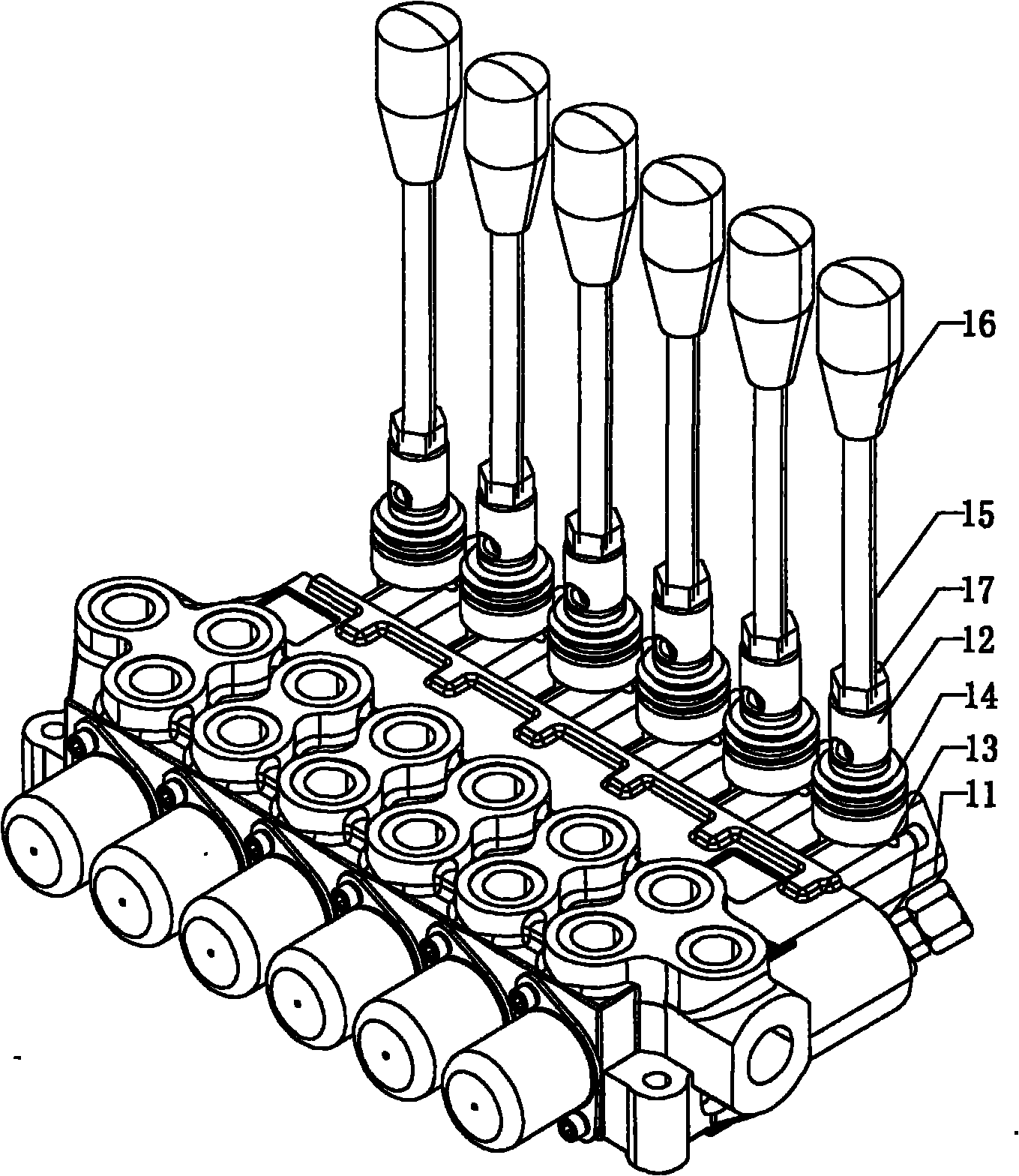

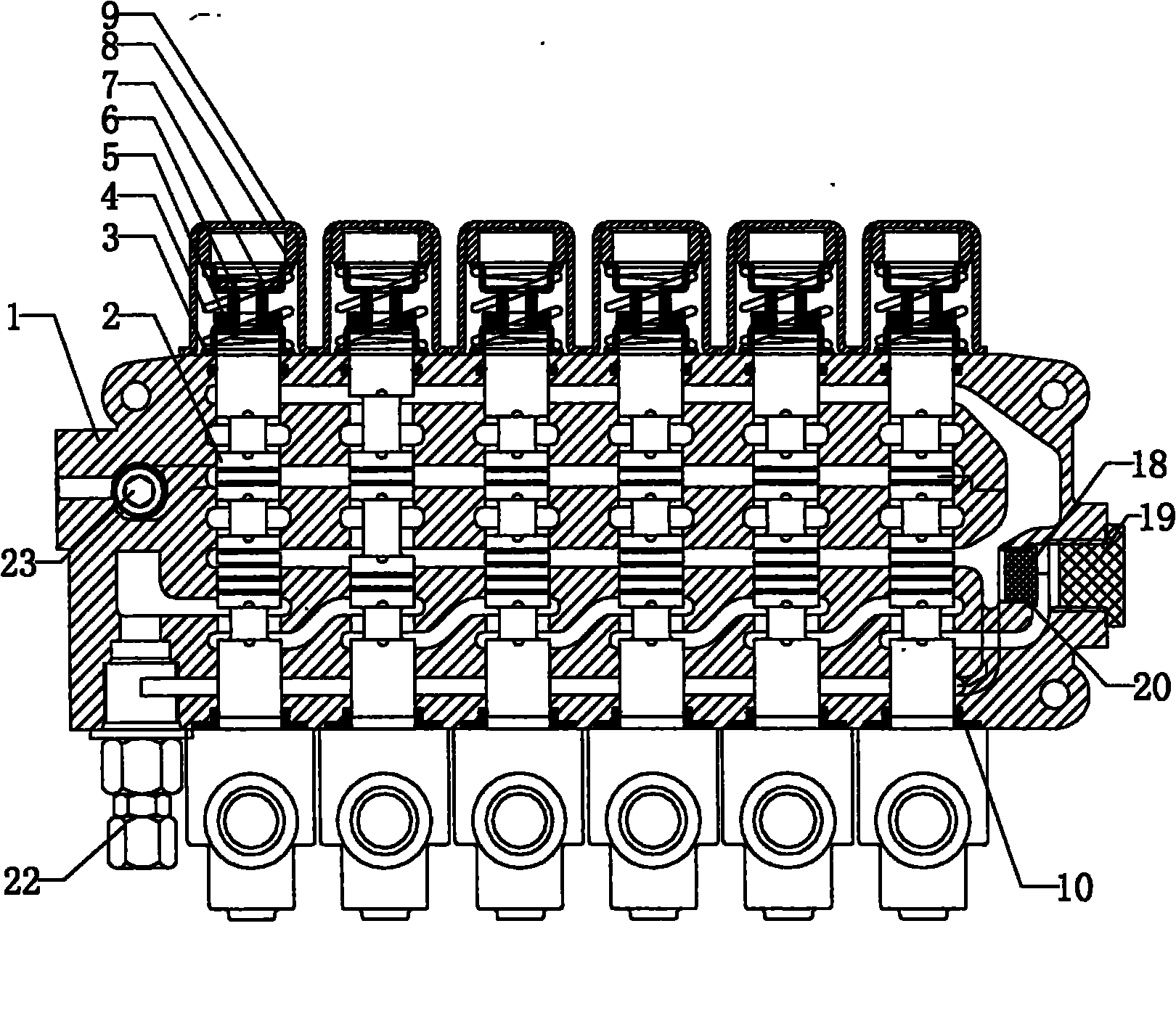

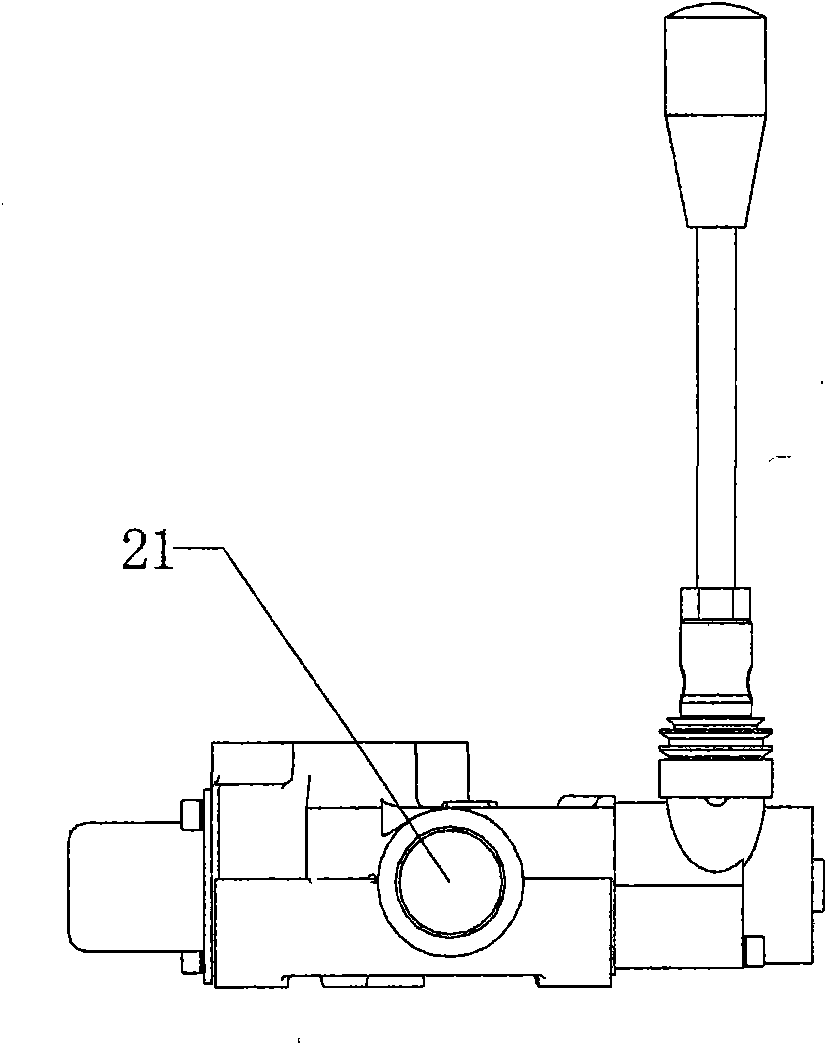

Integral multi-way reversing valve

InactiveCN101846107ANo effect on pressure lossNo impact lossOperating means/releasing devices for valvesServomotor componentsInlet valveEngineering

The invention relates to an integral multi-way reversing valve, which comprises an operating handle, a valve body, an end cover and a front cover, wherein the upper end of an operating rod is connected with the handle, while the lower end is connected with a pin shaft through screw threads; the upper part of the pin shaft is provided with a clamp nut, and the lower part of the pin shaft is connected with the end cover through pins; a valve rod is arranged inside the valve body, a plug hole is formed outside the valve body, and two ends of the valve body are connected with the end cover and a front cover thread respectively; and a spring, a stroke gasket and a retainer ring are arranged in the end cover. The integral multi-way reversing valve has the following advantages that: an oil inlet valve body, a reversing valve body and an oil return valve body are integrated by adopting an integral casting process, and small mass, simple appearance and smooth transition of the cavity of the valve enable a complex flow passage not to affect the pressure loss of liquid so as to well control the loss of oil pressure, shorten the time of hydraulic oil flowing through the valve body and ensure the purity of the hydraulic oil; castings have good compactness and high bearing pressure; and the problem of leakage between sheets of a sheet valve does not exit.

Owner:WUHAN LAZY CAT TECH

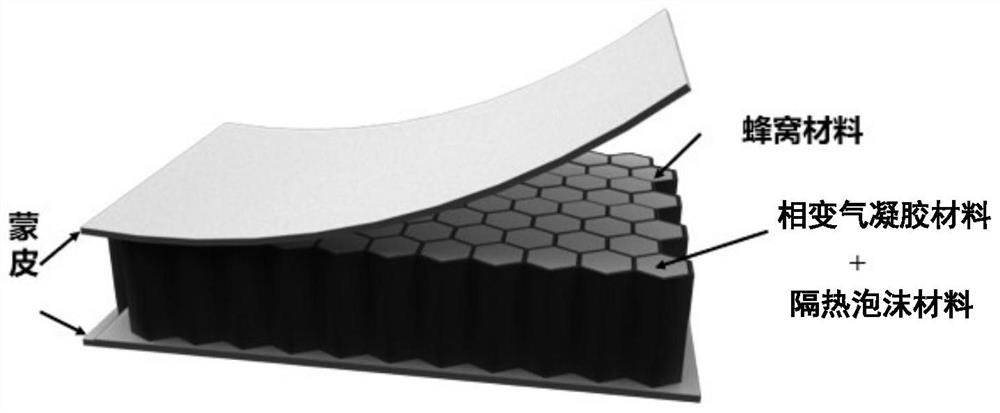

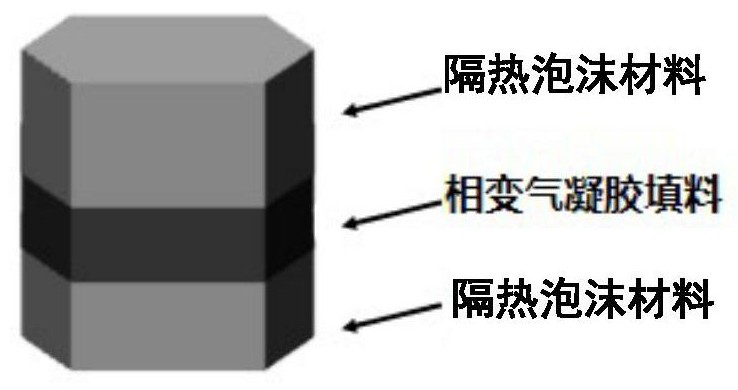

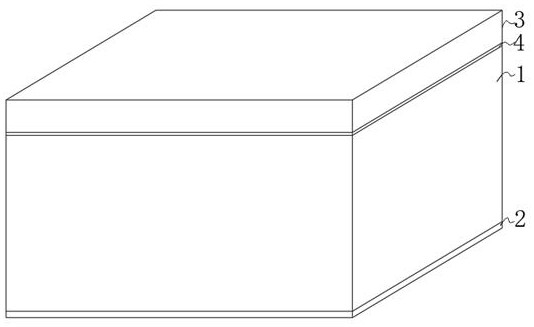

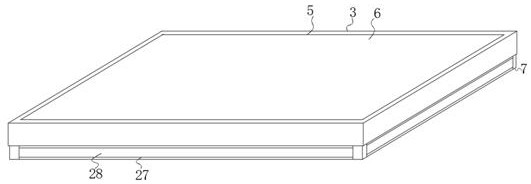

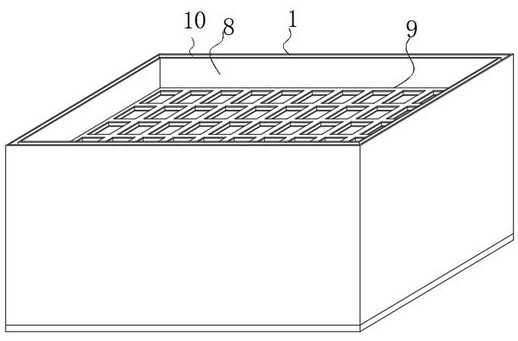

Aerogel-containing phase-change energy-storage thermal-insulation board, preparation method and application thereof

PendingCN113400739ALow densityNo leakage issuesClimate change adaptationSynthetic resin layered productsBoard structureAerogel

The invention discloses an aerogel-containing phase-change energy-storage thermal-insulation board, a preparation method and application thereof. The phase-change energy-storage thermal-insulation board comprises a core board structure and a skin layer structure, wherein the core board structure comprises a uniform porous material serving as a reinforcing phase and a filling layer distributed in the uniform porous material in a filling mode, the filling layer comprises a phase-change aerogel filler and a thermal-insulation material, and the phase-change aerogel filler comprises an aerogel material with a uniform porous structure and a phase-change material filled and distributed in the pore channels of the aerogel material. According to the invention, the phase-change material and the aerogel material are combined, and the phase-change material can be limited by using the extremely strong capillary action force of the nano-scale pore channel, so that the leakage of the phase-change material and the adverse effect caused by non-uniform distribution of the phase-change material when the phase-change behavior occurs are avoided; and due to the extremely low density of the aerogel, the density of the phase-change energy-storage thermal-insulation board can be greatly reduced, so that the density of the phase-change energy-storage thermal-insulation board has a great application prospect in the fields of industrial and building heat insulation, military and aerospace, composite materials and the like.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

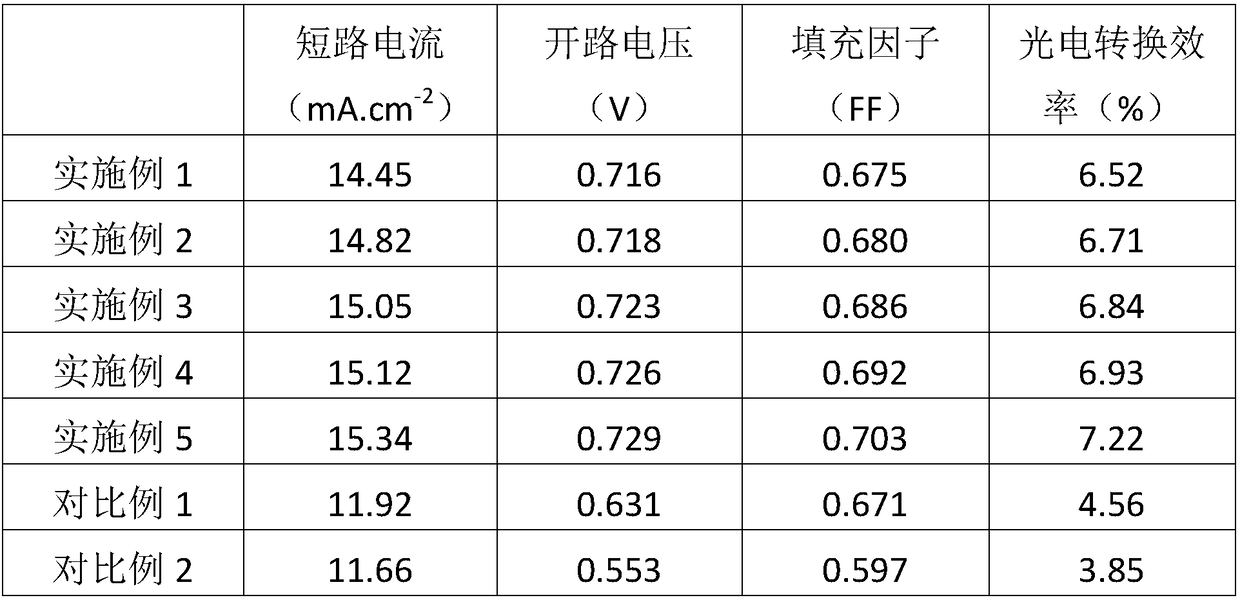

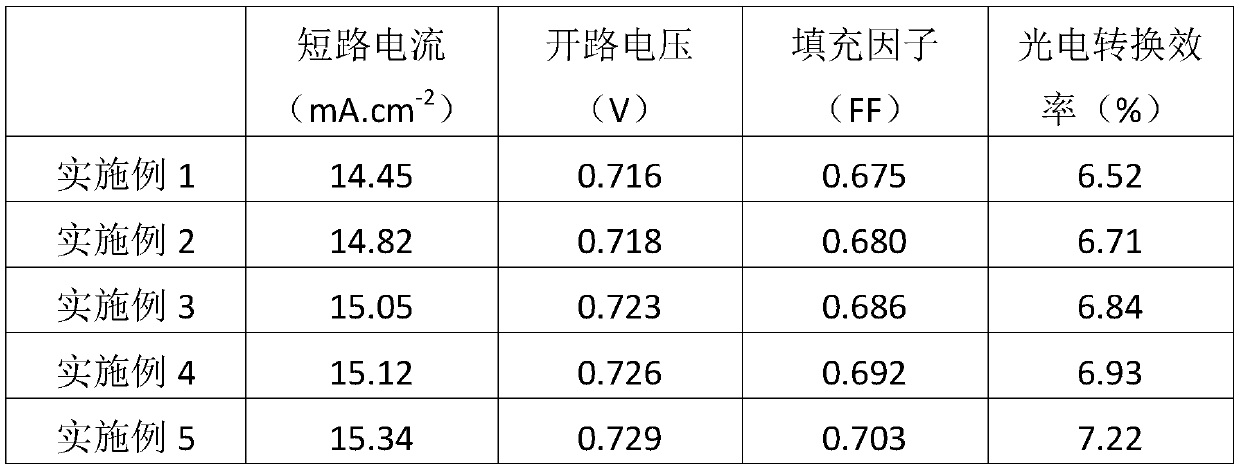

Solid electrolyte for dye-sensitized solar cell based on ionic crystal

ActiveCN108320912AImprove job stabilityGood conductivityLight-sensitive devicesPhotovoltaic energy generationIonic crystalDye-sensitized solar cell

The present invention discloses a solid electrolyte for a dye-sensitized solar cell based on ionic crystal. The solid electrolyte comprises the following components, part by weight: 40-50 parts of cyanoimidazole ionic crystal, 3-7 parts of (4-ferroceneacetenyl) aniline modified fullerene, 5-10 parts of elemental iodine and 5-10 parts of additive. The additive is one or more than one of MBI, NBB and TBP. Compared to the prior art, the solid electrolyte for a dye-sensitized solar cell based on ionic crystal provided by the invention is higher in conductivity, better in stability, easy to package, free of organic solvent, better in safety, and more efficient for improvement of the photoelectric conversion efficiency and the work stability of the dye-sensitized solar cell.

Owner:HUNAN CHENLI NEW MATERIAL CO LTD

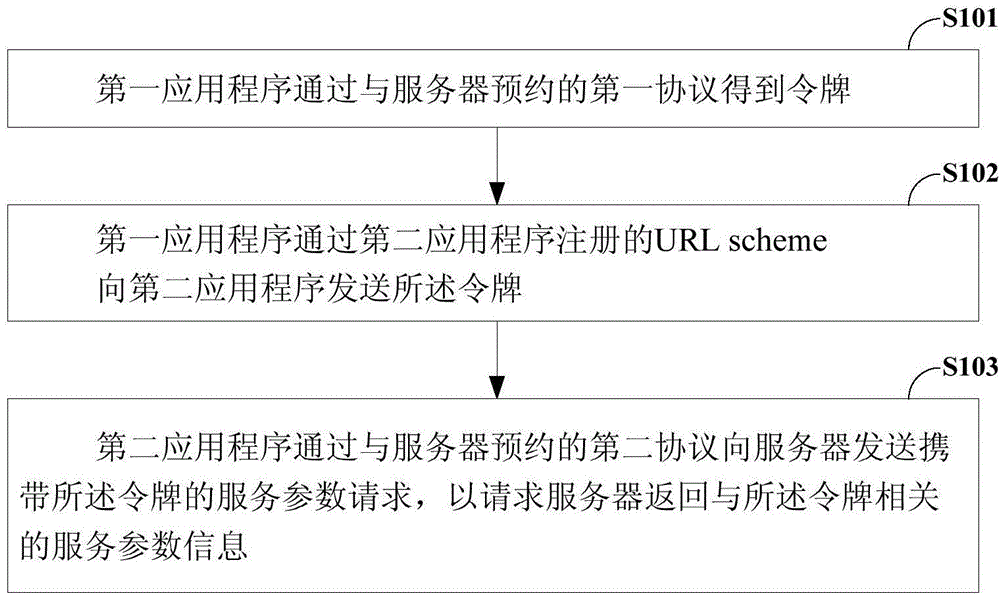

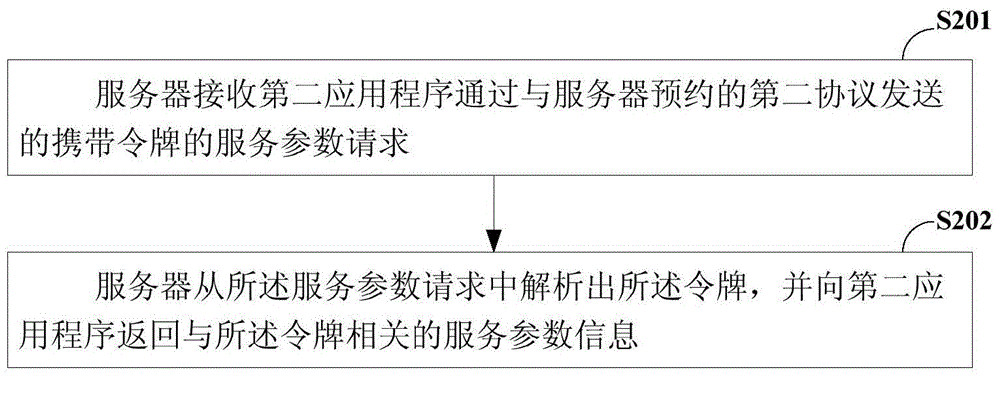

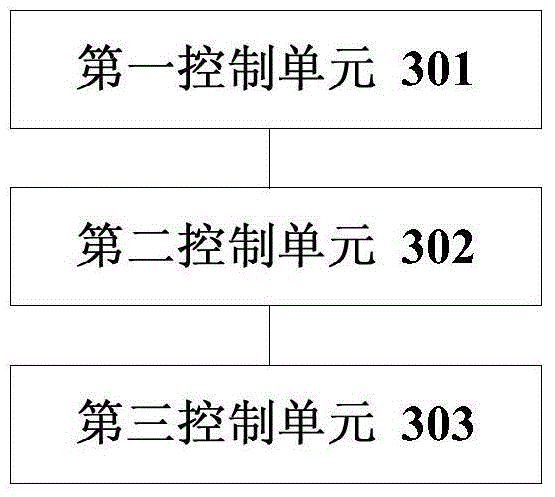

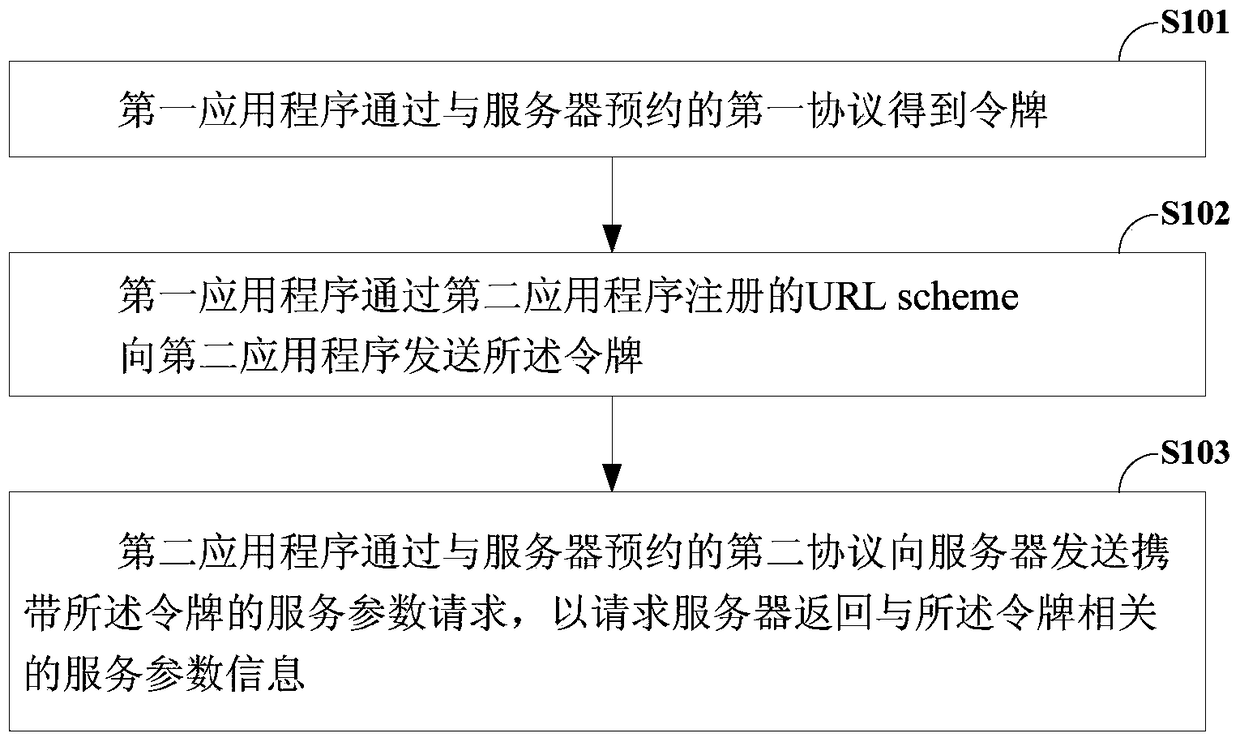

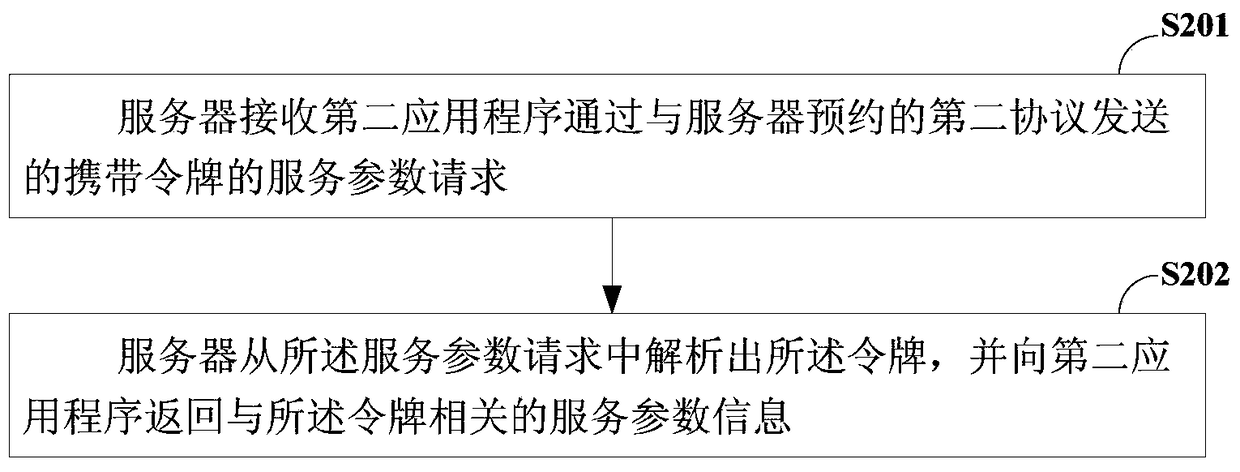

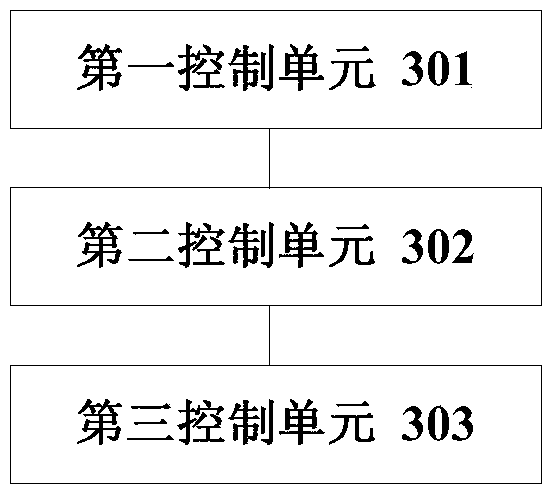

IOS platform scheme transmitting method, device and system and server

ActiveCN106156601ANo leakage issuesEnsure safetyInterprogram communicationDigital data authenticationApplication softwareUniform resource locator

The invention provides an iSO platform scheme transmitting method, device and system and a server. The method comprises the steps that a first application program obtains a token through a first protocol ordered by the first application program for the server; the first application program sends the token to a second application program through the URL scheme registered by the second application program; the second application program sends a service parameter request with the token through a second protocol ordered by the second application program for the server so as to request the server to return service parameter information relevant to the token. The server is introduced, so that only the token rather than parameter information is directly transmitted between the application programs, a hacker can only intercept the token and cannot directly obtain parameter information under the transmission mechanism even if forging application programs, the hacker cannot obtain parameter information by being ignorant of participation of the server and incapable of obtaining protocol content, and therefore information leakage can be prevented.

Owner:ALIBABA (CHINA) CO LTD

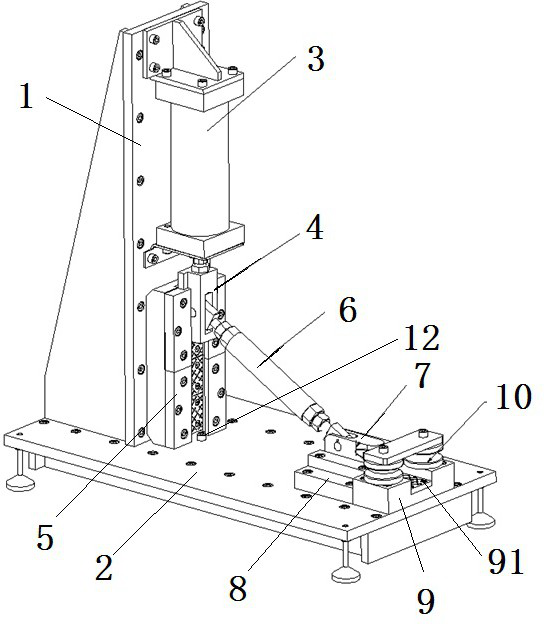

Workpiece bending device

PendingCN112547873AMeet production needsRequirements for small output forceMetal-working feeding devicesPositioning devicesEngineeringStructural engineering

The invention relates to a workpiece bending device. The workpiece bending device comprises a first guide seat and a second guide seat, wherein a first sliding block and a second sliding block are assembled on the first guide seat and the second guide seat respectively in a guiding mode; a driving device is arranged on the first guide seat; a pushing head is arranged on the second sliding block; aconnecting rod is arranged between the first guide seat and the second guide seat; the connecting rod has a stress application state in a moving process; an included angle between the connecting rodand the second guide seat is smaller than 45 degrees when the connecting rod is in the stress application state; when the included angle between the connecting rod and the second guide seat is smallerthan 45 degrees, the thrust of the connecting rod to the second sliding block is greater than that of the first sliding block to the connecting rod; the thrust borne by the pushing head can be greater than the output force of the driving device through the connecting rod; and when the bending force needed when bending a workpiece is not changed, the requirement on the output force of the drivingdevice of the workpiece bending device is low. The workpiece bending device can meet the production requirements of workpieces needed to be bent; and the mechanized operation is achieved.

Owner:HENAN SENYUAN ELECTRIC CO LTD

Method for constructing flexible super capacitor

ActiveCN105810448AShort timeLess consumablesHybrid capacitor electrolytesHybrid capacitor electrodesComposite filmManganese

The invention provides a method for constructing a flexible super capacitor. The method comprises the following steps: adding graphite oxide in deionized water according to a mass ratio of the graphite oxide to the deionized water of 0.5-2: 1000, and magnetically stirring or manually shaking for 0.5-1h to obtain a product A; stewing the product A at a temperature of 60-80 DEG C for 0.5-1h until a complete graphite oxide film is formed on the surface of graphite oxide hydrosol to obtain a product B; using a flexible film as a substrate, depositing the product B on the substrate, and drying to obtain a product C; soaking the product C in a hydrogen iodide solution with a mass percent of 55-85%, reducing for 3-48h at 15-80 DEG C, and cleaning to obtain a product D; and soaking the product D in 0.5-5mM potassium permanganate for 5-48h, and cleaning to obtain a product E, namely a graphene / manganite composite film deposited on the flexible substrate is obtained. The capacitor constructed by the method is good in electrochemical performance, and a traditional sandwich type flexible super capacitor can also be constructed, and meanwhile, the method is beneficial for the miniaturization and lighting and thinning of devices.

Owner:GUIZHOU UNIV

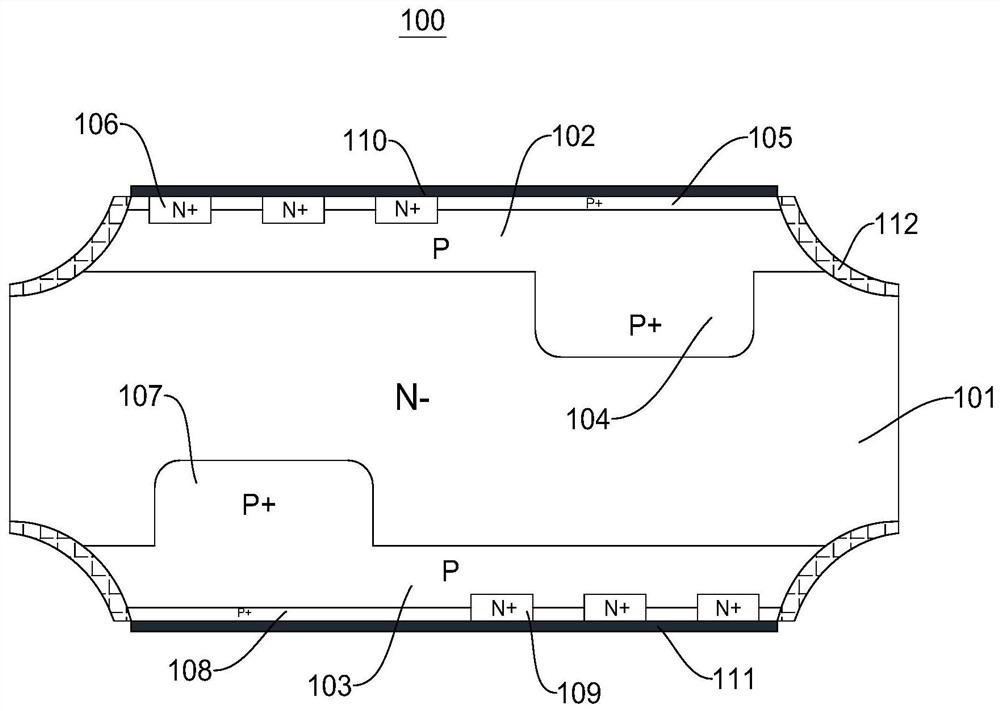

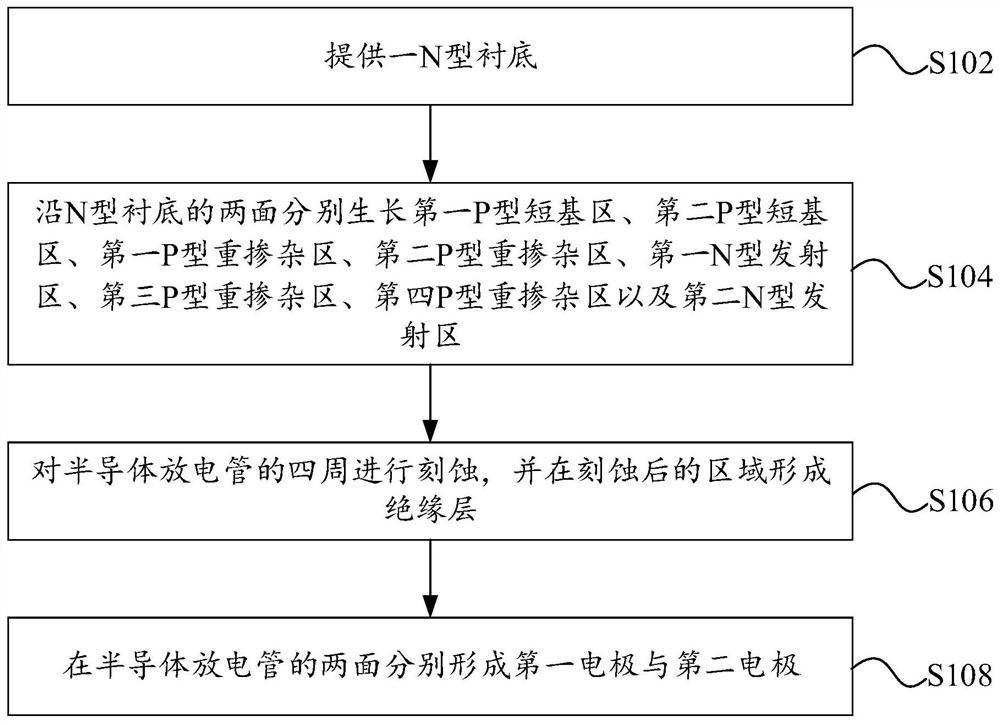

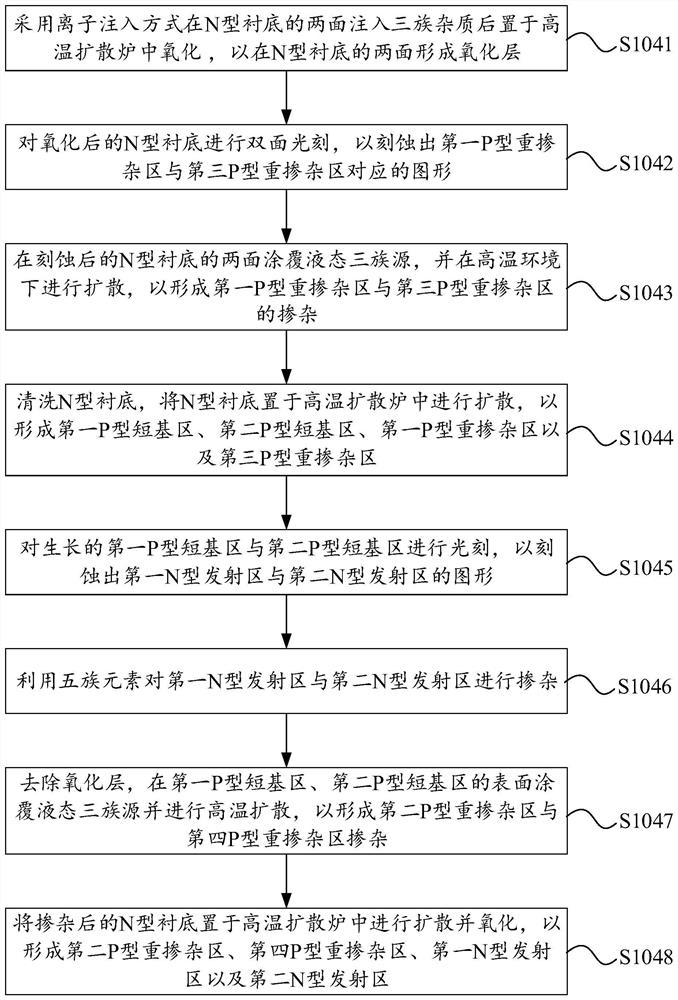

Semiconductor discharge tube and manufacturing method thereof

PendingCN112133744ANo leakage issuesSmall discreteSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductorMaterials science

The invention provides a semiconductor discharge tube and a manufacturing method thereof, and relates to the technical field of semiconductor power devices. The semiconductor discharge tube comprisesan N type substrate, a first P type short base region, a second P type short base region, a first P type heavily doped region, a second P type heavily doped region, a third P type heavily doped region, a fourth P type heavily doped region, a first N type emitter region, a second N type emitter region, a first electrode, a second electrode and an insulating layer. The semiconductor discharge tube and the manufacturing method thereof have the advantages of being small in voltage discreteness, long in service life and low in residual voltage.

Owner:捷捷半导体有限公司

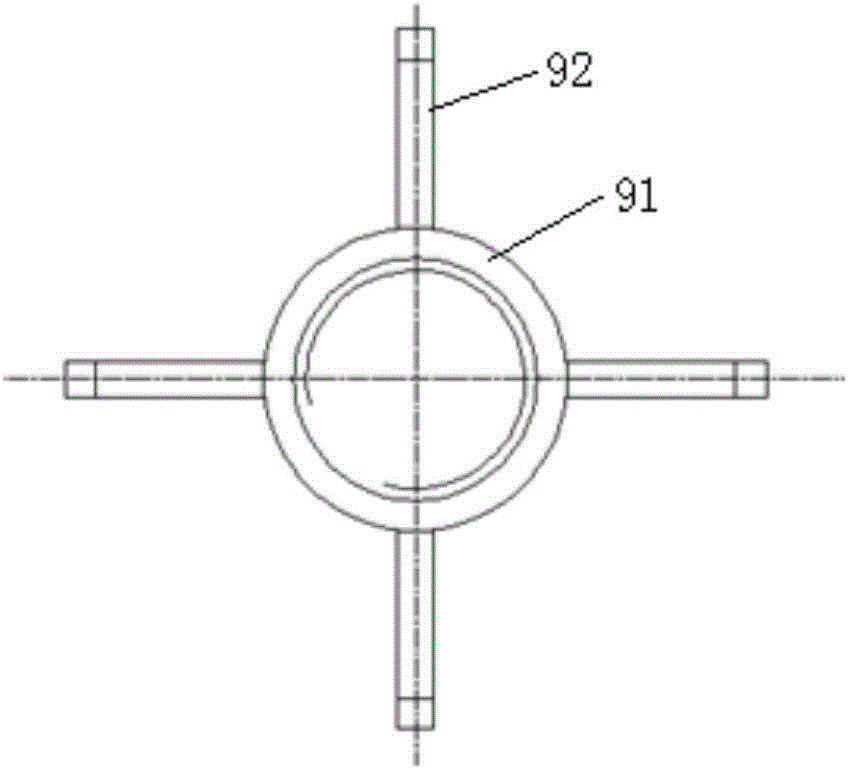

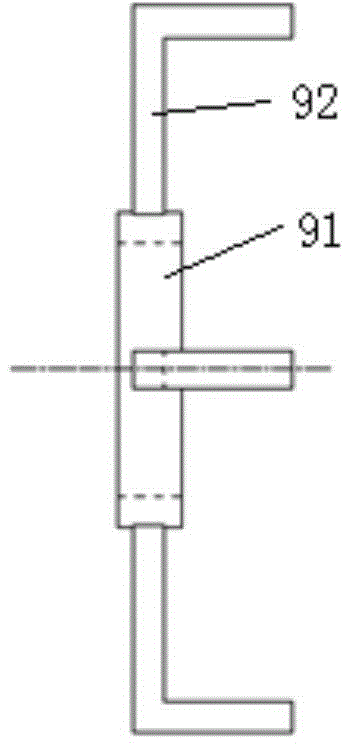

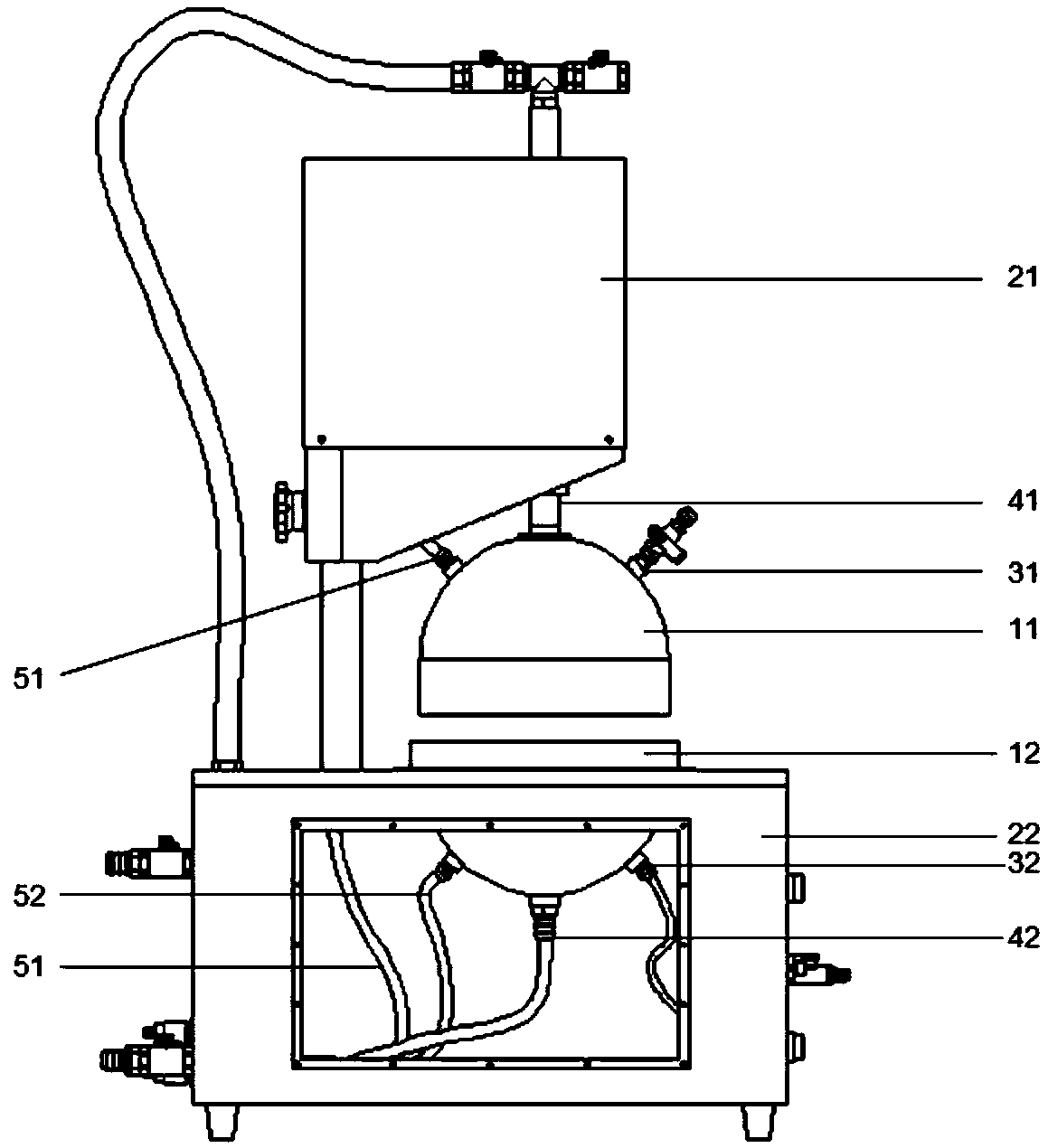

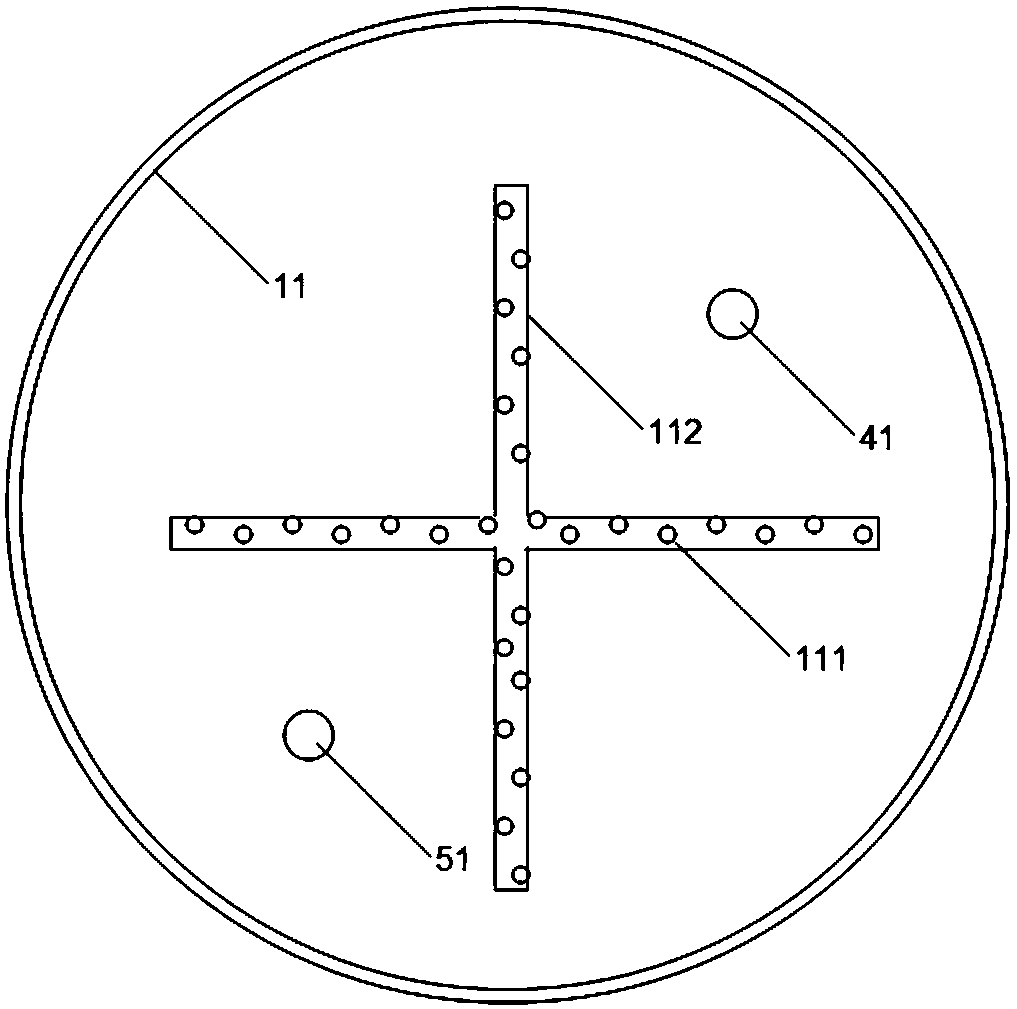

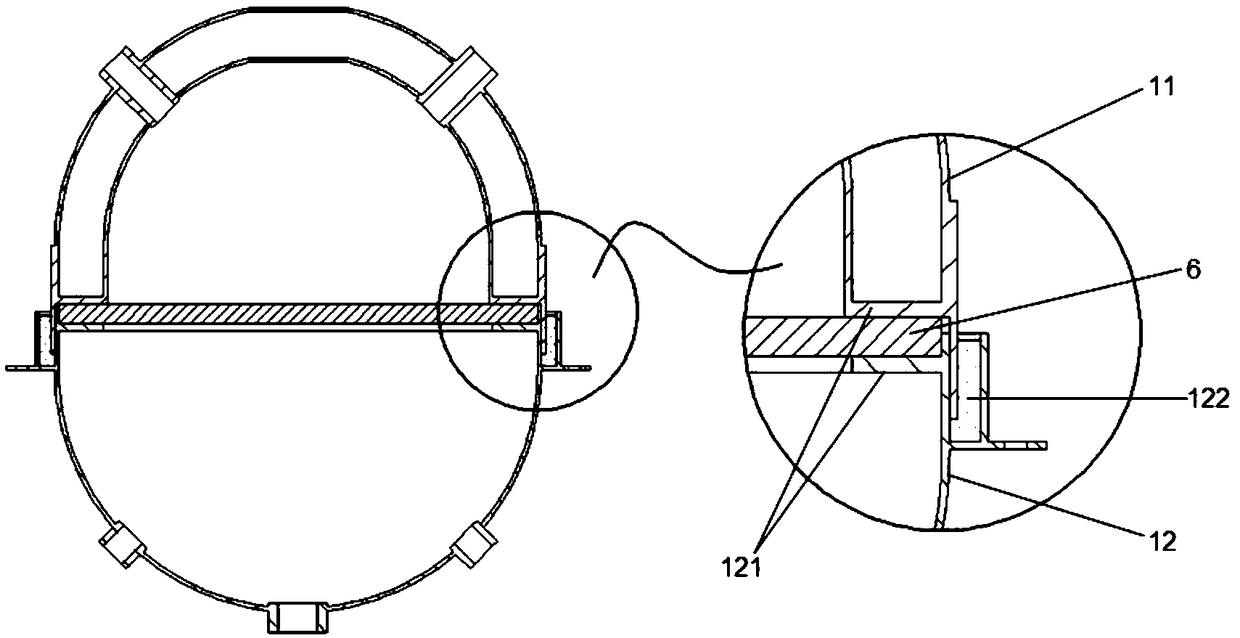

Testing device for air purification material and detection method for purification efficiency of air purification filter material

PendingCN109406654AImprove sealingImprove accuracyComponent separationPermeability/surface area analysisEngineeringFilter material

The invention aims to provide a testing device for an air purification material and a detection method for the purification efficiency of an air purification filter material. The testing device comprises a shell, wherein a clamping device is arranged on the inner wall of the shell; the clamping device is annularly closed, and the outer edge of the clamping device is fixedly connected with the inner wall of the shell; the clamping device divides the shell into two parts, one part is provided with a sample inlet, and the other part is provided with a discharge port; and the testing device is a closed space when the sample inlet and the discharge port are closed. The detection method comprises the steps that the air purification filter material is arranged on the clamping device; polluted gasis input into a feed port; the polluted gas and purified gas are collected, the concentration of harmful gas is detected, and the purification efficiency is calculated. The method is used for evaluating the purification capability and the purification effect of the air purification material and has the advantages that the stability is high, the system leakproofness is good, the detection data forthe purification efficiency of the air purification filter material is accurate, and the repeatability and reproducibility are very good.

Owner:CHINA TEST & CERTIFICATION INT GRP CO LTD

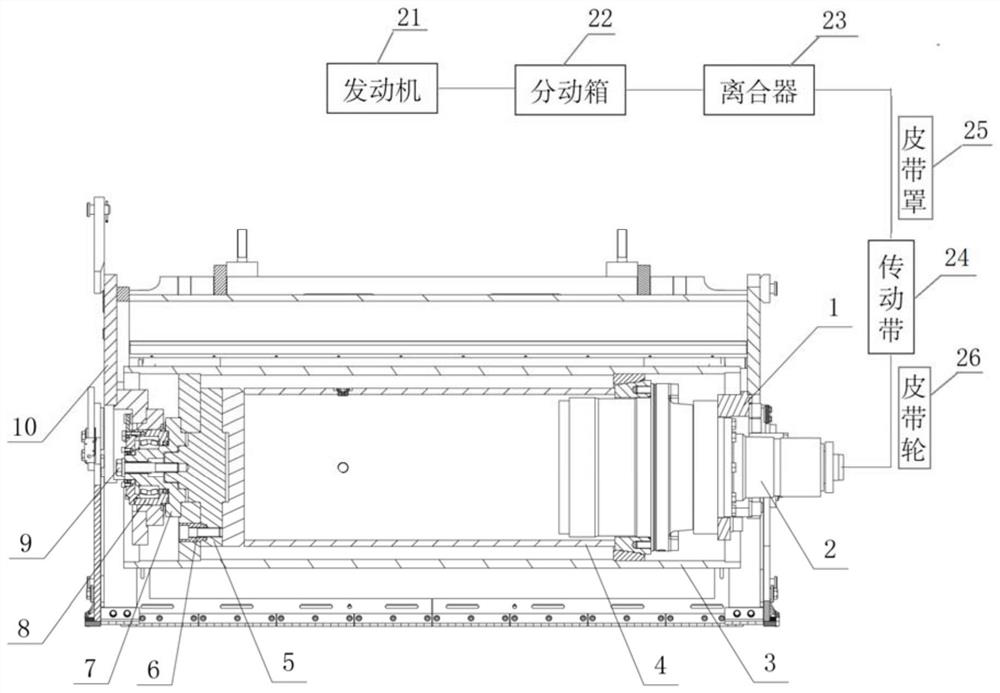

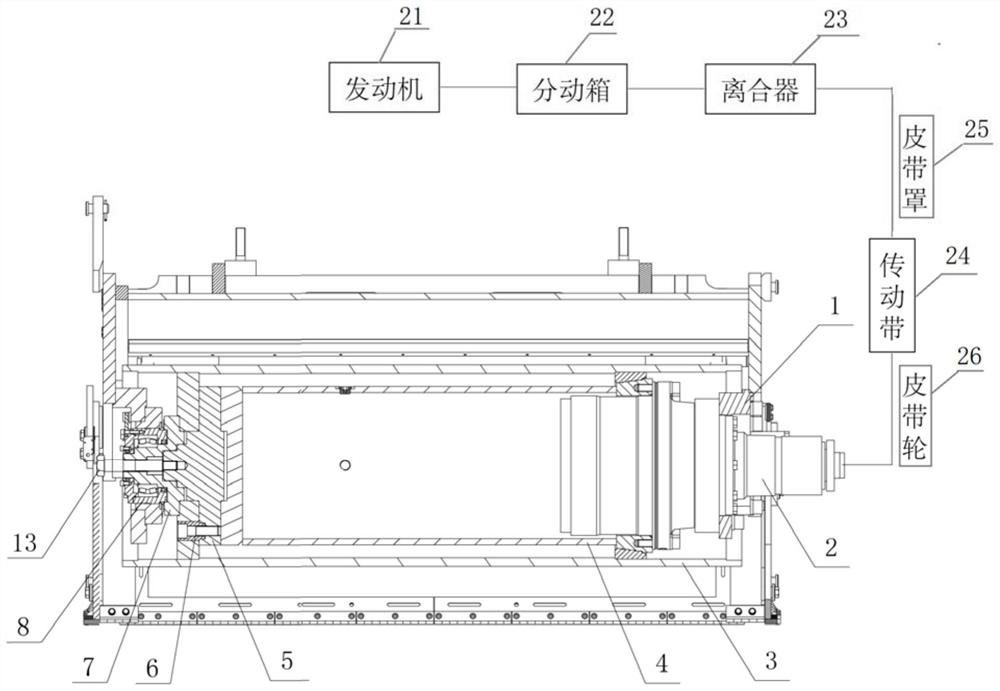

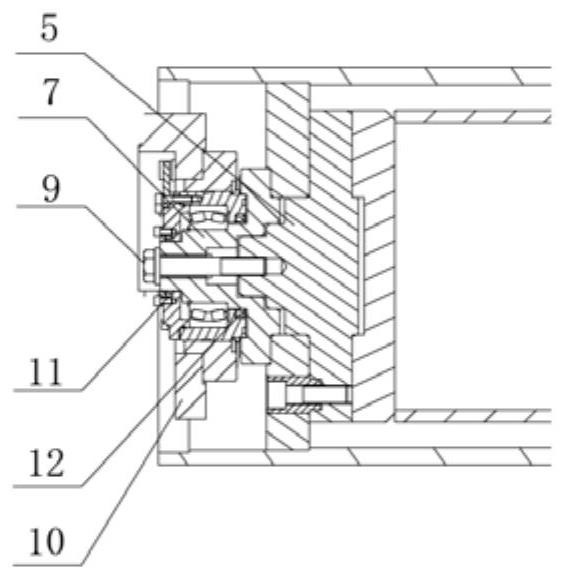

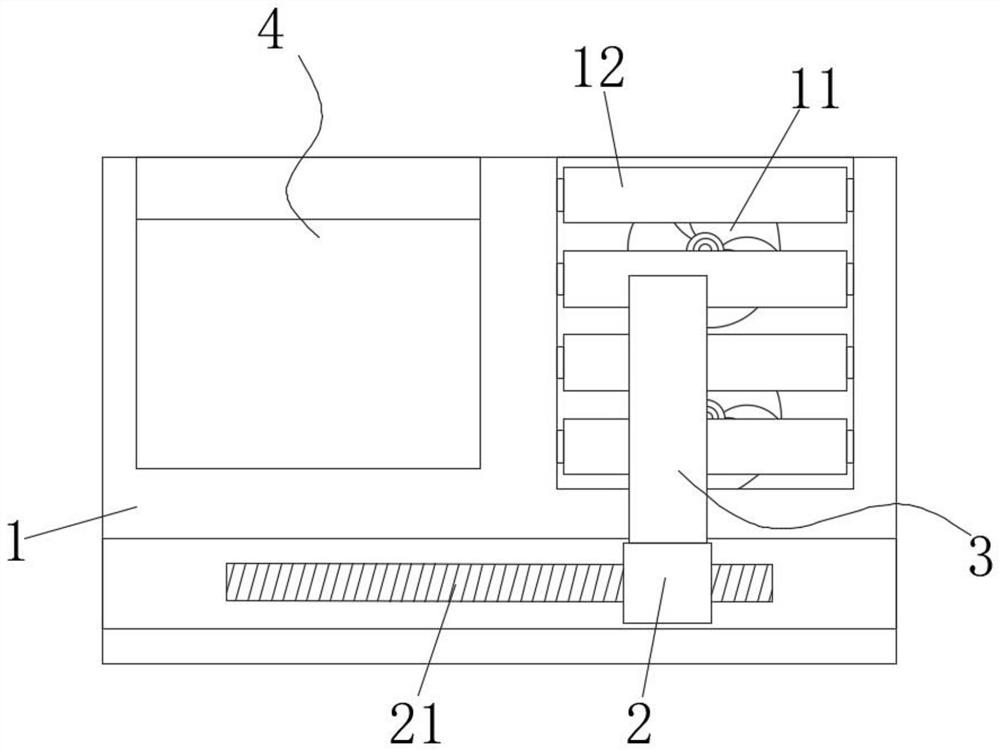

Milling drum quick-changing structure, milling machine and using method of milling drum quick-changing structure

PendingCN114319050AEasy to replaceEliminate the verification processRoads maintainencePavement maintenanceReducer

The invention relates to a milling drum quick-changing structure, a milling machine and a using method of the milling drum quick-changing structure, and belongs to the field of pavement maintenance operation construction equipment. The milling drum quick-change structure comprises a box body, a speed reducer, a milling drum and an internal support body, the milling drum is arranged in the box body through an internal support body; the internal supporting body comprises a supporting cylinder, a flange plate and a shaft end assembly. One end of the supporting cylinder is a closed end, and the closed end is connected with the flange plate; the other end of the supporting cylinder is an open end, and the open end is connected with the moving end of the speed reducer to form a closed inner cylinder cavity. The shaft end assembly is connected with the milling drum and the flange plate through the connecting seat; the whole process of replacing the milling drum is simple and efficient, and the labor intensity is greatly reduced.

Owner:SHANTUI CONSTR MASCH CO LTD

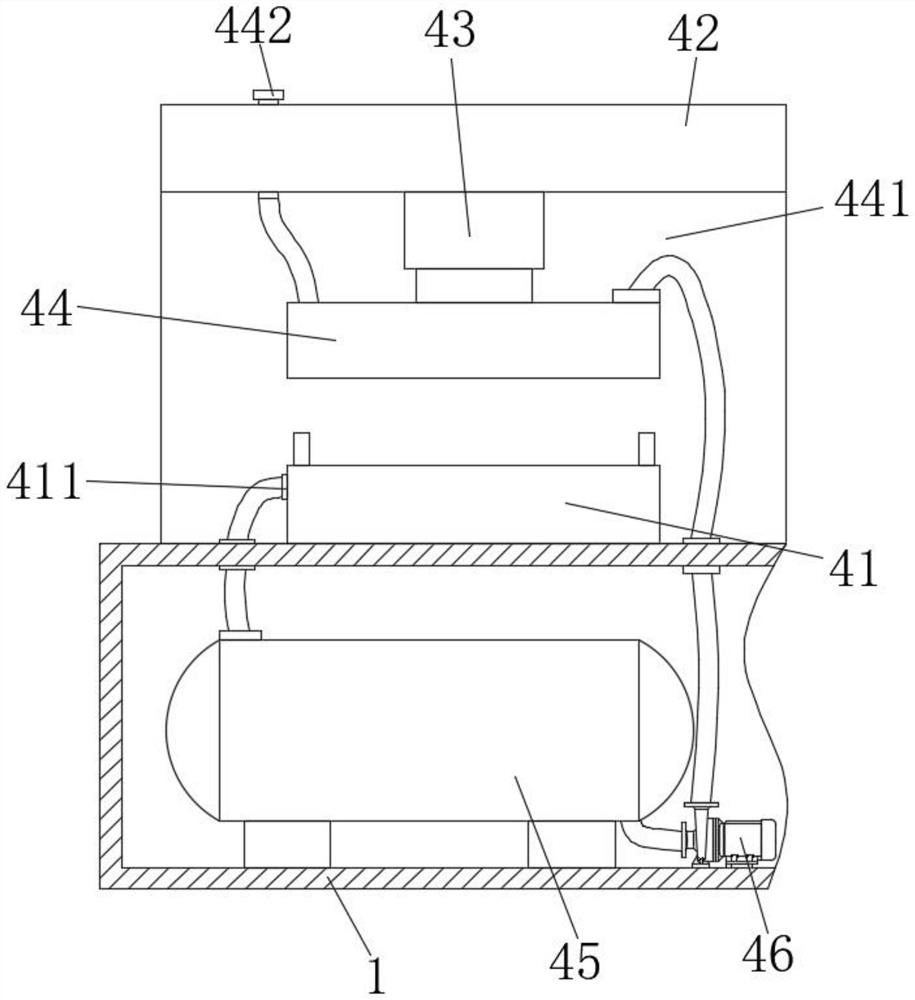

Rapid cooling system for automobile plastic part injection mold and working method of rapid cooling system

The automobile plastic part injection mold rapid cooling system comprises a machine body, a stand column is slidably arranged on one side of the machine body, a translation assembly is arranged on one side of the top end of the stand column, and an injection molding assembly is arranged at one end above the machine body; the injection molding assembly comprises a mold frame fixedly arranged on the machine body, a lower mold fixedly arranged on the machine body and a cooling water tank arranged in the machine body, the cooling water tank can circulate water in the cooling water tank under the action of a circulating water pump, and cold water sequentially passes through an upper mold and the lower mold and flows back into the cooling water tank; it needs to be explained that when the circulating water pump is started, after injection molding is completed, namely, cooling work is carried out in the state that the upper mold and the lower mold are not separated, when the upper mold and the lower mold are attached, a cooling loop just forms a closed loop, and therefore the problem of cooling water leakage cannot occur in the cooling process; and the cooling effect is ensured.

Owner:昆山智勇模具有限公司

Preparation method and application of (4-ferroceneethynyl)aniline modified fullerene

InactiveCN109988196AImprove job stabilityNo leakage issuesLight-sensitive devicesPhotovoltaic energy generationBoiling pointEvaporation

The invention discloses a preparation method of (4-ferroceneethynyl)aniline modified fullerene. The method comprises the following steps: 1) preparing epoxy modified fullerene: dispersing amino modified fullerene into fatty alcohol, adding epichlorohydrin and potassium hydroxide into the mixture, performing a reflux reaction for 5-8 h under stirring at 70-80 DEG C, performing rotary evaporation toremove a solvent, performing centrifugal washing for 5-7 times by using water, placing the washed material into a vacuum drying oven at 100-110 DEG C, and performing drying to obtain the epoxy modified fullerene; and 2) preparing the (4-ferroceneethynyl)aniline modified fullerene: dispersing the epoxy modified fullerene into a high-boiling-point solvent, adding (4-ferroceneethynyl)aniline into the solvent, performing a reaction for 6-8 h under stirring at 70-80 DEG C, performing rotary evaporation to remove a solvent, and performing centrifugal washing for 6-8 times by using dichloromethane to obtain the (4-ferroceneethynyl)aniline modified fullerene. The (4-ferroceneethynyl)aniline modified fullerene provided by the invention can be applied to preparation of a dye-sensitized solar cell with high efficiency and high stability.

Owner:HUNAN CHENLI NEW MATERIAL CO LTD

Novel oil leakage prevention transmission shaft universal joint

ActiveCN111550501AExtended service lifeNo leakage issuesClutchesYielding couplingOil and greaseUniversal joint

The invention discloses a novel oil leakage prevention transmission shaft universal joint. The novel oil leakage prevention transmission shaft universal joint comprises a pressure relief device, a shell device, a transmission device, a shaft tube and a spline shaft lever, wherein the shaft tube is fixedly connected to the shell device; the pressure relief device and the transmission device are sequentially arranged in the shell device; the spline shaft lever is fixedly connected to the shell device; and by adopting the pressure relief device and eliminating a ventilating slot, the novel oil leakage prevention transmission shaft universal joint has the advantage that grease in the universal joint is prevented from leaking.

Owner:NINGBO GEELY AUTOMOBILE RES & DEV CO LTD +1

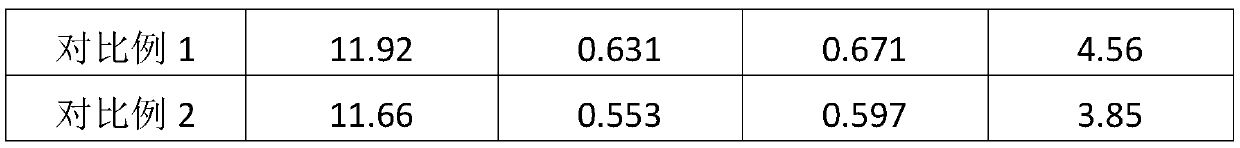

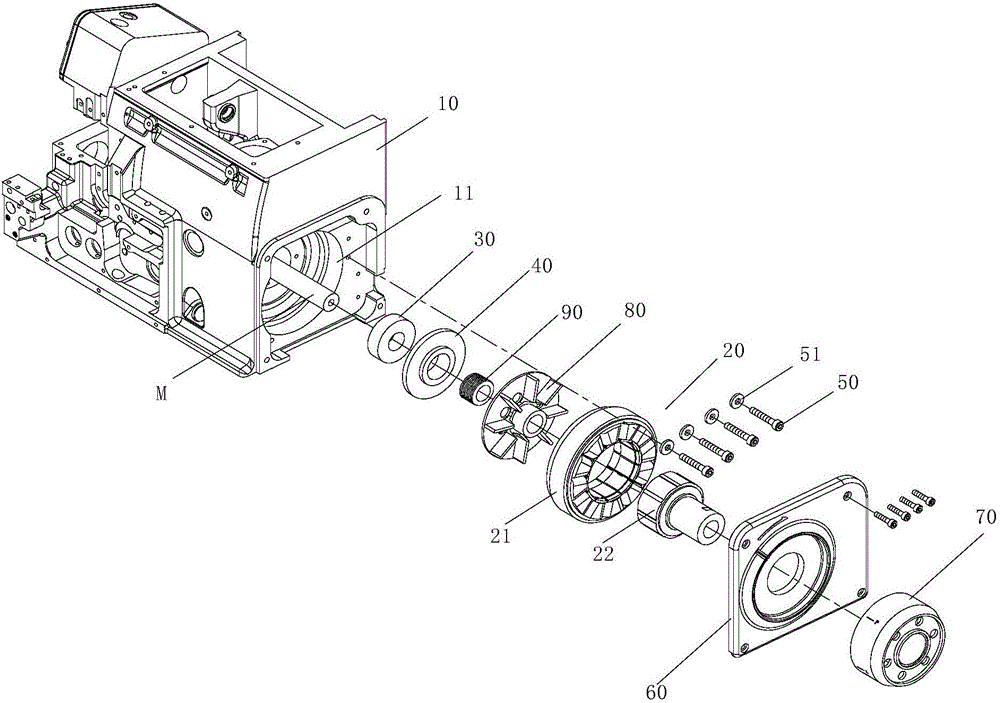

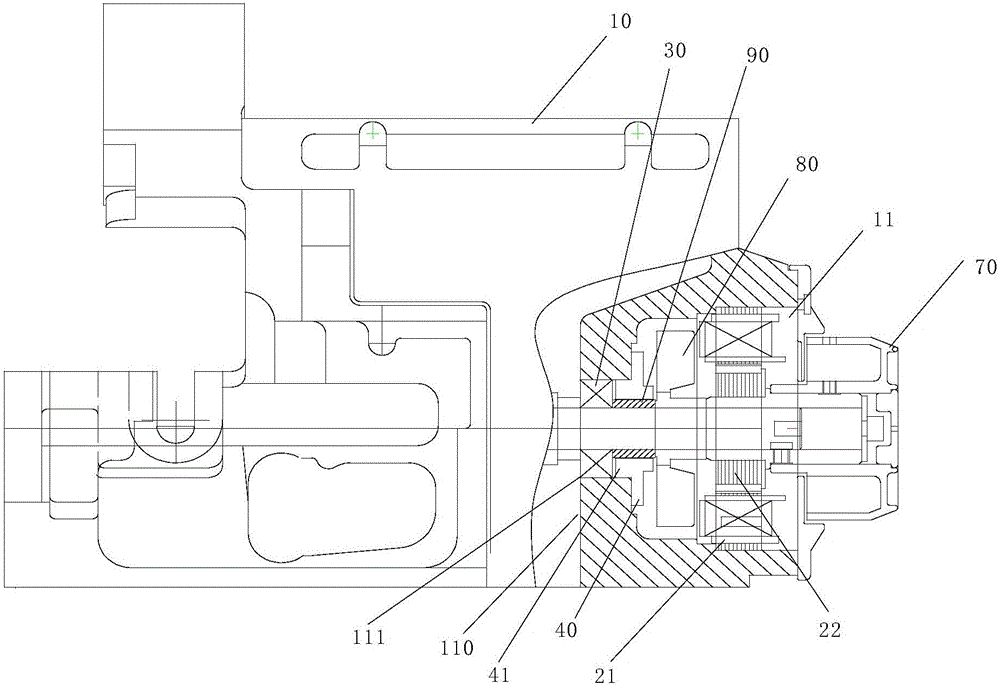

Industrial sewing machine with built-in stator winding

ActiveCN105755697ASmall footprintEasy to transportLubrication/cooling devicesSewing-machine control devicesMiniaturizationPulp and paper industry

The invention provides an industrial sewing machine with a built-in stator winding, wherein the industrial sewing machine is miniaturized and is low in cost. The industrial sewing machine is provided with a machine shell and a driving device embedded in the machine shell, the driving device is composed of the stator winding and a rotor, a containing chamber is integrally formed in the machine shell, an opening is formed in the position, at one end of the machine shell, of the containing chamber, a side cover is installed on the opening, the stator winding is fixed into a stator winding containing space of the containing chamber, and the rotor is located inside the stator winding and connected with a sewing machine main shaft which penetrates through a bearing installed in the chamber wall of the containing chamber and extends into the containing chamber. Due to the fact that the containing chamber is integrally formed in the shell, an electric motor serving as a power source can be arranged inside the machine shell of the industrial sewing machine, therefore no power source needs to be separately arranged outside the industrial sewing machine, the overall occupied area of the industrial sewing machine is decreased, the industrial sewing machine is integrally miniaturized, it is convenient to transport and install the industrial sewing machine, and cost of the industrial sewing machine is lowered.

Owner:TIANJIN HUATANG SEWING MACHINE MFG

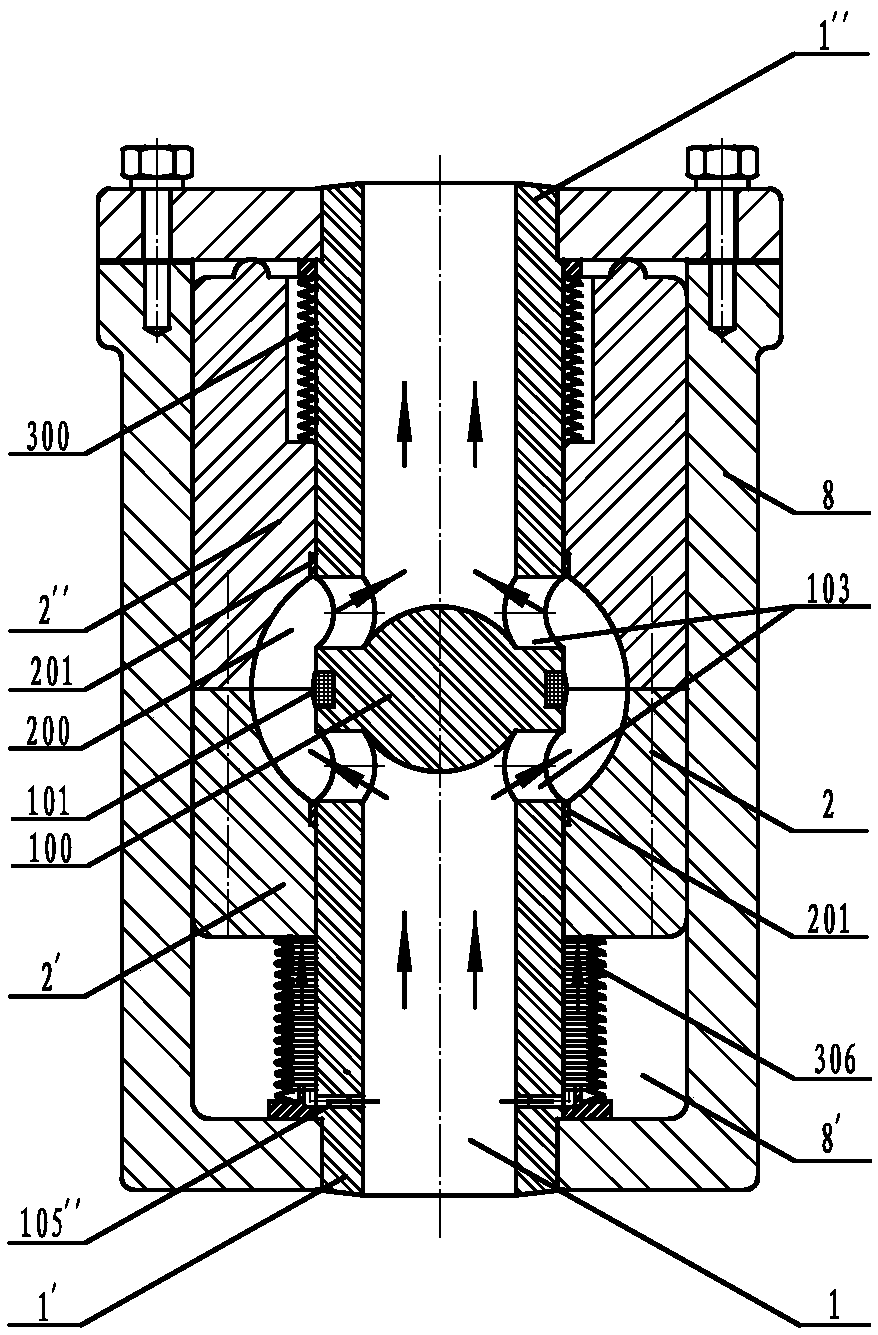

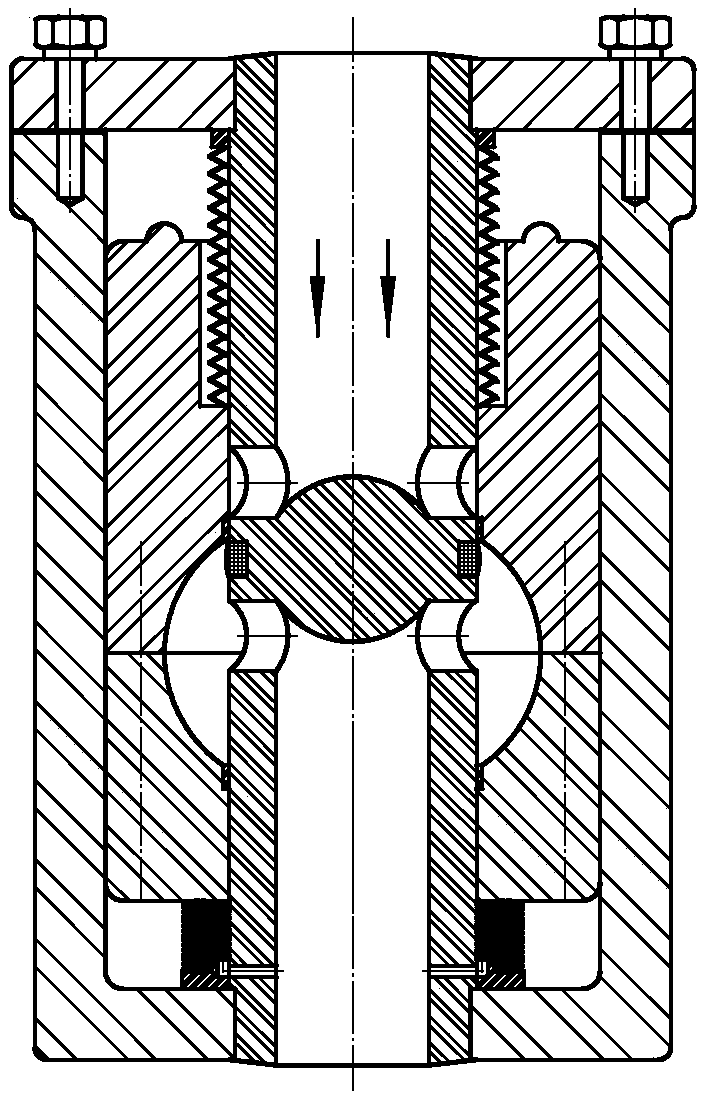

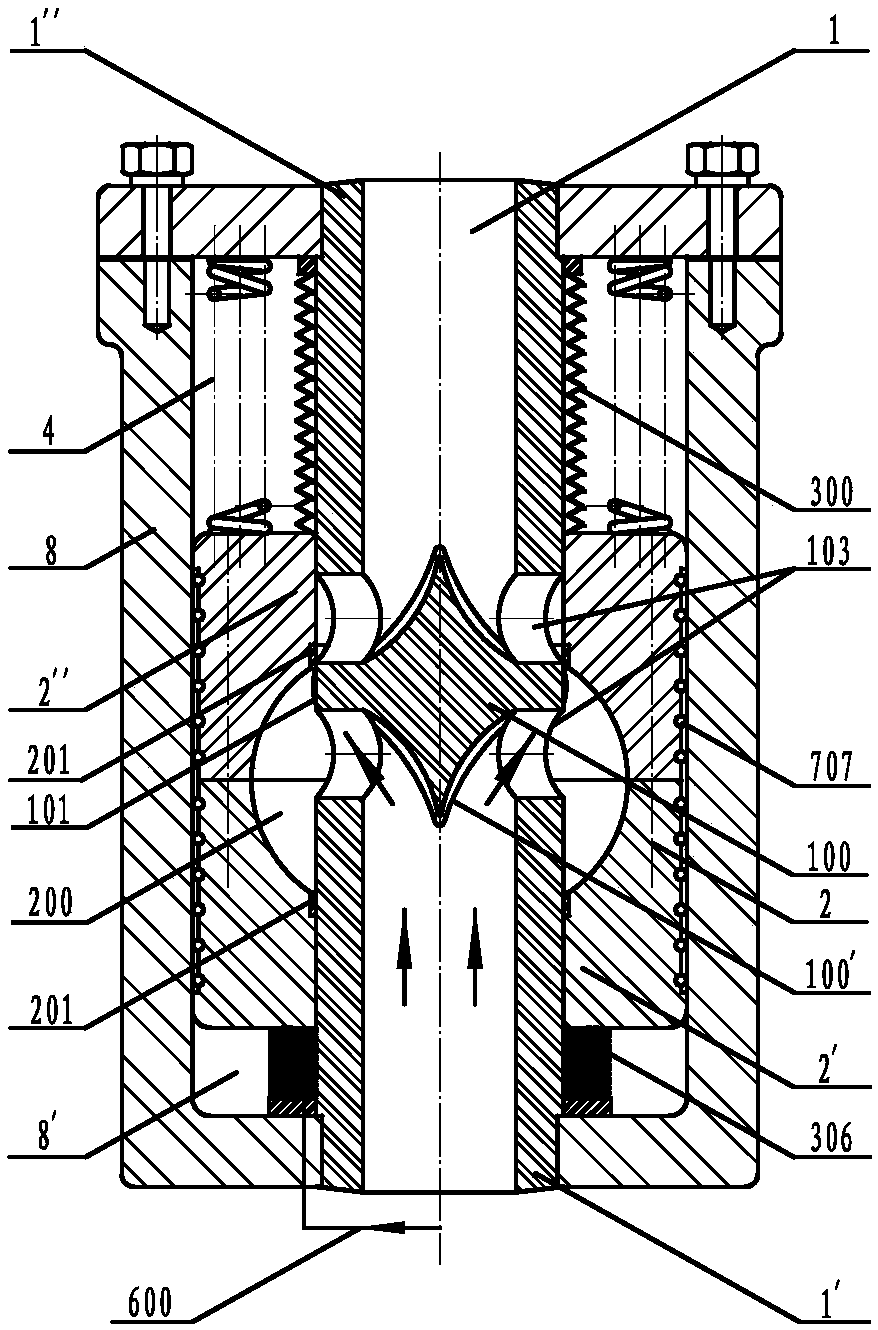

Drive core pipe valve of dual valve body bellows pressure cabin

The invention provides a drive core pipe valve of a dual valve body bellows pressure cabin, and relates to pressure opening and closure, pulse, non-return, safety, regulation, pressure reduction, emergency shutoff and the like; a valve core pipe wrapped in an inner cavity of an outer valve body serves as a fixing piece to coaxially penetrate a sleeve I of a valve body, an inner cavity of the valvebody and a sleeve II of the valve body; the middle part of the valve core pipe is provided with an axial interlayer, and the two adjacent axial sides of the interlayer are each provided with at leastone radial circulation hole of an input section and an output section; a sealing pair is formed by an annular valve element surrounding the interlayer, and an annular valve seat of at least one sleeve throat of the sleeve I and the sleeve II; the input section and the sleeve I as well as the output section and the sleeve II are cooperated in an axle hole mode, and the joint parts are provided with seals; and the joint part between the input section and the sleeve I is provided with the bellows pressure cabin, and the bellows pressure cabin and a front pressure cavity of the valve are throughby manes of a channel. Under the effect of potential energy in two directions, the valve body does axial reciprocating motion in the inner cavity of the outer valve body so that the effects of openingand closure and function switching are achieved. The drive core pipe valve is safe, reliable, leak-free and multipurpose.

Owner:卢星霖

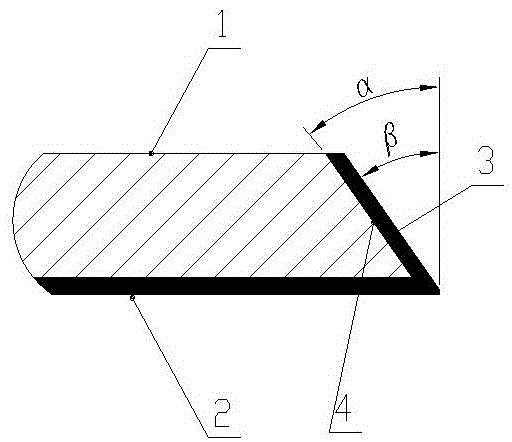

Bi-metal pipeline and pipe fitting beveling method and bi-metal pipeline and pipe fitting assembly

InactiveCN105583582AGuaranteed operational safetyAvoid Weld LeakageRigid pipesWorkpiece edge portionsPipe fittingCarbon steel

A bi-metal pipeline and pipe fitting beveling method is used for a bi-metal pipeline and a bi-metal pipe fitting. The bi-metal pipeline and the bi-metal pipe fitting each comprise a base layer and a composite layer. Each base layer is made of one of carbon steel, alloy steel and stainless steel. Each composite layer is made of nickel-based alloy or stainless steel. The beveling method comprises the first step that primary beveling is conducted on the base layer and the composite layer of the end face of the bi-metal pipeline or the bi-metal pipe fitting, and the end face is called a beveled end face after primary beveling. The problem of circular seam leakage caused by misalignment can be solved, and the circular seam installation quality is guaranteed.

Owner:ZHENGZHOU WANDA HEAVY IND CO LTD

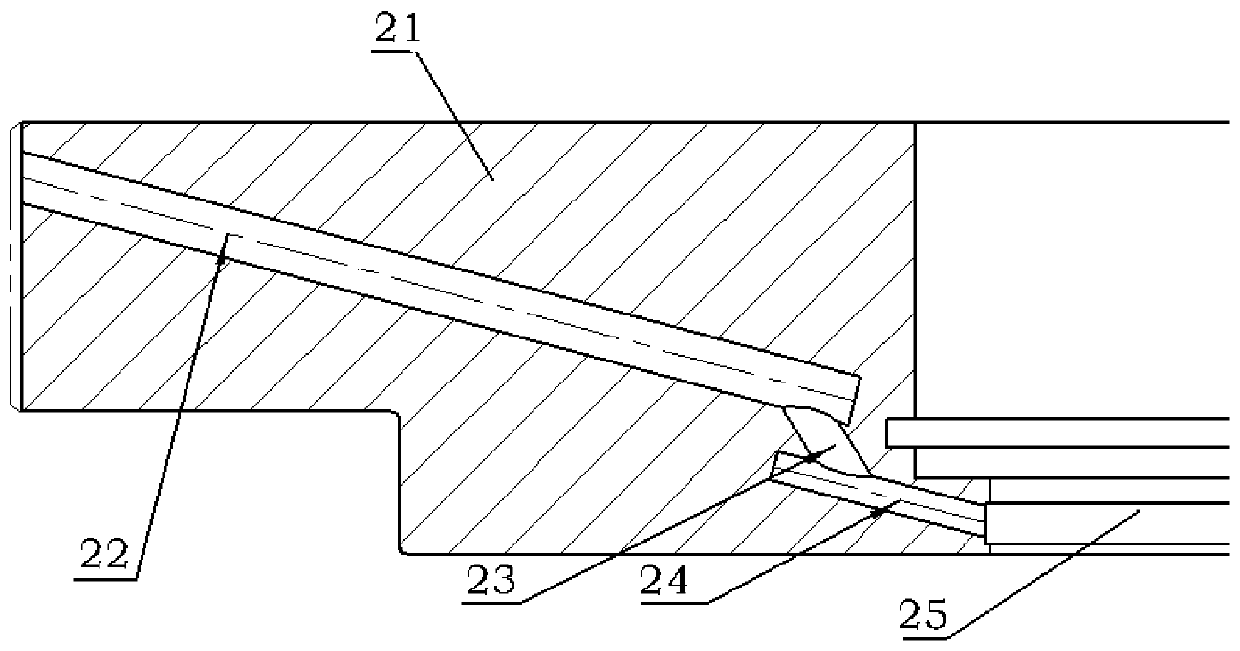

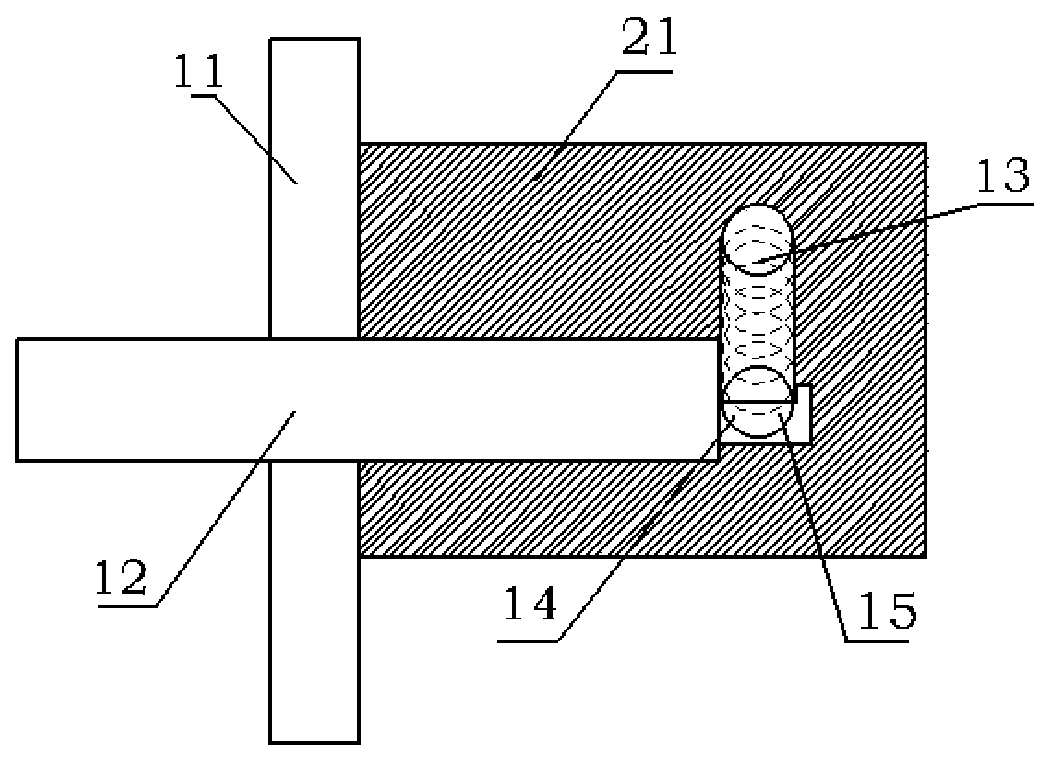

End Cover Structure and Processing Method for Preventing Working Gas Leakage of Vertical Split Compressor

The invention discloses an end cover structure for preventing working gas leakage of a vertically split compressor, comprising an end cover main body, an air inlet hole, a connecting hole and a dry gas sealing hole arranged on the end cover main body, the air inlet The hole communicates with one end of the connecting hole, the other end of the connecting hole communicates with the dry gas sealing hole, and the dry gas sealing hole communicates with the dry gas sealing area. The invention also discloses a processing method of the end cover structure preventing the leakage of the working gas of the vertically split compressor, and a compressor including the end cover structure preventing the leakage of the working gas of the vertically split compressor. The end cover structure for preventing the leakage of the working gas of the vertically split compressor and the processing method thereof provided by the present invention can prevent the working medium in the compressor from leaking from the connecting hole of the end cover structure for preventing the leakage of the working gas of the vertically split compressor , and the end cover structure that prevents the leakage of the working gas of the vertically split compressor has high processing efficiency and low processing cost.

Owner:SHENYANG TURBO MASCH CORP

Thermoplastic polyethylene glycol-based phase change energy storage material as well as preparation method and application thereof

ActiveCN113880997AFast curing molding speedEasy to prepareEnergy storageHeat-exchange elementsPolymer scienceLiquid state

The invention belongs to the technical field of phase change energy storage materials, and particularly relates to a thermoplastic polyethylene glycol-based phase change energy storage material as well as a preparation method and application thereof. The method comprises the following steps: dissolving high-molecular-weight solid-state mono-acrylic acid esterified polyethylene glycol, an initiator and a nano heat-conducting filler dispersion liquid in low-molecular-weight liquid-state mono-acrylic acid esterified polyethylene glycol according to a mass ratio, and uniformly conducting stirring to obtain a phase change energy storage material precursor; and curing and molding the precursor to obtain the thermoplastic polyethylene glycol-based phase change energy storage material. The raw material selected for preparing the thermoplastic polyethylene glycol-based phase change energy storage material is mono-acrylic acid esterified polyethylene glycol with different molecular weights, and the molecular structure is that one end of a polyethylene glycol molecular chain is connected with an acrylic acid molecule, so that after curing molding, the content of other substances except polyethylene glycol in the phase change energy storage material is extremely low; and therefore, the phase change enthalpy of polyethylene glycol is reduced to the minimum extent, and the method can be widely applied to the field of heat energy storage.

Owner:SOUTH CHINA AGRI UNIV +1

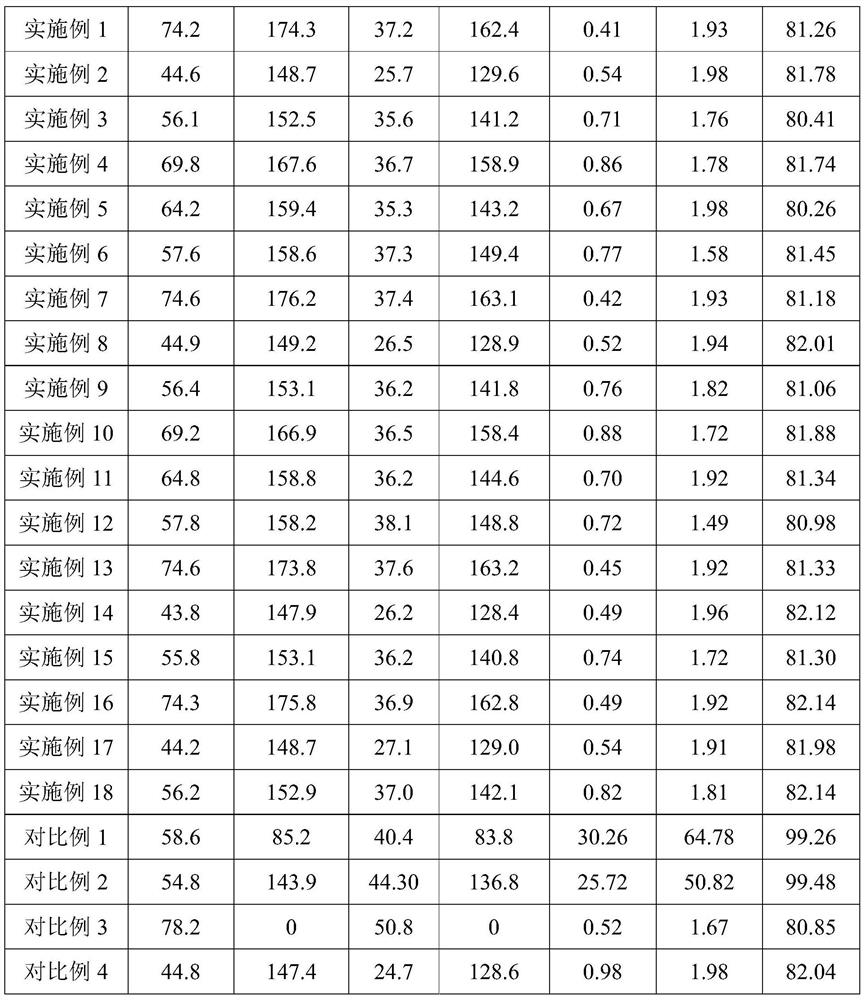

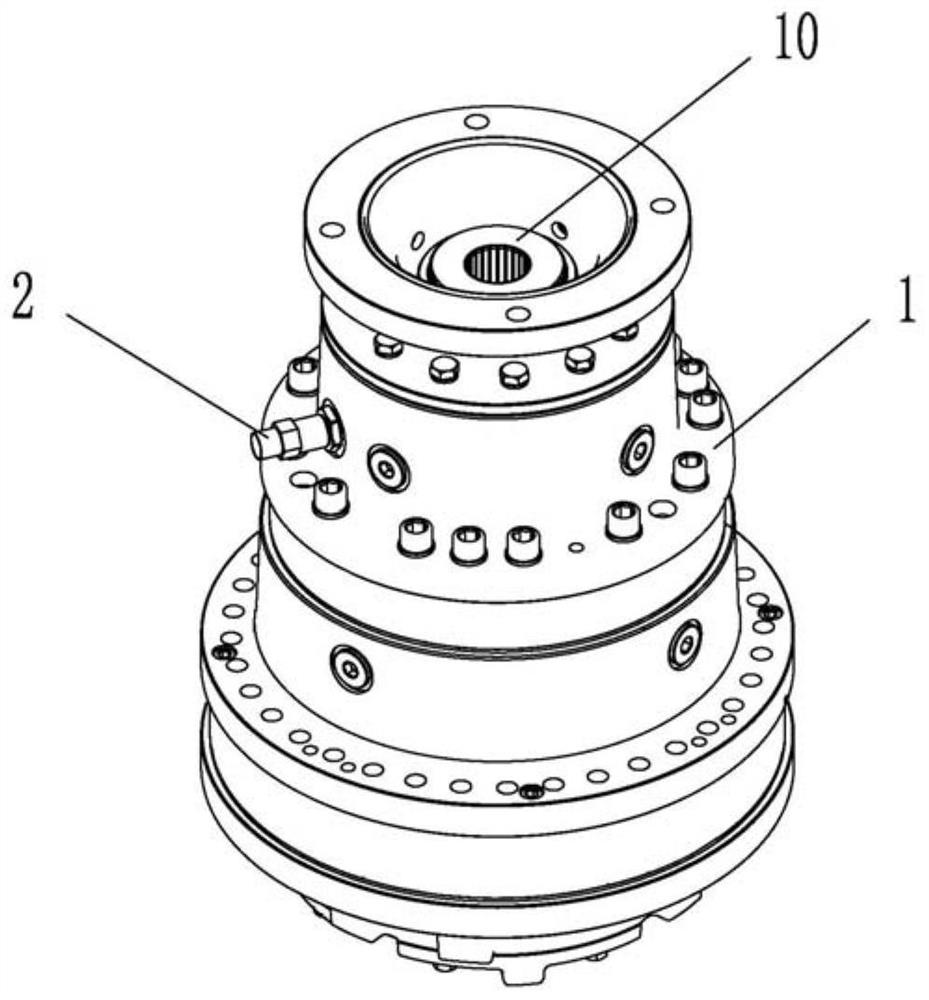

Speed reducer, driving device and rotary drilling rig

PendingCN111852319AReduce maintenance costsNo leakage issuesGearboxesConstructionsReducerHeight difference

The invention provides a speed reducer, a driving device and a rotary drilling rig, and relates to the technical field of rotary drilling rigs. The speed reducer comprises a shell and an input shaft,wherein the input shaft is arranged in the shell, the input end of the input shaft is provided with a connecting sleeve, the circumferential direction of the connecting sleeve is uniformly provided with protrusions or grooves, the position, corresponding to the connecting sleeve, of the shell is provided with a sensor, the sensing end of the sensor extends into the shell, and the sensing end senses the height difference change of the protrusions or the grooves to obtain the rotation speed of the input end. The driving device uses the speed reducer, and the rotary drilling rig uses the drivingdevice. According to the speed reducer, the driving device and the rotary drilling rig, the sensor is arranged on the shell of the speed reducer to measure the speed of the input shaft of the speed reducer, the sensor is no longer affected by temperature, and the problem of hydraulic oil leakage is avoided. In addition, the sensor is no longer affected by the temperature, the service life is prolonged, meanwhile, the maintenance cost is reduced, and then the construction efficiency is improved.

Owner:BEIJING SANY INTELLIGENT MFG TECH CO LTD

Green packaging box

InactiveCN114873060APlace stableEasy to placePackage recyclingRemovable lids/coversStructural engineeringIndustrial engineering

The invention relates to the technical field of intelligence, in particular to a green packaging box which comprises a box bottom plate, the top of the box bottom plate is fixedly connected with a box body mechanism, the box body mechanism is provided with a box cavity, a protection plate is arranged in the box cavity in a sleeved mode, an embedding opening is formed in the top of the box body mechanism, and an insertion frame is arranged in the embedding opening in a sleeved mode. When the protection plate is placed in the box cavity, the movable triangular sleeve moves towards the interior of the movable cavity under the extrusion action of the edges, so that after the movable triangular sleeve completely enters the movable cavity, the bevel edge at the bottom of the trapezoidal column makes contact with the edges, and under the extrusion action, the bevel edge at the bottom of the trapezoidal column can extrude the movable cavity towards one side; in this way, the second elastic inserting strip and the first elastic inserting strip are recycled, then the top containing plate can quickly enter the box cavity, and when the top containing plate moves to the position of the bearing clamping groove, the second elastic inserting strip and the first elastic inserting strip can be clamped in the bearing clamping groove under the elastic effect.

Owner:谢洋洋

IOS platform scheme transmission method, device, server and system

ActiveCN106156601BNo leakage issuesEnsure safetyInterprogram communicationDigital data authenticationApplication softwareUniform resource locator

The invention provides an iSO platform scheme transmitting method, device and system and a server. The method comprises the steps that a first application program obtains a token through a first protocol ordered by the first application program for the server; the first application program sends the token to a second application program through the URL scheme registered by the second application program; the second application program sends a service parameter request with the token through a second protocol ordered by the second application program for the server so as to request the server to return service parameter information relevant to the token. The server is introduced, so that only the token rather than parameter information is directly transmitted between the application programs, a hacker can only intercept the token and cannot directly obtain parameter information under the transmission mechanism even if forging application programs, the hacker cannot obtain parameter information by being ignorant of participation of the server and incapable of obtaining protocol content, and therefore information leakage can be prevented.

Owner:ALIBABA (CHINA) CO LTD

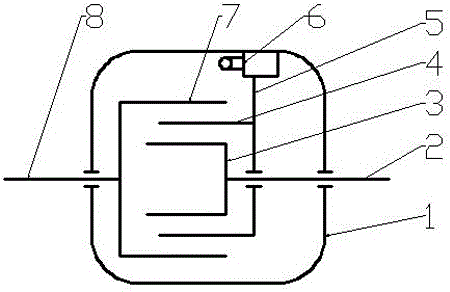

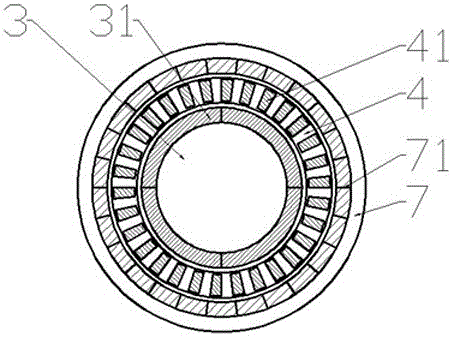

An integrated permanent magnet variable speed reducer

The invention discloses an integrated permanent magnet variable speed reducer which comprises a box (1), an adjuster (6), an input shaft (2) and an output shaft (8). The input shaft (2) is provided with a cylindrical high-speed permanent magnet motor (3) which is in synchronous rotation with the input shaft (2). The output shaft (8) is provided with a cylindrical low-speed permanent magnet motor (7) which is arranged correspondingly to the high-speed permanent magnet motor (3) and in synchronous rotation with the output shaft (8). The high-speed permanent magnet motor (3) is located in the inner cavity of the low-speed permanent magnet motor (7). A cylindrical modulation iron core (4) is arranged in the radial gap between the low-speed permanent magnet motor (7) and the high-speed permanent magnet motor (3). The modulation iron core (4) is extended into the radial gap between the low-speed permanent magnet motor (7) and the high-speed permanent magnet motor (3) or leaves from the radial gap between the low-speed permanent magnet motor (7) and the high-speed permanent magnet motor (3) through the driving of the adjuster (6). According to the invention, the infinitely variable speed function and the speed-reducing and torque-increasing function can be realized, the oil leakage problem does not exist, and advantages of energy conservation and environment protection, compact structure and high transmission efficiency can be realized.

Owner:南京艾凌节能技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com