End Cover Structure and Processing Method for Preventing Working Gas Leakage of Vertical Split Compressor

A technology of working gas and processing method, which is applied to components, mechanical equipment, machines/engines, etc. of elastic fluid pumping devices, can solve problems such as personal and property safety hazards, medium gas leakage, etc., to improve aesthetics, The effect of less processing and improvement of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

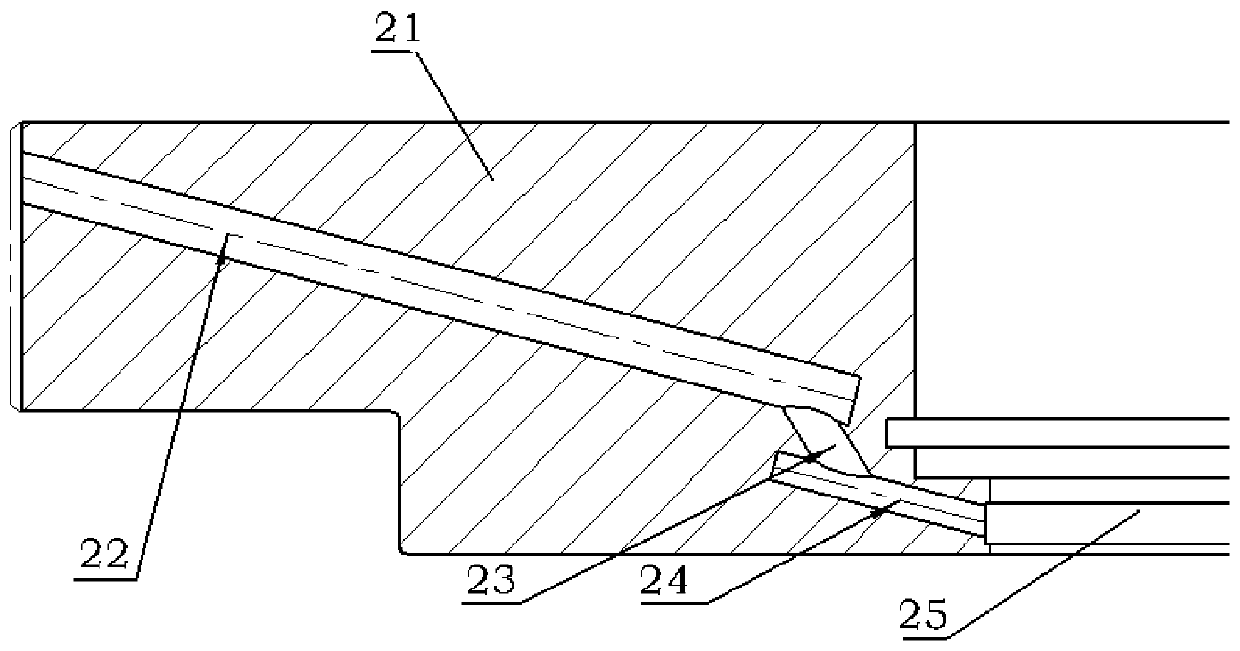

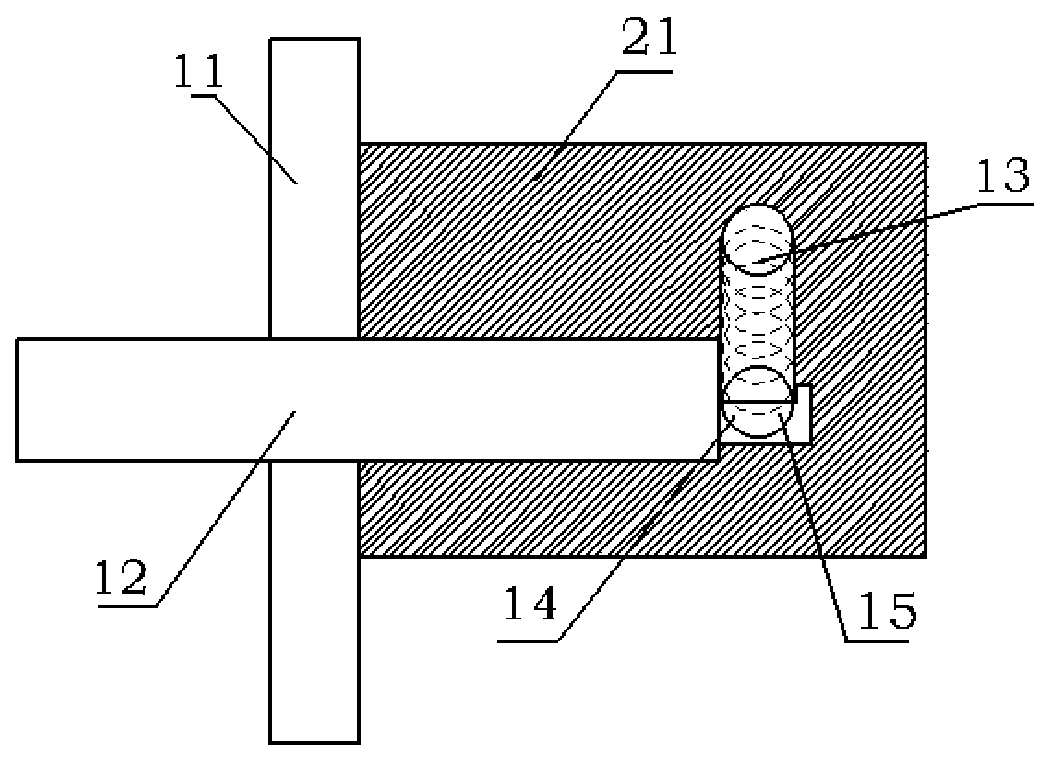

[0024] see figure 1 The embodiment of the present invention provides an end cover structure for preventing the leakage of working gas of vertically split compressors, including an end cover main body 21, an air inlet 22, a connecting hole 23 and a dry gas sealing hole provided on the end cover main body 21 24. The air inlet hole 22 communicates with one end of the connecting hole 23, the other end of the connecting hole 23 communicates with the dry gas sealing hole 24, and the dry gas sealing hole 24 communicates with the dry gas sealing area 25.

[0025] Wherein, the connecting hole 23 is an internal hole provided inside the end cap main body 21 and is connected between the air inlet 22 and the dry gas sealing hole 24 to prevent the working gas from leaking from the connecting hole 23 to the end cap main body 21 .

[0026] Wherein, in order to complete the air inlet hole 22 and the dry gas sealing hole 24 through conventional machining and reduce the processing cost, the air ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com