Speed reducer, driving device and rotary drilling rig

A technology for a rotary drilling rig and a driving device, which is applied in the field of driving devices, rotary drilling rigs and reducers, can solve the problems of small expansion space of hydraulic oil, affecting the sealing performance of sealing rings, and small size of hydraulic motor, so as to improve construction efficiency, The effect of increasing service life and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

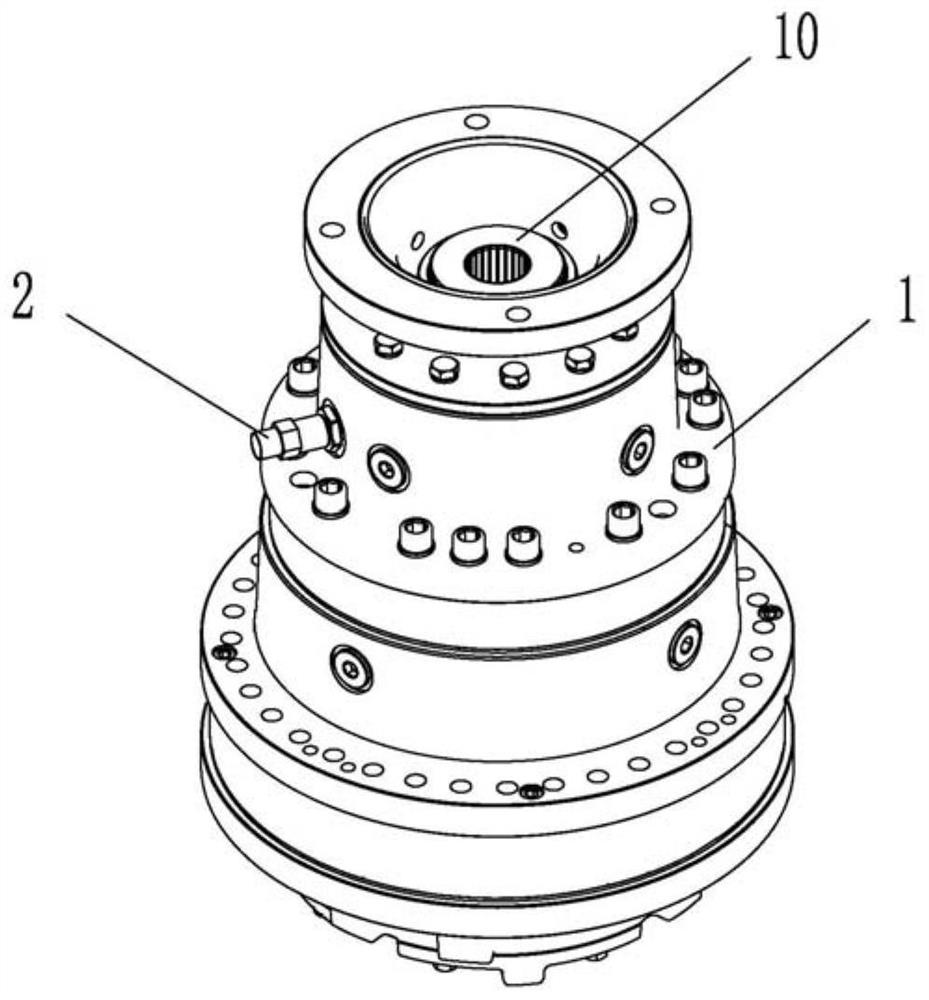

[0035] see figure 1 , The speed reducer provided in this embodiment can be applied to a rotary drilling rig, and of course it can also be used in other construction machinery. This embodiment will take a rotary drilling rig as an example to describe in detail.

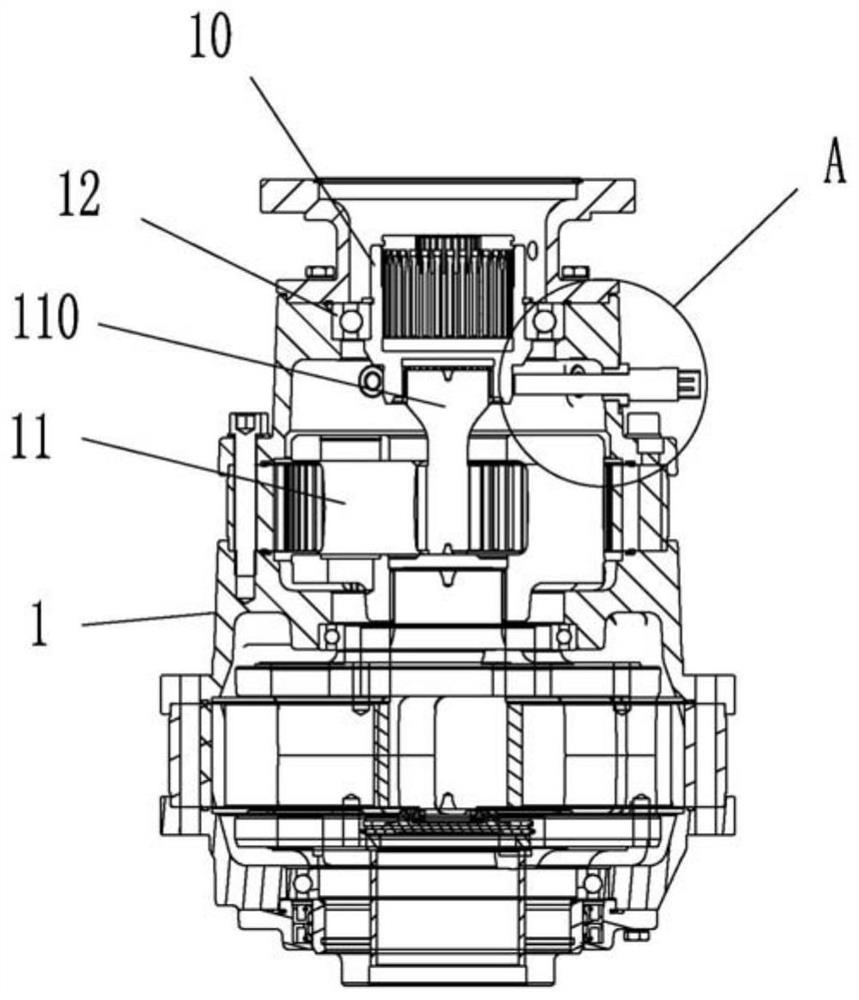

[0036] see again figure 2 The reducer provided in this embodiment includes a housing 1 and a transmission assembly 11, the transmission assembly 11 is disposed in the housing 1, and the transmission assembly 11 includes an input shaft 110 and an opposite output shaft (not shown). The input end of the input shaft 110 is used for power input, and the input power enters the transmission assembly 11 through the input shaft 110, and then is output by the output shaft of the transmission assembly 11, wherein the output power is the power for decelerating and increasing torque.

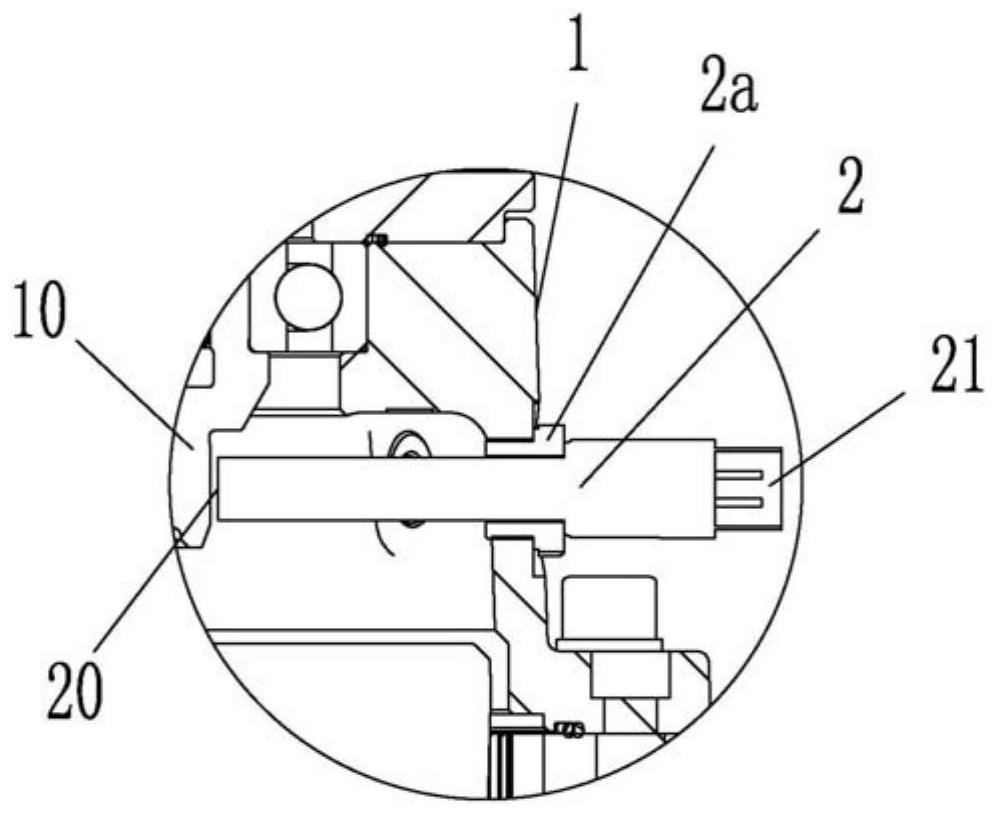

[0037] see again Figure 4 , further, the input shaft 110 is arranged in the casing 1, the input end of the input shaft 110 is provided with a co...

Embodiment 2

[0051] see Figure 1-Figure 4 , this embodiment provides a reducer, which can be applied to rotary drilling rigs, and is an improvement on the basis of Embodiment 1. Compared with Embodiment 1, the main difference is:

[0052] In this embodiment, protrusions (not shown) are uniformly provided on the circumference of the connecting sleeve 10 , and it can be understood that the height of the protrusions on the connecting sleeve 10 varies.

[0053] Wherein, the sensing end 20 of the sensor 2 faces the position where the connection sleeve 10 is provided with a protrusion, and is used for sensing the height change of the position where the connection sleeve 10 is provided with the protrusion.

[0054] This embodiment is an improvement on the basis of Embodiment 1, so this embodiment also has the following advantages: By setting the sensor 2 on the housing 1 of the reducer to measure the speed of the input shaft 110 of the reducer, power can be obtained indirectly Speed of entry ...

Embodiment 3

[0056] see Figure 1-Figure 4 , this embodiment provides a reducer, which can be applied to rotary drilling rigs. It is an improvement made on the basis of Embodiment 1 or Embodiment 2. Compared with Embodiment 1 or Embodiment 2, the main difference is:

[0057] In this embodiment, the connection sleeve 10 and the input shaft 110 cooperate with each other through flat keys, wherein the connection sleeve 10 is provided with a first key groove, and the input shaft 110 is provided with a second key groove. During installation, the flat key is installed in the second keyway, and then the connecting sleeve 10 is installed so that the first keyway on the connecting sleeve 10 is aligned with the flat key.

[0058] This embodiment is an improvement on the basis of Embodiment 1 or Embodiment 2, so this embodiment also has the following advantages: by setting the sensor 2 on the housing 1 of the reducer to measure the speed of the input shaft 110 of the reducer, The speed of the power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com