Multi-factor influence-improved ultrasonic hydraulic measurement method and system

A measurement system and measurement method technology, applied in the direction of fluid pressure measurement using acoustic methods, can solve the problems of measurement difficulty, ultrasonic echo overlap, ultrasonic probe installation deviation, etc., achieve good measurement accuracy, wide application range, improve pipe effect of diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to understand the present invention more clearly, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

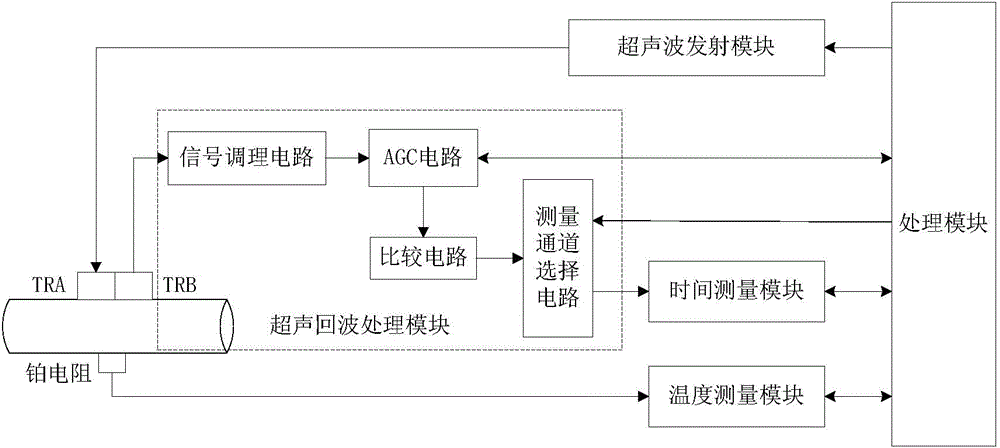

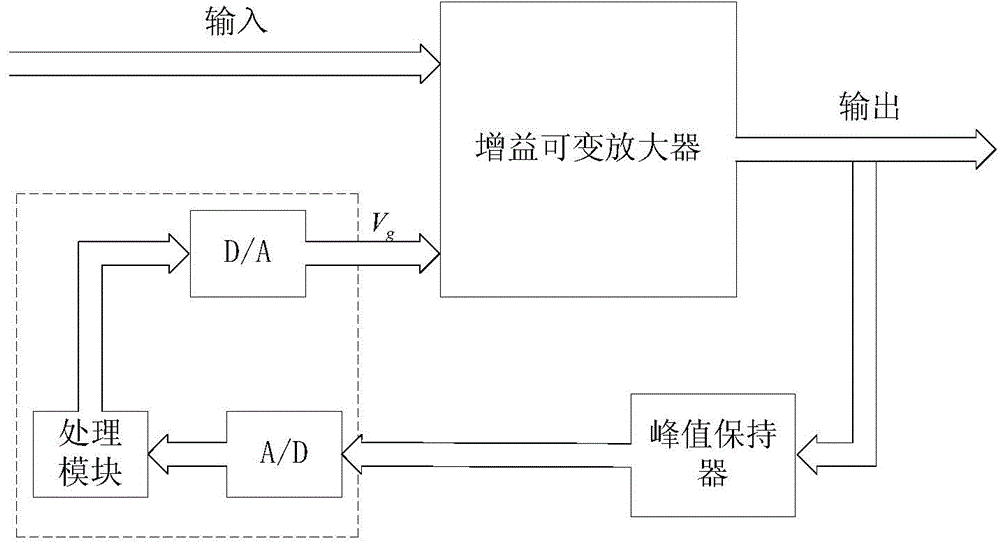

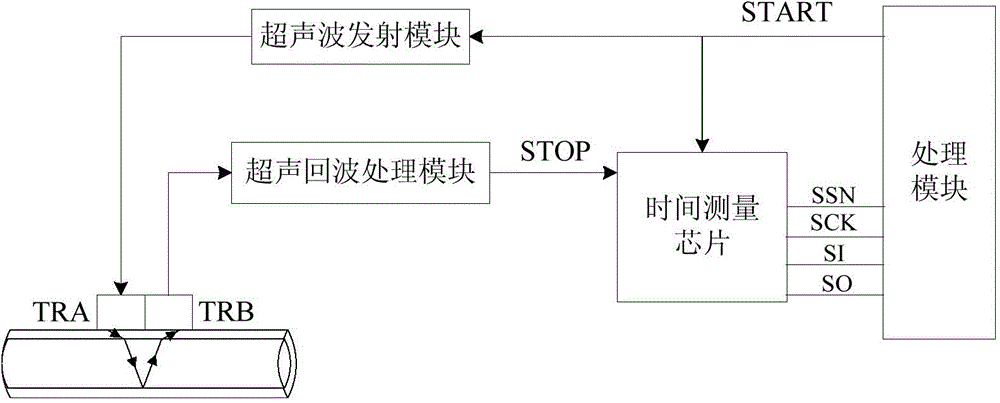

[0045] like figure 1 As shown, the present invention improves an ultrasonic hydraulic measurement system influenced by multiple factors, including an ultrasonic transmitting probe TRA, an ultrasonic receiving probe TRB, a platinum resistor, a processing module, an ultrasonic transmitting module, an ultrasonic echo processing module, a time measurement module and a temperature measurement module. module; wherein, the ultrasonic transmitting probe TRA, the ultrasonic receiving probe TRB and the platinum resistor are all arranged on the wall of the hydraulic pipe to be tested, and the processing module controls the ultrasonic transmitting module to apply high-voltage pulses to the ultrasonic transmitting probe TRA to generate ultrasonic waves, and the ultrasonic waves pass through the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com