Insulating bush made of thermoplastic material and production method thereof

A thermoplastic material, insulating sleeve technology, applied in insulators, insulators, electrical components and other directions, can solve the problems of electrical equipment insulation performance is greatly affected, epoxy resin bonding strength is not high, easy to appear pores and small cracks and other problems, Achieve the effect of neat and clean processing site, fast cooling and solidification speed, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

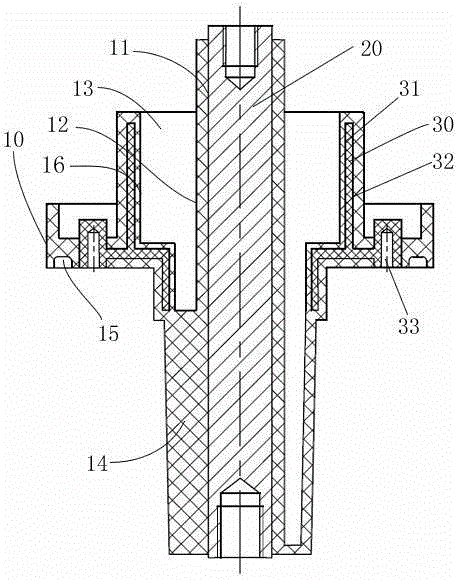

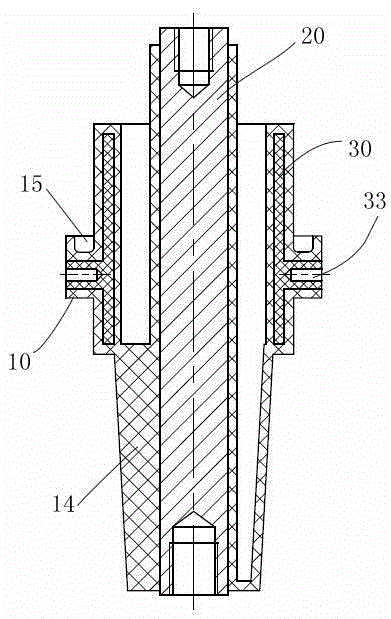

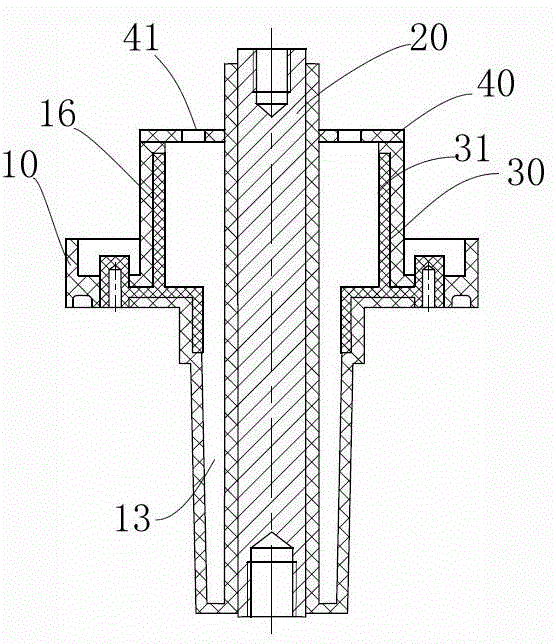

[0038] Such as figure 1 The first embodiment shown is an insulating bushing made of thermoplastic material, including an insulating casing 10, a central conductor 20 and a shielding net 30. The insulating casing 10 is cast and molded using thermoplastic materials, and the center of the insulating casing 10 is arranged along the axial direction. There is a through hole 11, the central conductor 20 is embedded in the through hole 11 of the insulating shell 10, and the two ends of the central conductor 20 are provided with mounting holes connected with cables, and the outer surface 12 of the through hole of the insulating shell 10 is insulated from the inner surface 16 of the insulating shell. In the annular cavity 13 of the shell 10, the shielding net 30 is placed in the annular cavity 13 of the insulating shell 10. The shielding net 30 is embedd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com