Film blow molding device and liquid crystal polymer film prepared therefrom

A liquid crystal polymer and film blow molding technology, applied in the field of blow molding process, can solve the problems of easy film breakage, serious film anisotropy, poor flatness of bubble film, etc., and achieve the effect of reducing the cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0072] According to one aspect of the present invention, a preparation method of the above liquid crystal polymer film, the preparation method comprises the following steps:

[0073] The molten liquid crystal polymer resin is extruded through the annular die 111, and the extruded tubular blank film is inflated under the heating gas blown by the thermal insulation blowing air ring 112 to form film bubbles; then the film bubbles are sequentially insulated by sizing The upper annular opening of the cylinder 113 and the thermal insulation box 11 reaches the pulling adjustment unit 2; then the pulling adjustment unit 2 pulls the film bubble obtained by blowing to the annealing unit 3 to obtain a formed liquid crystal polymer film.

[0074] In the preparation method of the liquid crystal polymer film provided by the present invention, the preparation method first extrudes the molten liquid crystal polymer resin through the annular die 111 , and the extruded tubular blank film is heat...

Embodiment 1

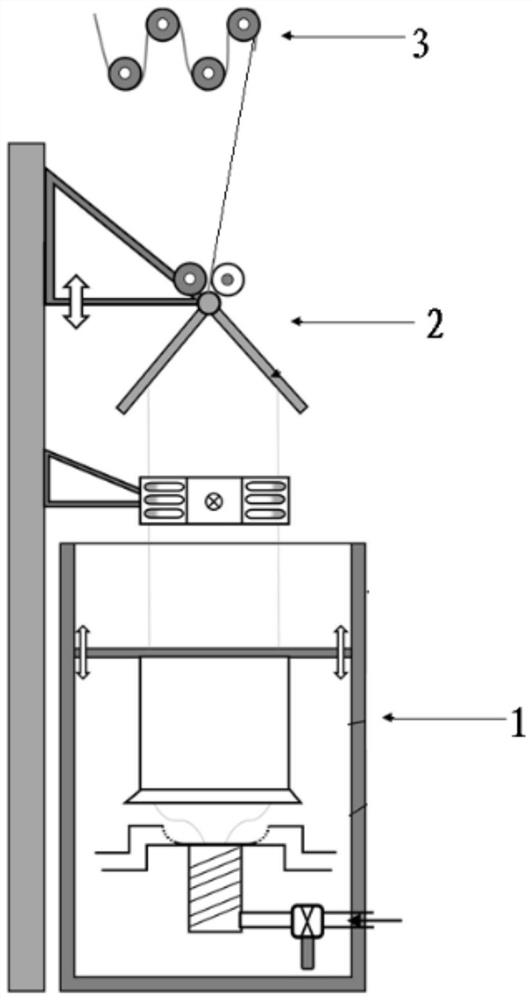

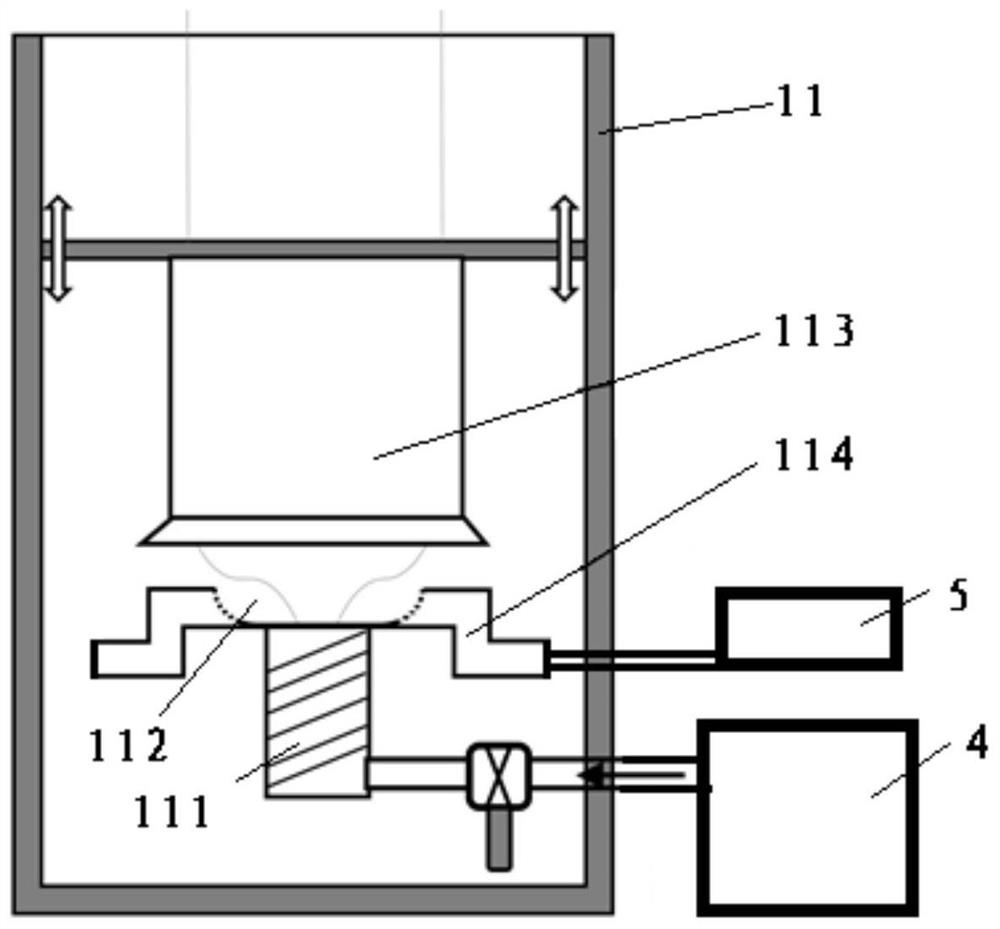

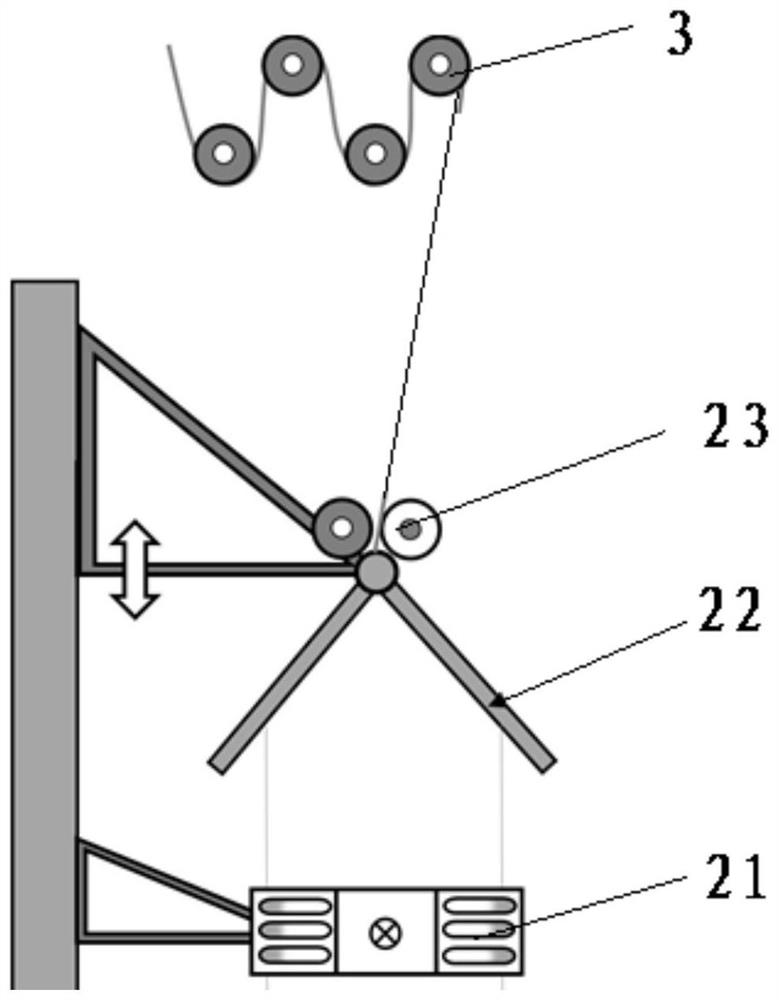

[0081] like figure 1 and figure 2 As shown, a film blow molding device includes a blow molding unit 1, a traction adjustment unit 2 and an annealing unit 3;

[0082] The blow molding unit 1 includes a thermal insulation box 11, and the thermal insulation box 11 is provided with an annular die 111, a thermal insulation blowing air ring 112 and a sizing thermal insulation cylinder 113 coaxially arranged in sequence from bottom to top;

[0083] The annular die 111 is communicated with the extrusion port pipeline of the extruder 4;

[0084] The thermal insulation blow molding air ring 112 communicates with the fan 5 through the heating pipe 114;

[0085] The traction adjustment unit 2 is arranged on the blow molding unit 1 , and the traction adjustment unit 2 pulls the film bubble obtained by blow molding to the annealing unit 3 through the annular opening provided on the upper part of the thermal insulation box 11 .

[0086]The film blow molding device of this embodiment incl...

Embodiment 2

[0105] A liquid crystal polymer film, the liquid crystal polymer film is prepared by the film blow molding device described in Embodiment 1;

[0106] The preparation method of the liquid crystal polymer film comprises the following steps:

[0107] (1) The liquid crystal polymer resin is vacuum dried in a vacuum oven, the treatment temperature is 140-160°C, and the treatment time is 4-12h. The liquid crystal polymer resin is mainly synthesized from 73% p-hydroxybenzoic acid and 27% 6-hydroxy-2-naphthoic acid by solid-phase polycondensation method, and a small amount of a third monomer can also be introduced on the basis of the above two monomers. The melting point is 280-283°C.

[0108] Subsequently, the dried liquid crystal polymer resin raw material is melted at a barrel temperature of 280-295° C. through a single-screw extruder 4 to make it uniformly plasticized. The diameter of the screw is 35 mm and the aspect ratio is 32. , remove the infusible matter and impurities thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com