A manual interlocking and locking device with three-station mechanism controlling point-to-point function

A locking device and control point technology, which is applied in the direction of electrical components, electric switches, circuits, etc., can solve the problems of inconvenient manual operation and failure to meet the user's operating conditions, and achieve complete functions, beautiful appearance, and improved reliability and quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in further detail below in conjunction with accompanying drawing:

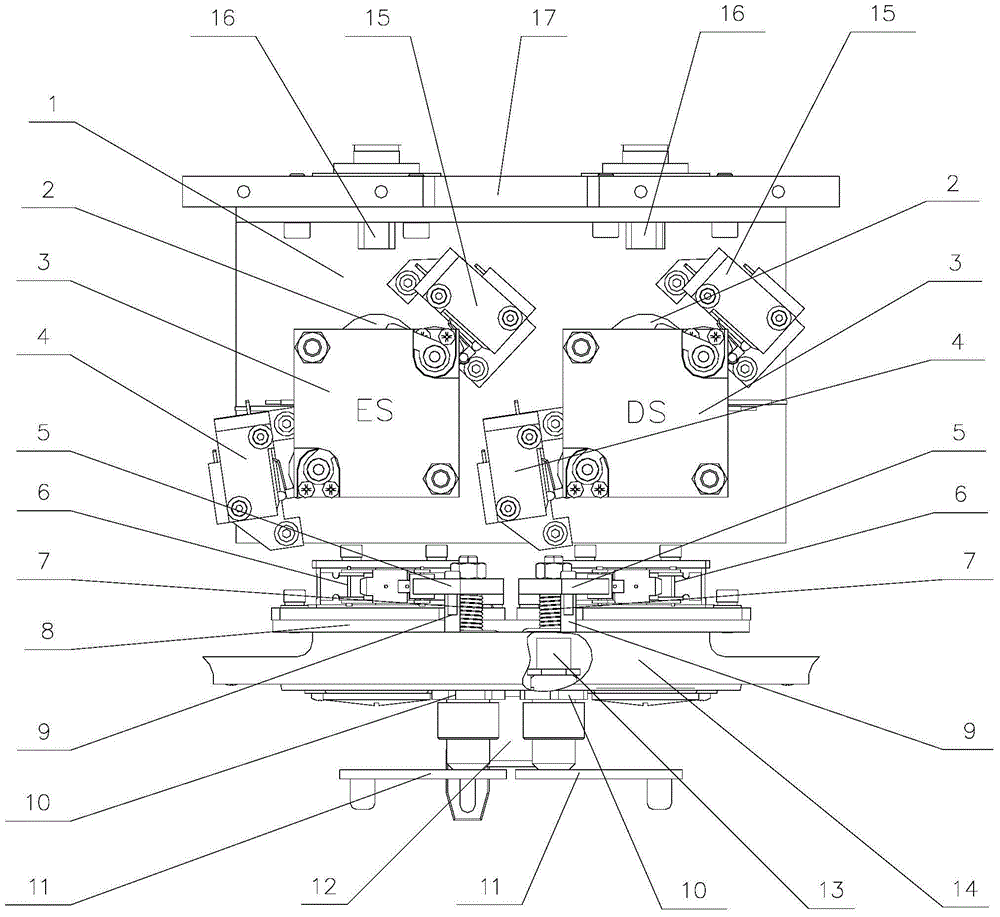

[0037] see Figure 1 to Figure 9 , the present invention includes a manual interlocking device installed on the movement side plate 17 and a manual locking device installed on the mechanism box 14;

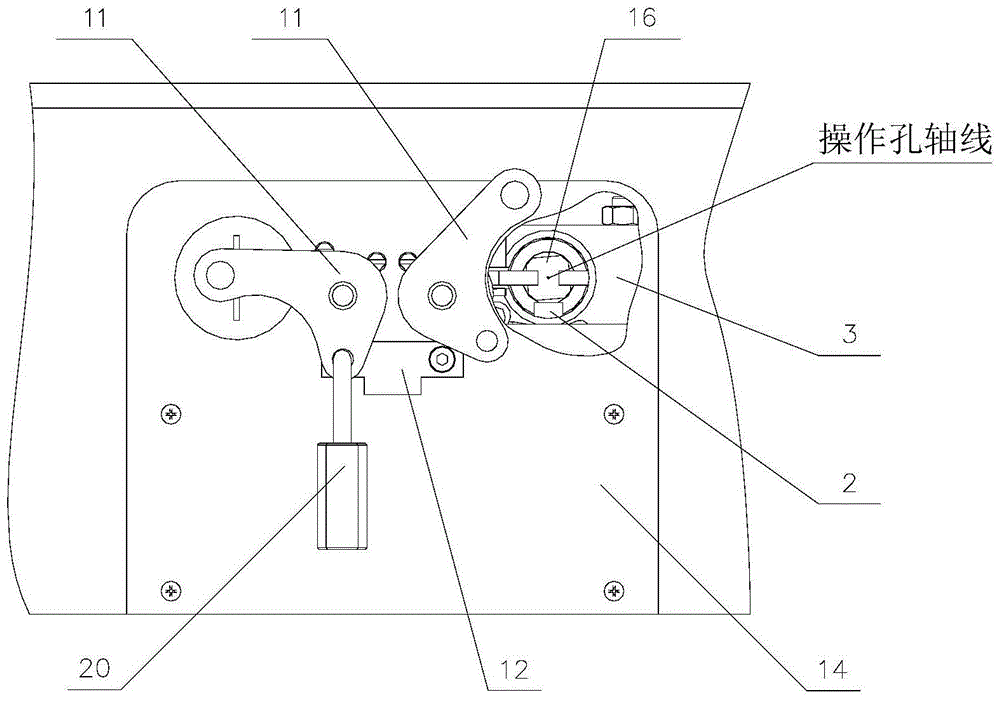

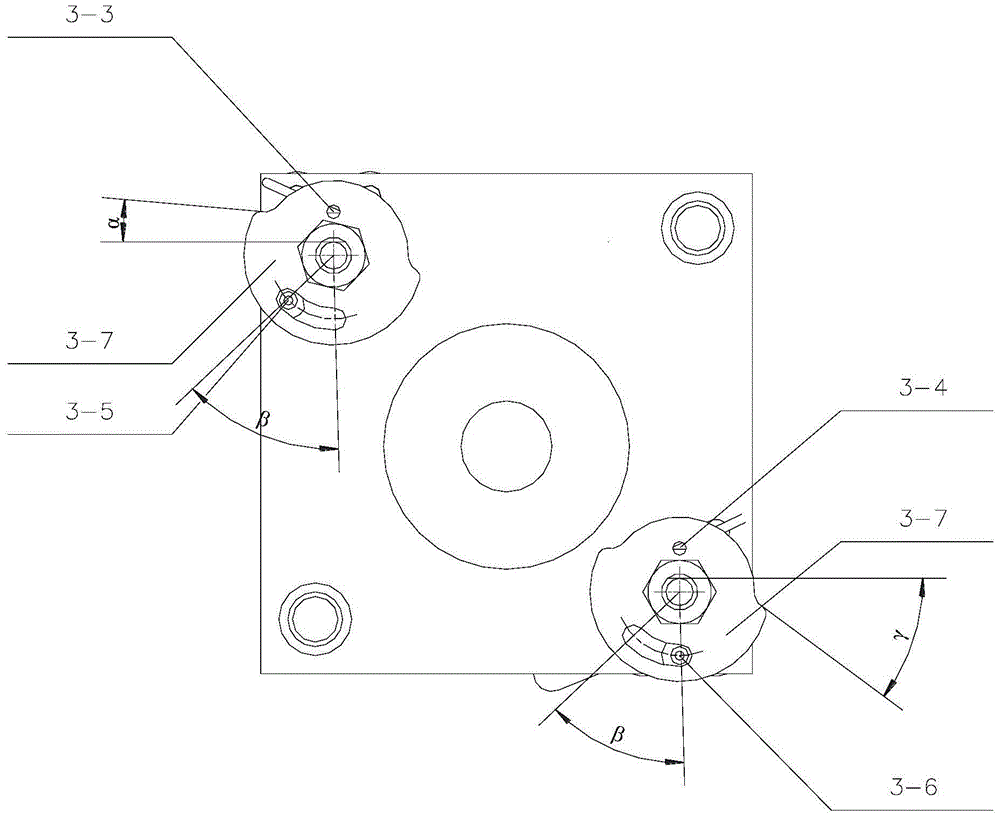

[0038] The manual interlocking device includes a support plate 1 installed on the movement side plate 17, and an interlock control module 3 installed on the DS side and the ES side of the support plate 1; the interlock control module 3 on the DS side and the ES side All are provided with an interlocking electromagnet 2 for electrically interlocking with other electrical components. The interlock control module 3 is provided with an operation hole matched with the operation handle, and the shaft of the operation hole is set coaxially with the lead screw 16 as the transmission part on the movement; An interlock power-on control switch assembly 4 and an interlock power-off ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com