Mems thermally induced vibration self-adaptive cooling method, actuator and processing method

A technology of heat dissipation method and processing method, which is applied in the direction of electric solid device, semiconductor device, metal material coating process, etc., to achieve the effect of small structure, good heat dissipation effect and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

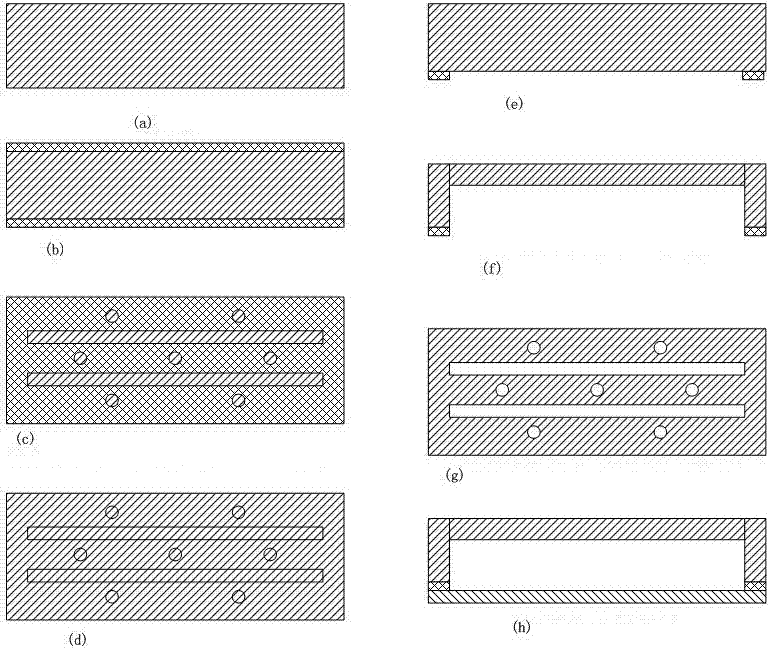

Image

Examples

Embodiment Construction

[0021] MEMS devices have the characteristics of small size, light weight, and low power consumption, which bring the following advantages to actuators based on MEMS technology: (1) Actuators with consistent performance can be obtained through batch processing, which can meet the high spatial resolution of flow control technology , high sensitivity, and high response requirements; (2) It is easy to realize the system integration of sensors, circuits and actuators, which improves the reliability and stability of the system; (3) It is easy to realize the array of actuators and realize multiple actuators The cooperative work overcomes the shortage of a single exciter with low energy. Therefore, synthetic jet technology based on MEMS technology will bring considerable prospects to the heat dissipation of large computer chassis and chips.

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] like figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com