Light emitting device and method for manufacturing the same

A light-emitting device and manufacturing method technology, applied in the field of Zener diodes and light-emitting devices, to achieve the effect of reducing the size of the frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

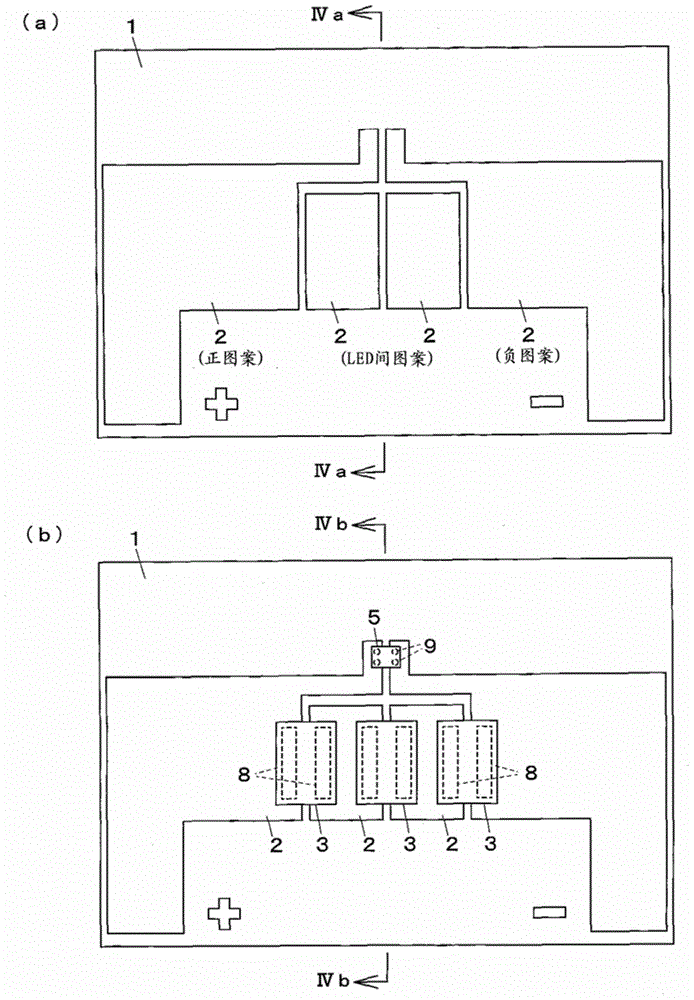

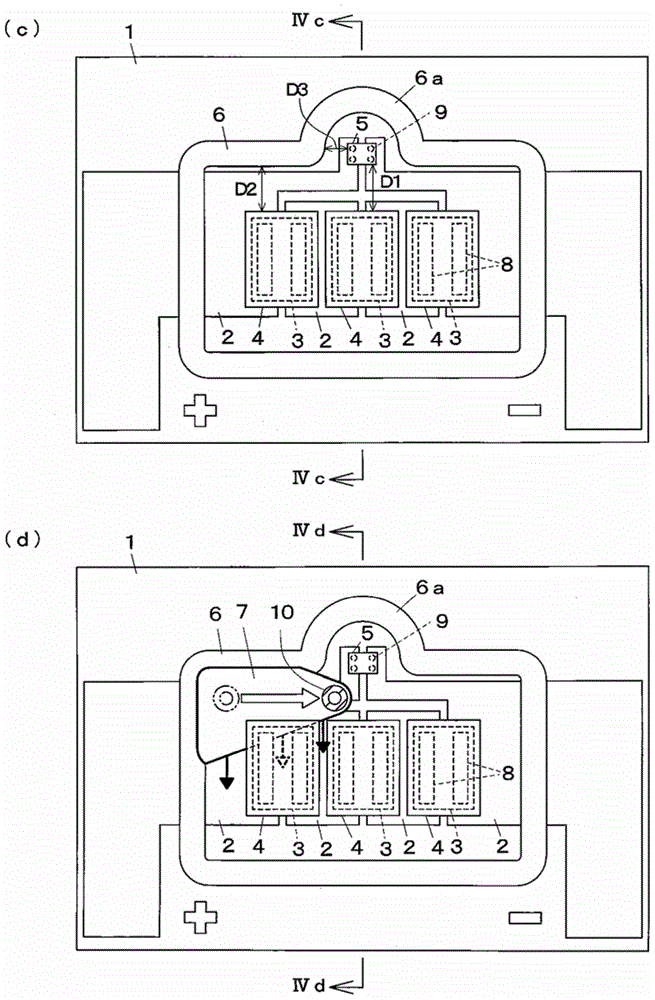

[0085] Below, refer to Figure 1 to Figure 6 Embodiment 1 in which the present invention is embodied in, for example, a light emitting device used as a light source of a headlight of an automobile will be described.

[0086] The light-emitting device includes: a substrate 1 provided with a wiring pattern 2 on the upper surface; an LED 3 emitting blue light mounted on two wiring patterns 2 at a predetermined interval; Body light-transmitting phosphor plate 4; ZD5 as a protective element of LED3 mounted on two wiring patterns 2 at a predetermined interval and next to LED3; surrounding LED3 formed on substrate 1 and the frame-shaped dam material 6 of ZD5; and the light-reflective resin 7 injected into the inner side of the dam material 6, covering the side surfaces of the LED 3 and the phosphor plate 4, and covering the side surfaces and the upper surface of the ZD5.

[0087] The substrate 1 is made of a metal excellent in heat resistance and durability, such as AlN, and is, for...

Embodiment 2

[0114] For the light-emitting device of Example 2, such as Figure 7 (a) shows the state before injecting the light-reflective resin 7, only a part of the dam 6 (central portion of one long side) is formed in a V-shape bulging outward, and a third distance is separated. It is different from Embodiment 1 in that it surrounds the three sides of ZD5. Others are the same as in Example 1, and the light-reflective resin 7 is injected in the same manner as in Example 1.

Embodiment 3

[0116] For the light-emitting device of Example 3, such as Figure 7 (b) shows the state before injecting the light-reflective resin 7, only a part of the dam 6 (one end of one long side) is formed in a U-shaped shape that bulges outward, and the second It is different from Example 1 in that the three sides of ZD5 are surrounded by three distances. Others are the same as in Example 1, and the light-reflective resin 7 is injected in the same manner as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com