A method for conductive connection of cables

A conductive connection and cable connection technology, applied in the direction of connection, circuit, electrical components, etc., can solve the problems of increased resistance, poor conductivity, inconvenient use, etc., and achieve reduced contact resistance, excellent electrical conductivity, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

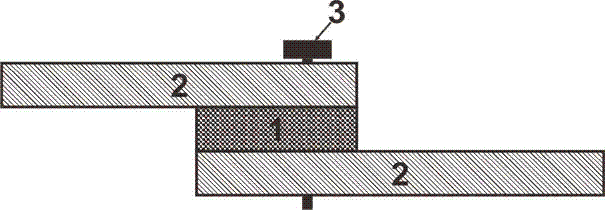

[0023] Embodiment 1 shows a typical application of the method for electrically conductive connection of cables in the present invention. figure 1 It is a schematic diagram of the application process of a method for conductive connection of cables in the embodiment. Among them: 1 is a cable, 2 is a low-melting point metal, and 3 is a fastening screw.

[0024] In this embodiment, fastening screws are used to fix the cables. The low-melting-point metal is indium-bismuth-tin alloy (the mass fraction of each component is In: 51.5%, Bi: 32%, Sn: 16.5%), and its melting point is 60°C.

[0025] When in use, after spraying molten low-melting point metal on the surface of the cable contact surface, fasten it with fastening screws. At this time, the low-melting-point metal is in rigid contact with the cable, and the air gap is large, so the contact resistance of the contact surface is large, and the heat generation is relatively large. When the temperature reaches the melting point of ...

Embodiment 2

[0027] figure 1 It is a schematic diagram of the application process of a method for conductive connection of cables in the embodiment. Among them: 1 is a cable, 2 is a low-melting point metal, and 3 is a fastening screw.

[0028] In this embodiment, fastening screws are used to fix the cables. The low-melting-point metal is indium-bismuth-tin-zinc alloy (the mass fraction of each component is In: 26%, Bi: 56%, Sn: 17%, Zn: 1%), and its melting point is 79°C.

[0029] When in use, after spraying molten low-melting point metal on the surface of the cable contact surface, fasten it with fastening screws. At this time, the low-melting-point metal is in rigid contact with the cable, and the air gap is large, so the contact resistance of the contact surface is large, and the heat generation is relatively large. When the temperature reaches the melting point of the low-melting-point metal, the low-melting-point metal melts and fills The air gap between the cables reduces the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com