Forward-reverse rotation control circuit for brush DC motor

A brushed DC motor and control circuit technology, which is applied in the direction of a single DC motor starter, motor generator/starter, etc., can solve the problems of unfavorable device miniaturization and large controller volume, and achieve volume reduction and improvement The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be specifically described below in conjunction with the accompanying drawings.

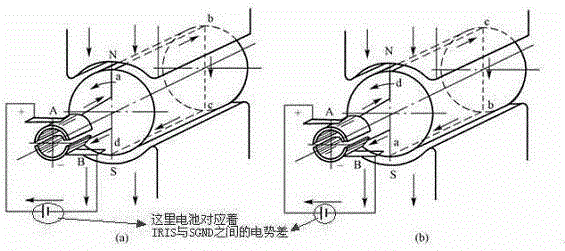

[0015] Such as figure 1 As shown, the coil abcd connects the IRIS and SGND nodes of the control circuit through the commutator and the brush, and the IRIS is figure 2 The output terminal of the class B amplifying complementary circuit is connected with the power supply ground (SGND) to connect the brushes A and B, and the positive and negative of the reference voltage corresponding to the power supply ground SGND by IRIS are used to determine the positive and negative rotation of the DC motor.

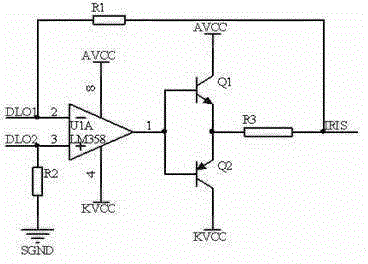

[0016] Such as figure 2 As shown, the forward and reverse control circuit of the present invention includes a comparator U1A and a Class B amplifier circuit, and the output of the comparator U1A drives the Class B amplifier circuit to supply power to the motor. The comparator U1A has two complementary inputs DLO1 and DLO2. The output of the comparator U1A is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com